Adjustments, Boom height, Nozzle pressure – Great Plains CF60 Operator Manual User Manual

Page 20: Leveling the boom, Boom fold, Break-away spring, Fold bracket, Spring arm tension

CF50 and CF60

500-015M

4/16/2003

18

Adjustments

Boom Height

After calibrating sprayer for the specific nozzle to be used

at a desired pressure, and tractor speed, the main field ad-

justment is boom height. Refer to Elevator Option in the

sprayer owner’s manual. Depending on which type of noz-

zle used, set boom height to achieve correct overlap for

that specific nozzle. If the crop canopy is taller in some

fields than others, adjust boom height accordingly. Refer

to nozzle tables in the Application Guide to determine

the height of the boom needed.

EXAMPLE: A 2.5 Metercone nozzle at 20 inch spacing is

being used. From the nozzle chart, a height of 19 to 21

inches above the top of the crop is required. If the crop is

6 inches off the ground, the boom height should be set to

25 to 27 inches off the ground.

Nozzle Pressure

Another area that will need some field adjustments is noz-

zle pressure. As tank level decreases, adjust the boom

pressure to keep the pressure at the same magnitude for

what the sprayer was calibrated for. Watch the pressure

gauge and be aware of changes in pressure.

Leveling the Boom

For even application, the sprayer boom must be level

across the span. The boom is initially leveled during as-

sembly. You may need to make additional adjustments to

level the boom. To level the boom, refer to Leveling the

Boom, Preparation and Setup, page 14.

Boom Fold

If boom is not folding squarely into the fold rest as it should

due to damage on boom or some other reason, the boom

fold will need to be adjusted. Fold boom wing to a position

just above the stop rest. Slightly loosen the four adjust-

ment plate nuts until boom wing can move. Position boom

wing to stop square in the rest stop and retighten adjust-

ment plate nuts to 150 foot pounds. Make sure the

adjustment plate is adjusted so there are no gaps between

the ball joints of hinge and hinge tubing on boom wing. Un-

fold boom wing and re-torque adjustment plate nuts again.

Break-Away Spring

The break-away spring is located near the hinge for the

outside boom arm. On early models the break-away

spring should be compressed to a length of 5 3/8 inches.

On later models tighten the nuts that compress the spring

until all threads are bottomed out.

Fold Bracket

The fold brackets hold outside boom arm up when boom is

in the folded position. These brackets are initially posi-

tioned at the factory at an optimum position so when boom

is unfolded, the fold brackets will not interfere with spray

pattern. The brackets need to be positioned so both por-

tions of the bracket are located the same distance from the

adjacent nozzle. The bracket also needs to be positioned

so when boom is folded, the outer boom wing rests on the

fold rest, not on break-away nuts located near the hinge

point of outer boom wing. If the outer boom wing is resting

on the nuts, they will damage tubing on boom.

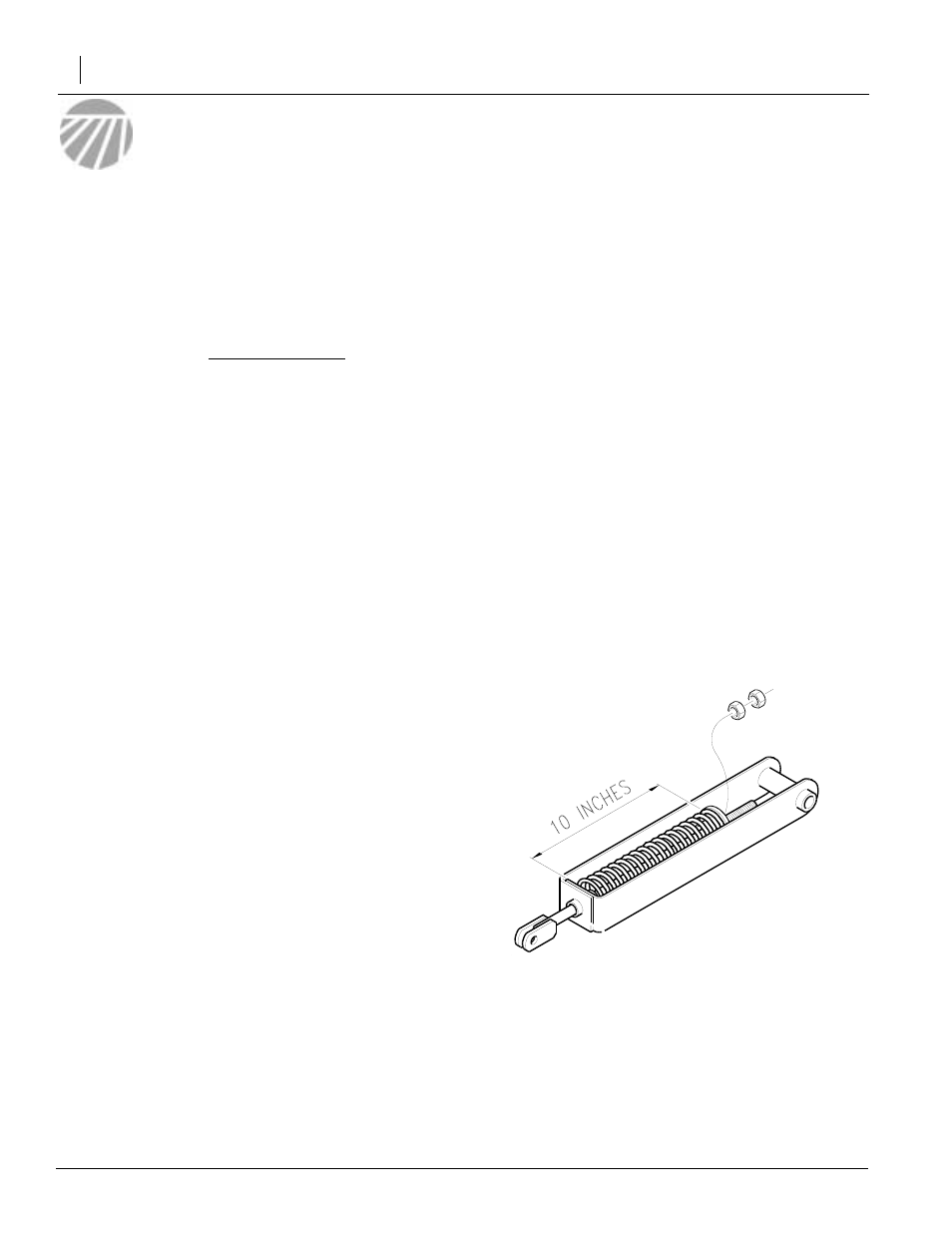

Spring Arm Tension

Refer to Figure 8

Tighten the spring nut until spring is compressed to a

length of 10 inches. Lock with second nut.

Figure 8

Spring Arm Adjustment

11937