Dual flat fold marker hydraulic assembly, Assembly instructions – Great Plains 2600-2S Assembly Instructions User Manual

Page 3

3

2/28/2006

3000-3S and 2600-2S Marker Option 113-561M

Great Plains Mfg., Inc.

Assembly Instructions

3.

Route 252" long hose (#3) from the center of the drill to the

marker base end fitting. Route 272" long hose (#4) from the

center of the drill to the needle valve (#7) at the marker rod

end fitting. Route the marker hoses along the same path as

the opener lift hoses, allowing the same slack at the drill

toolbar pivots as the other hoses. Use the rubber hose pro-

tectors and hose clamp brackets which are already bolted to

your drill to secure the hoses in place. DO NOT alter the

routing or amount of hose slack of the existing hoses when

you loosen the clamp brackets to insert the marker hoses.

Tie the marker hoses to the opener lift hoses at the toolbar

vertical and horizontal pivots with cable ties (#16).

4.

Route the 348" long hoses (#5) down the center of the

tongue tube and connect them to the hoses (#3) and (#4)

with JIC adapters (#8) at the center of the center box sec-

tion. Make sure the hoses do not interfere with the center

clutch assembly.

5.

Bolt the selector valve (#10) to the valve mount bracket

(#17) on the tongue tube with the 3/8" x 3 1/4" long bolts

(#13), 3/8" lock washers (#14), and 3/8" hex nuts (#15). In-

stall the 1/2" FNPT adapters (#9) to the front and rear ports

of the selector valve (#10) and the 3/4" JIC elbows (#12) to

the cross ports. Assemble the 96" long 3/8" hoses (#11) to

the elbows (#12) on the selector valve.

6.

Connect the 348" long hoses (#5) to the rear adapters on

the selector valve (#10). Connect the long hoses from the

fold hydraulic circuit to the front adapters on the selector

valve. Secure the four 1/4" hoses going into the selector

valve to the top of the tongue with the hydraulic hose guards

(#18), the hose clamp brackets (#19), the 5/16" x 2 1/2" bolts

(#21), and 5/16" lock washers (#20). The 5/16" bolts screw

into the nuts which are welded to the top of the tongue tube.

7.

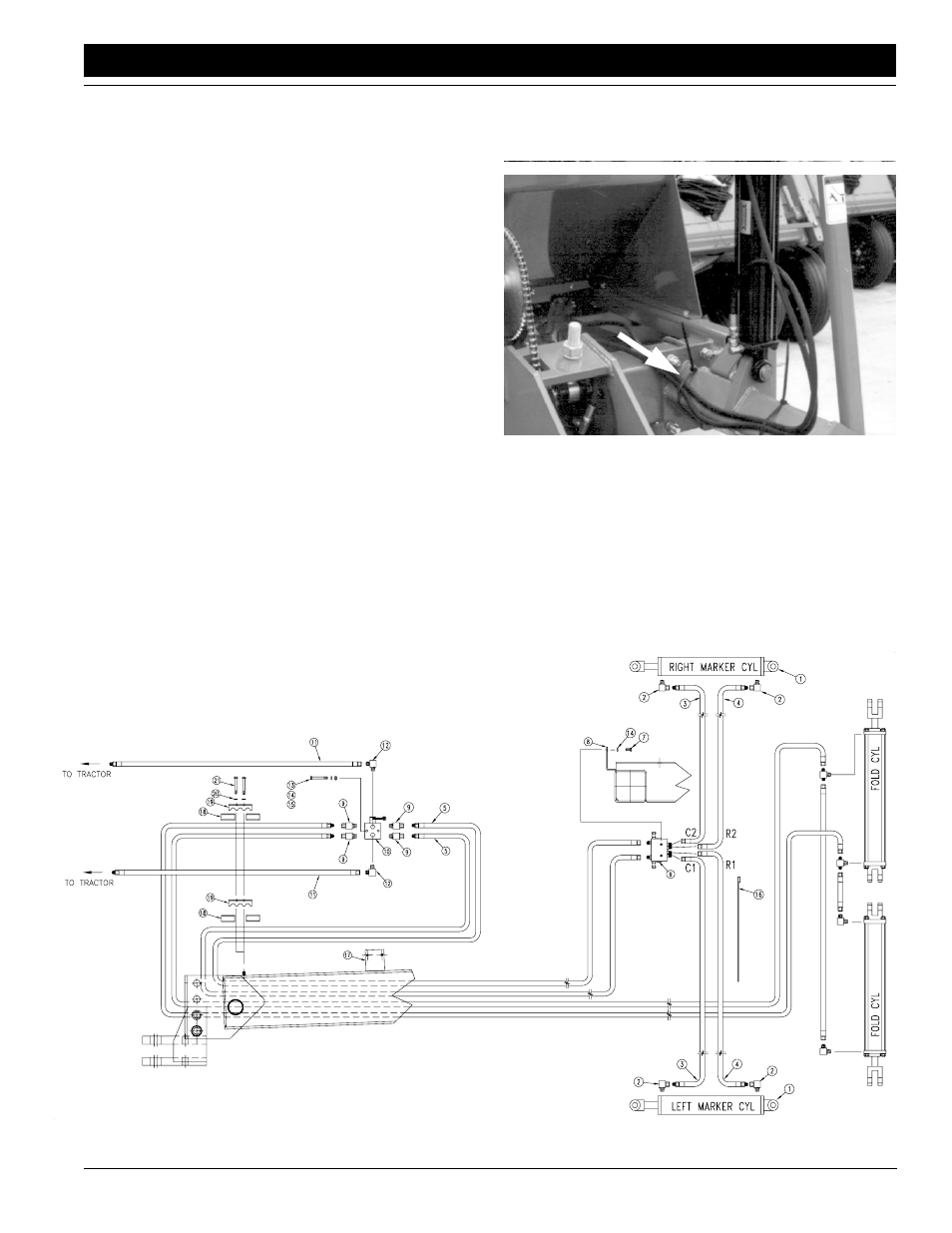

Tie the hoses down with plastic cable ties (#16) to prevent

pinching or kinking of hoses during the folding operation.

Tieing the hydraulic hoses to the marker mount tube as

shown in Figure 3 is the preferred way to assure that they

will flex properly and not get pinched by the marker first sec-

tion.

IMPORTANT: BEFORE FOLDING THE MARKER, BLEED ALL

THE AIR OUT OF THE HYDRAULIC SYSTEM.

8.

Bleed the marker hydraulic system as described in the drill

OPERATOR’S MANUAL.

9.

Set the marker raise and lower speeds as described in the

drill OPERATOR’S MANUAL.

Dual Flat Fold Marker

Hydraulic Assembly

Refer to Figure 4:

1.

Assemble elbows (#2) to the hydraulic cylinder ports.

2.

Route 272" long hoses (#3) from the center of the drill to the

marker rod end fittings. Route 252" long hose (#4) from the

center of the drill to the marker base end fitting. Route the

marker hoses along the same path as the opener lift hoses,

Hydraulic Hose Routing at Marker Mount

Figure 3

15530

15686

Dual Marker Hydraulics

Figure 4