Great Plains NTA2007 Material Rate User Manual

Page 11

Great Plains Manufacturing, Inc.

Setting Meter Rate

9

2012-01-03

167-085B

8.

Accurately weigh an empty container large enough

to catch material coming out of the meter. The

calibration bag supplied with your cart or drill weighs:

9.

As needed, on models with calibration chutes,

deploy or install the chute.

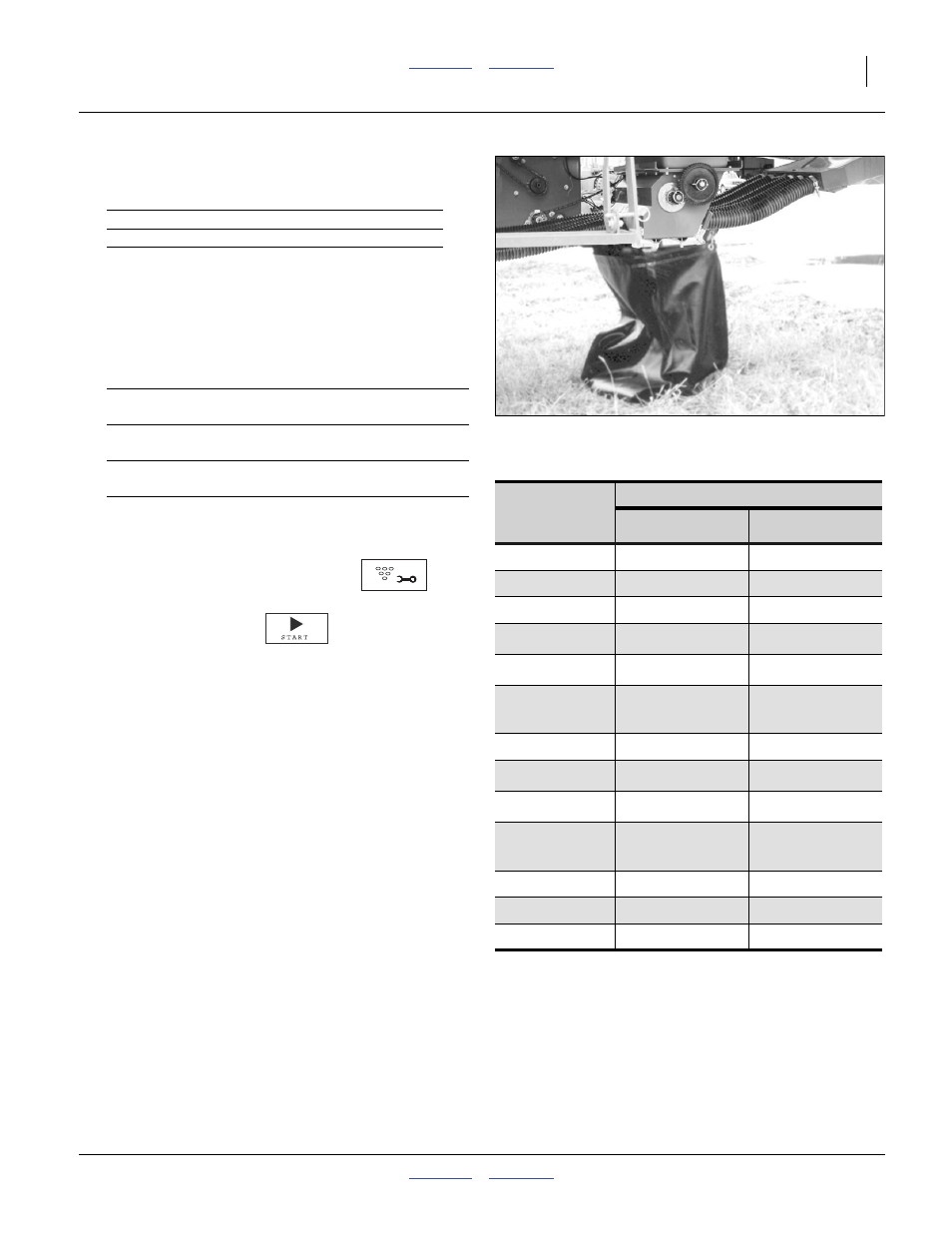

Refer to Figure 11 (which depicts a meter without guards - if

your cart included guards, do not operate without them)

10. Place calibration bag under open calibration door or

onto the calibration chute:

11. On the seed monitor terminal,

set the monitor to Calibration mode

.

enter [ 5 ] for the “# Meter Revs”, and

press the Start softkey

.

This “# Meter Revs” parameter does not affect the

monitor calibration because the monitor counts

actual meter shaft revolutions and uses that count to

compute the Calibration Constant.

The “# Meter Revs” parameter is used for a progress

bar displayed during calibration.

12. Turn the calibration crank for the number of turns to

simulate

1

⁄

10

hectare (or

1

⁄

10

acre). See table at right

for the correct number of turns for your implement.

Note: A longer calibration is always more accurate,

especially for low rates and small seeds.

1

⁄

10

hectare or acre is easy to calculate and is a

minimum calibration run.

Note: It is important to turn the calibration crank rapidly.

For ADC2350, ADC2350B, NTA907/HD and

NTA3007/HD, about 2 to 2

1

⁄

2

revolutions per

second is the proper speed to simulate

8 to 9.6 kph (5 to 6 mph) planting speed.

For NTA607/HD and NTA2007/HD, about 1 to 1

3

⁄

4

revolutions per second is the proper speed to

simulate 6.7 to 11.8 kph (4.2 to 7.3 mph).

ADC2350/B:

1.52 Kg (3.36 lbs)

NTA607/2007/HD:

0.91 Kg (2.0 lbs)

NTA907/3007/HD:

1.52 Kg (3.36 lbs)

ADC2350:

ADC2350B:

Loop bag handles over door handles

and hook bag to front of the meter.

NTA607/HD:

NTA2007/HD:

Deploy calibration chute. Attach bag

to end of chute.

NTA907HD:

NTA3007HD:

Loop bag handles over door handles

and hook bag to front of the meter.

NTA907:

NTA3007:

Install calibration chute. Attach bag to

discharge end of chute.

Figure 11

Calibration Bag

26402

Drill Model

Clutch Shaft (Crank) Revs for…

1

⁄

10

Hectare

1

⁄

10

Acre

3N-4010HDA

76

1

⁄

2

31

CTA4000

75

1

⁄

2

30

1

⁄

2

CTA4000HD

75

1

⁄

2

30

1

⁄

2

NTA607

a

a. The implement or drill Operator Manual provides

more precise crank counts, which vary slightly with

row spacing, wing flex option and pass/bout gap.

86

1

⁄

4

35

NTA607HD

86

1

⁄

4

35

NTA907

113

b

105

c

b. Counted at jackshaft.

c. Counted at contact wheel.

45.9

42

1

⁄

2

NTA907HD

105

42

1

⁄

2

NTA2007

86

1

⁄

4

35

NTA2007HD

86

1

⁄

4

35

NTA3007

105

45.9

42

1

⁄

2

NTA3007HD

105

42

1

⁄

2

NTA3010

102

41

1

⁄

4

NTA3510

77

31

1

⁄

4