Calibration crank, Refer to figure 8 – Great Plains NTA2007 Material Rate User Manual

Page 10

8

Great Plains Manufacturing, Inc.

VRG Air Drills

167-085B

2012-01-03

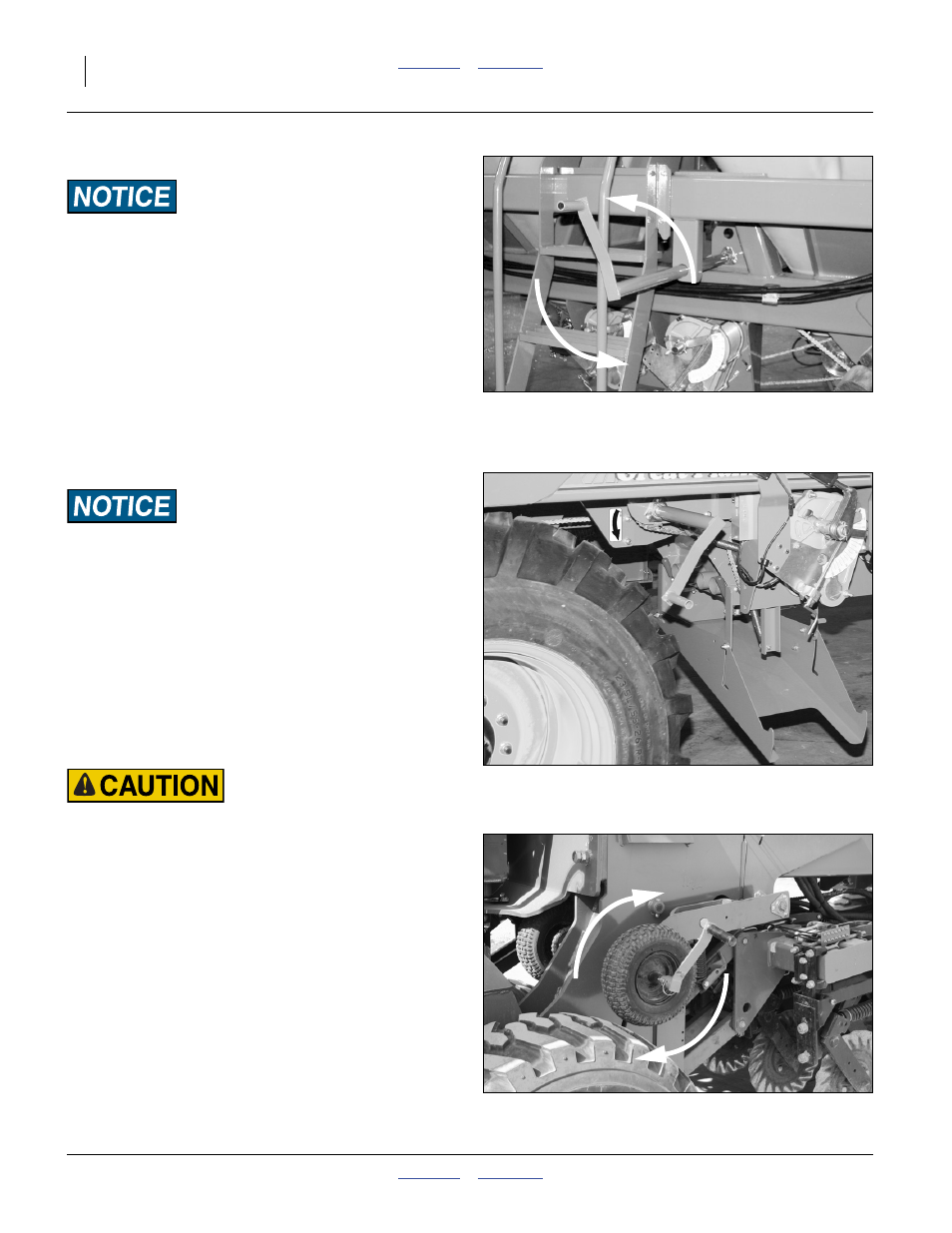

Calibration Crank

Loss of Material Risk:

Do not open the door under the DRIVING gear. This is the

clean-out door. Opening this door drains the hopper. Once the

clean-out door is open it is difficult to stop seed flow until the

hopper is empty, and impossible to close it with a seal tight

enough for application.

Refer to Figure 8 or Figure 10

5.

Mount calibration crank:

ADC2350/B: onto clutch shaft. See “Meter Hand

Crank” in air cart Operator Manual for operations.

NTA907/3007/HD: onto contact drive shaft. See

“Calibration Crank” in Operator Manual for

operations.

Machine Damage and Rate Risks:

Rotate calibration crank only in the correct direction:

ADC2350/B:

COUNTERCLOCKWISE

NTA607/2007/HD

COUNTERCLOCKWISE

NTA907/3007/HD:

CLOCKWISE on left side, at contact

drive (as shown in Figure 10) or at

jackshaft (2012+ models),

COUNTERCLOCKWISE on right side

at contact drive

Operating in reverse can cause gearbox damage.

6.

Turn the calibration crank enough turns to be sure

the meter flutes are full and the system is metering.

Possible Agricultural Chemical Hazards:

Obey manufacturer or grower recommendations for safety

equipment and protective gear when using treated seeds.

7.

Wipe all material off the flanges around the meter

door.

Figure 8

ADC2350/B Calibration Crank

26333

Figure 9

NTA607/2007/HD Calibration Crank

31171

Figure 10

NTA907/3007/HD Calibration Crank

29417