Great Plains TS1000 Trailer Sprayer Operator Manual User Manual

Page 31

Great Plains Mfg., Inc.

Maintenance and Lubrication

7/6/09

29

TS1000 Trailer Sprayer 500-111M

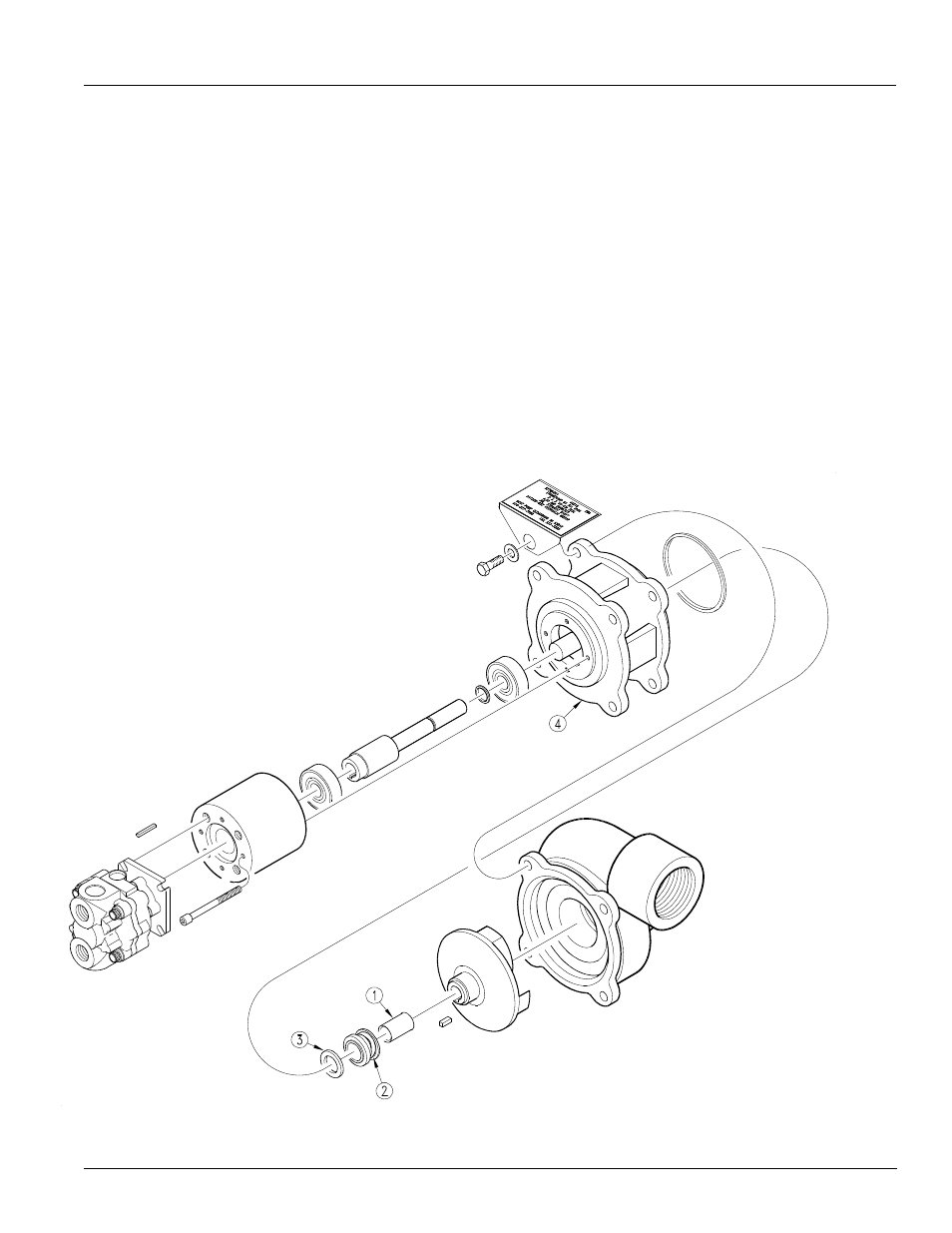

touch the white ceramic seat face.

5.

Assemble the impeller, being careful not to jar the me-

chanical seal that has been positioned on the pump

shaft.

6.

Assemble the rest of the pump.

14418

Figure 22

Scott Pump Seal Replacement

Scott Pump Seal Replacement

Refer to Figure 22

The following are instructions for how to reassemble the

pump after it has been disassembled and repaired. Refer

to the parts manual for the components of the pump.

If seal replacement is required:

1.

Disassemble pump and clean all components.

2.

Assemble the ceramic ring seat of the mechanical

seal (3) into the adapter (4) of the pump. Make sure

the ceramic seat is positioned square into the volute

housing.

3.

Clean off any grease or dirt from the pump sleeve (1)

and dry the sleeve so the rubber bellows on the me-

chanical seal will adhere to the sleeve properly when

assembled.

4.

Assemble the seal (2) with its spring, on the sleeve by

pushing on the inside rubber portion of the seal using

water as the lubrication. Make sure to align the notch-

es in the mechanical seal with the notches in the

sleeve. Assemble the mechanical seal/sleeve assem-

bly on the pump shaft. The graphite seal face should