Active hydraulic system – Great Plains 2S-2600F Operator Manual v2 User Manual

Page 39

37

Section 3 Adjustments

9/26/13

2S-2600 and 2S-2600F Two-Section Folding Drill 195-200M-A

Great Plains Mfg., Inc.

Active Hydraulic System

To run the drill with constant opener down pressure re-

quires an Active Hydraulic System. An Active Hydraulic

System requires a tractor with closed-center hydraulics or

pressure/flow compensated hydraulics powered by a vari-

able displacement hydraulic pump. (If you are not familiar

with your tractor's hydraulics, consult your tractor dealer.)

NOTE: To run the drill on tractors with open-center hydrau-

lics or on tractors with fixed displacement hydraulic pumps

you must install a Great Plains kit, part number 194-143A.

Contact your Great Plains dealer for ordering information.

Refer to Non-Active Hydraulics System on this page.

To set down pressure:

1.

Lower openers to the ground. Lock hydraulic lever for-

ward for constant hydraulic flow.

John Deere tractors with Sound-Gard ® Body: Use

lever lock clip, John Deere part number R52667, to

lock lever forward. See your tractor dealer for clip pur-

chase and installation.

John Deere 7000 Series tractors: Rotate valve

detent selector to motor position to lock lever in for-

ward position.

John Deere 8000 Series tractors: Set timer to con-

tinuous. Push lever forward until detent clicks.

Case-IH Magnum tractors: Lock lever forward in

detent position. You may need to turn up detent pres-

sure to its maximum setting. Do not tie hydraulic lever

past detent position with a strap. See your tractor

dealer for hydraulic-system details.

Other tractors: Lock lever forward in detent position.

You may need to turn up detent pressure to maximum

or use a mechanical detent holder to hold lever for-

ward. See your tractor dealer for proper means of pro-

viding constant flow to openers.

2.

Turn knob on pressure-control valve, see Figure 3-15.

While watching pressure gauge, turn knob until gauge

shows desired pressure. Turn clockwise to increase

pressure. Turn counterclockwise to decrease pres-

sure.

There is one pressure-control valve for openers on the

inside of drill and one for openers on the outside ends.

As a general starting point, set hydraulic down pres-

sure to 800 psi. For most field conditions, adjust down

pressure between 200 and 1400 psi. Setting the open-

er down pressure above 1700 psi. will raise the drive

wheels off the ground when the seed box is empty

causing skips and poor seed metering. Refer to the

IMPORTANT: Tractors with load-sensing hydraulics

must use the bypass valve to operate the 2600-3S. Fail-

ure to use the bypass valve can cause major tractor

damage. Before adjusting opener down pressure, set

bypass valve as explained under Setting the Bypass

Valve, page 16.

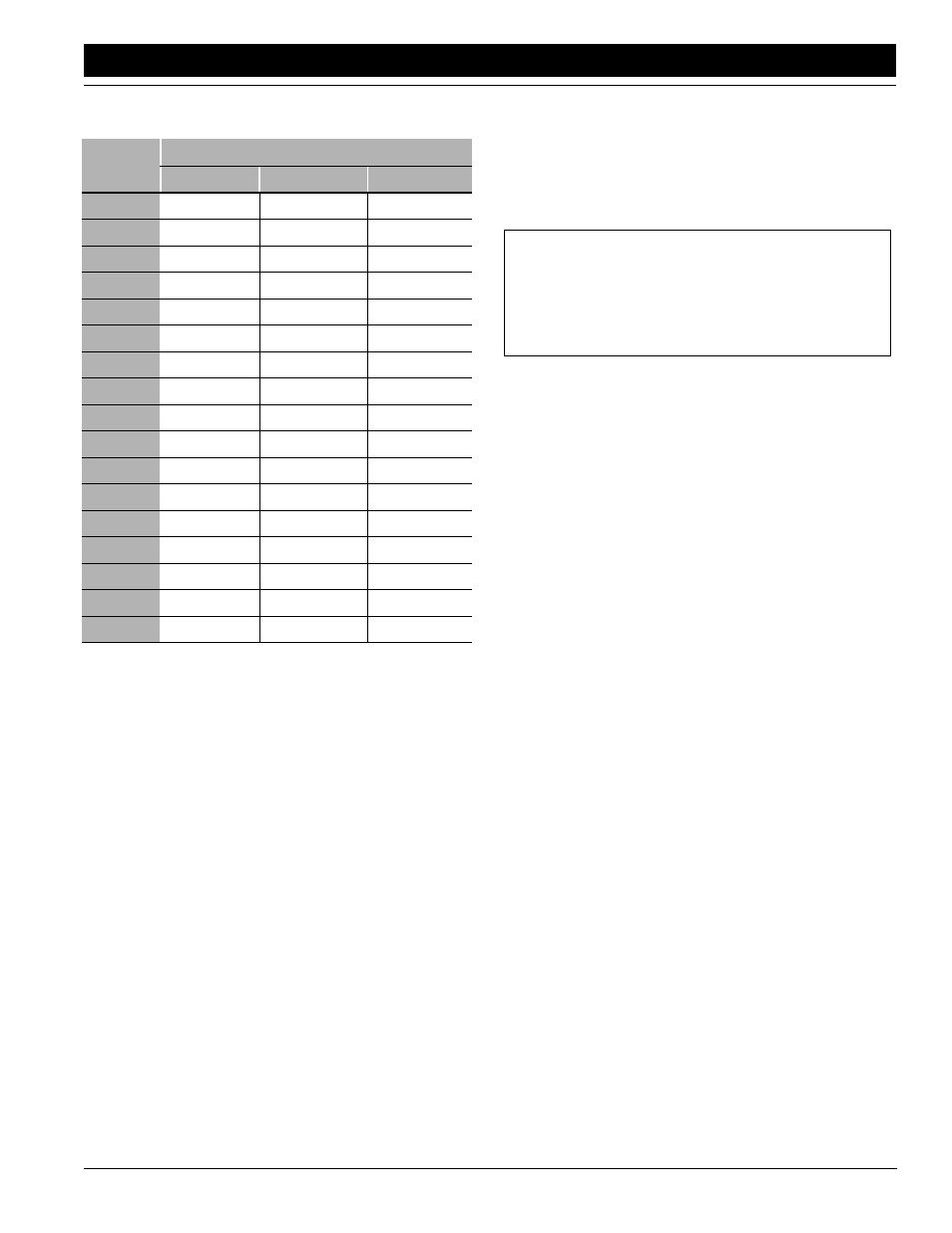

The following chart shows the approximate force at the

openers for a given pressure at the pressure control valve.

NOTE: To account for additional compaction from drill and

tractor tires, set pressure on inside openers slightly higher

than outside openers.

Gauge

Setting

Pounds Force at Opener Disks

6 inch rows

7 1/2 inch rows

10 inch rows

200 PSI

130

135

144

300 PSI

136

144

155

400 PSI

143

152

167

500 PSI

148

160

179

600 PSI

154

167

189

700 PSI

157

172

196

800 PSI

161

178

205

900 PSI

166

184

213

1000 PSI

171

190

223

1100 PSI

172

194

228

1200 PSI

180

203

240

1300 PSI

184

208

248

1400 PSI

189

215

258

1500 PSI

193

220

264

1600 PSI

198

227

274

1700 PSI

202

232

281

1800 PSI

209

240

291