Gang angle adjustment – Great Plains 1500TM Operator Manual User Manual

Page 21

Great Plains Manufacturing, Inc.

Preparation and Setup

17

12/12/2013

586-535M

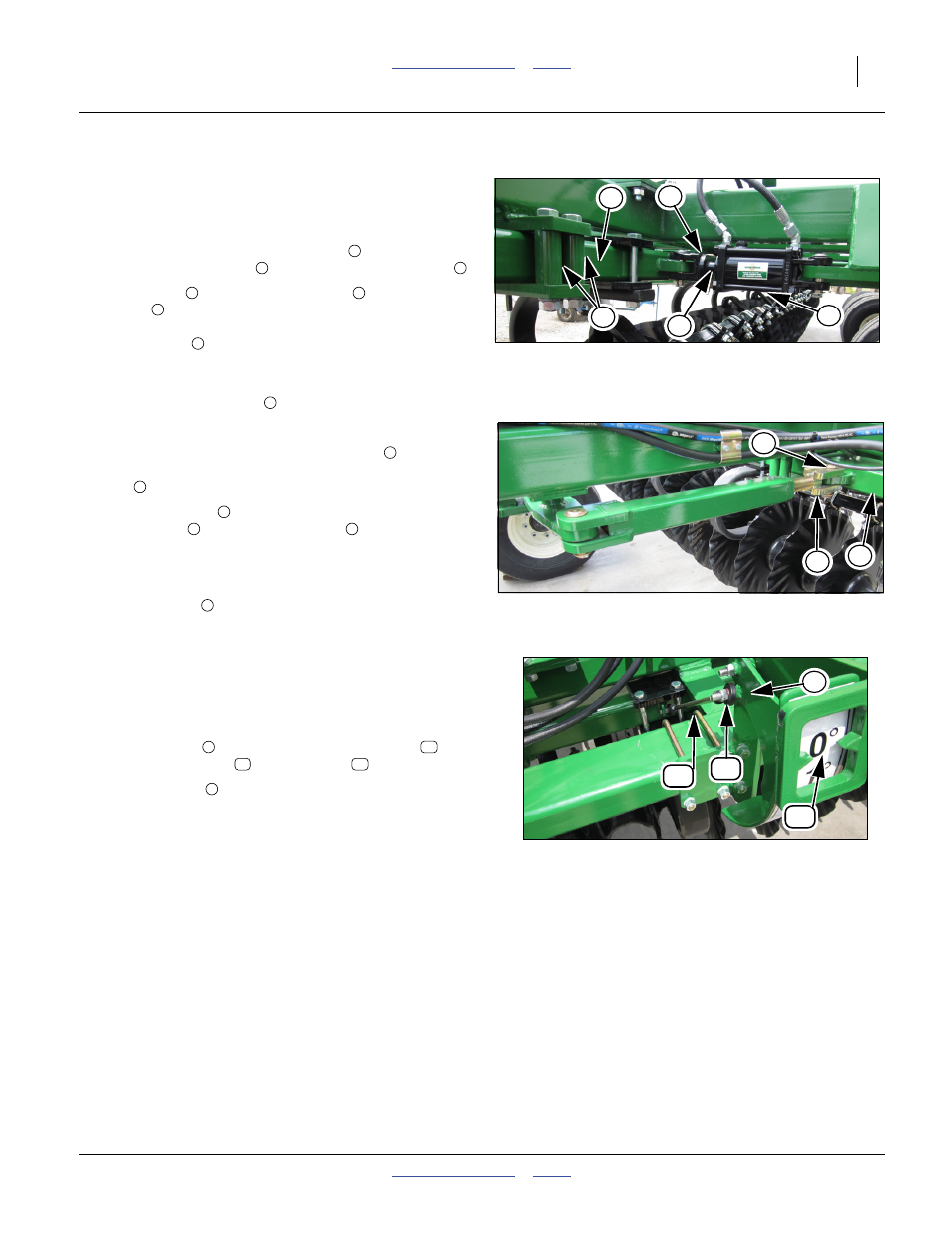

Gang Angle Adjustment

Note: Check gang angle adjustment when machine is new

and annually after, as wear may occur

11. With front gang adjusting cylinders

in the full retract

position the gang bar

should be 1/8” from tubes

.

12. If gang bar

is not 1/8” from tubes

loosen allen

screw

on clevis on rod end of cylinder (there are two

flat spots on rod to get wrench on to adjust) and shorten

cylinder rod

by turning cylinder rod to bring gang bar

closer and lengthen clevis to get cylinder to retract all

the way.

13. Re-tighten allen screw

when adjustment is made.

Refer to Figure 11

14. When the front gang adjusting cylinders

, have been

adjusted and are in the full retract position the rear gang

bar

should be parallel to back frame tube.

15. If rear gang bar

is not parallel to back frame tube,

remove pin

from turnbuckle end

and shorten turn-

buckle end by turning clevis to bring gang bar closer and

lengthen clevis to lengthen to get gang bar to retract all

the way.

16. Re-install pin

when adjustment is made.

17. When the front and rear gangs are adjusted and gang

angle cylinders are fully retracted then the gang angle

indicator will need adjusted.

18. Remove bolt

from either end of gauge link

and

turn threaded end

until indicator

reads 0 degrees.

19. Re-install bolt

to secure gauge link.

Figure 10

Front Gang Angle Adjustment

42251

4

2

3

1

5

1

2

3

2

3

4

5

4

Figure 11

Rear Gang Angle Rocker

42252

7

6

8

1

6

6

7

8

7

Figure 12

Gang Angle Indicator Adjustment

42253

10

11

12

9

9

10

11

12

9