Maintenance and lubrication, Maintenance, Lubrication – Great Plains 2551SC Operator Manual User Manual

Page 22: Wheel bearing hub

540-179M

10/09/2013

18

2536-2551SC

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

Maintenance

1.

Always use the transport lock when working on or

doing maintenance to the seedbed conditioner. If

folded, be sure your wing stop pins are in place.

Read and understand all safety decals on your

equipment.

2.

During the first season of operation check your bolts

for tightness.

3.

Replace or rotate worn parts as needed -- hinge

bolts, clevis pins, bearings, etc.

4.

Check and tighten or replace any hydraulic leaks.

Check hoses for any leaks. It is important that there

are no leaks on the equipment.

5.

Check wheel bearings occasionally for excessive

endplay.

6.

Grease wheel bearings sparingly. Over greasing

may cause damage to seals and reduce the life of

the bearing. Grease hinge points periodically. Reel

Bearings are maintanance free and do not require

greasing.

7.

If machine is stored outdoors over the winter months,

it is a good idea to fold the machine then set it down

on the ground so all the cylinders are retracted to

protect the cylinder rods. This will extend the life of

the cylinder seals and reduce internal and external

leaks.

By following and maintaining a routine service and lubri-

cation program, your tillage equipment will give you

many years of service.

For the most current manual information, visit Great

Plains website listed below. For more information on

operating, adjusting or maintaining your Great

Plains Discovator, assistance is available. Contact:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

(800)255-9215

Lubrication

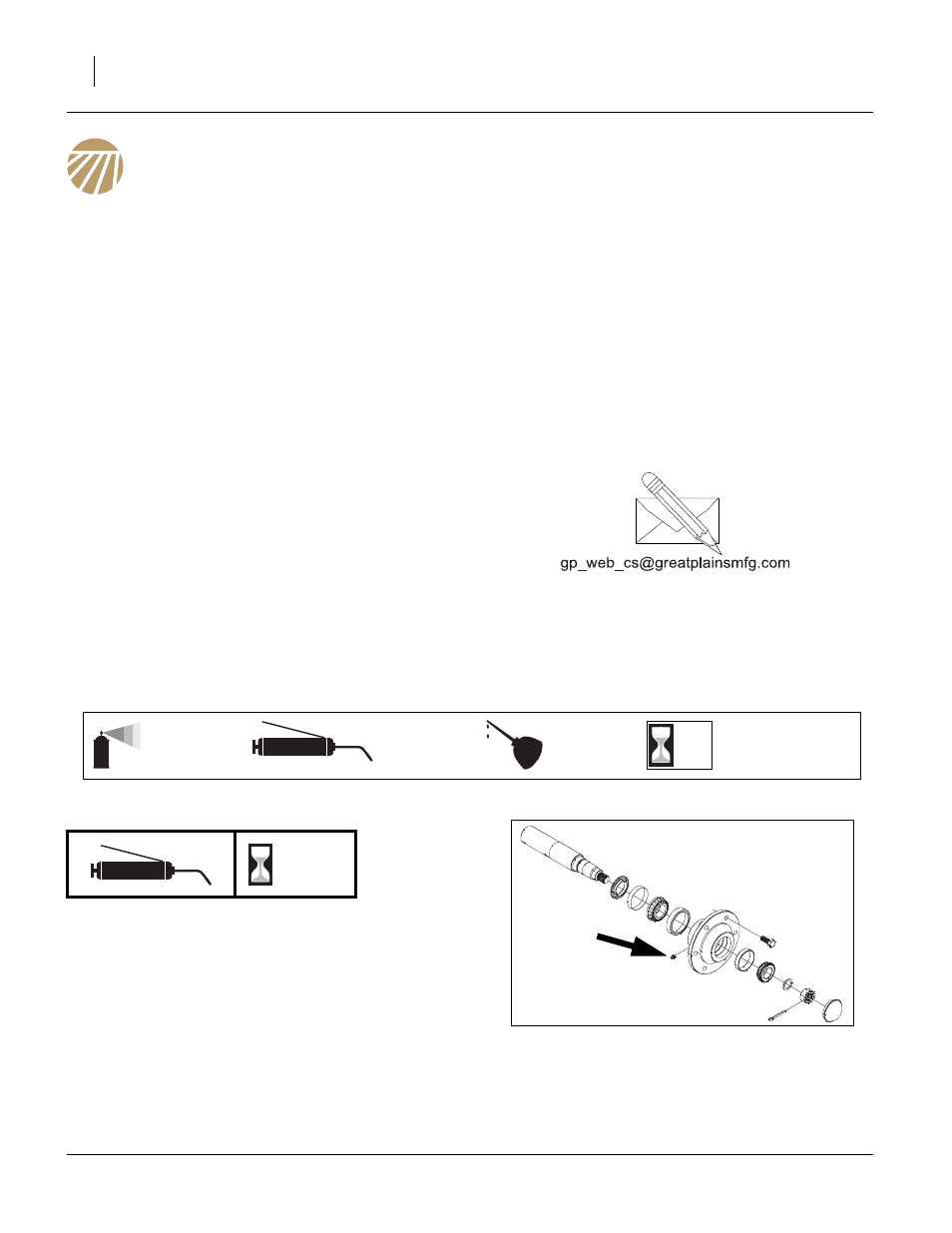

Wheel Bearing Hub

1 zerk on each hub;

2 total

Type of Lubrication: Grease

Quantity: Sparingly, Do Not Over Grease, nay cause damage

seal.

Repack wheel bearings annually or every 2500 acres.

50

50

Multipurpose

spray lube

Multipurpose

grease lube

Multipurpose

oil lube

Intervals (service hours)

at which lubrication is

required

42295