Drive idler adjustment (605nt or 606nt), Seed clean-out, Main box clean-out – Great Plains 606NT Operator Manual User Manual

Page 47

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

43

2014-02-10

151-061M

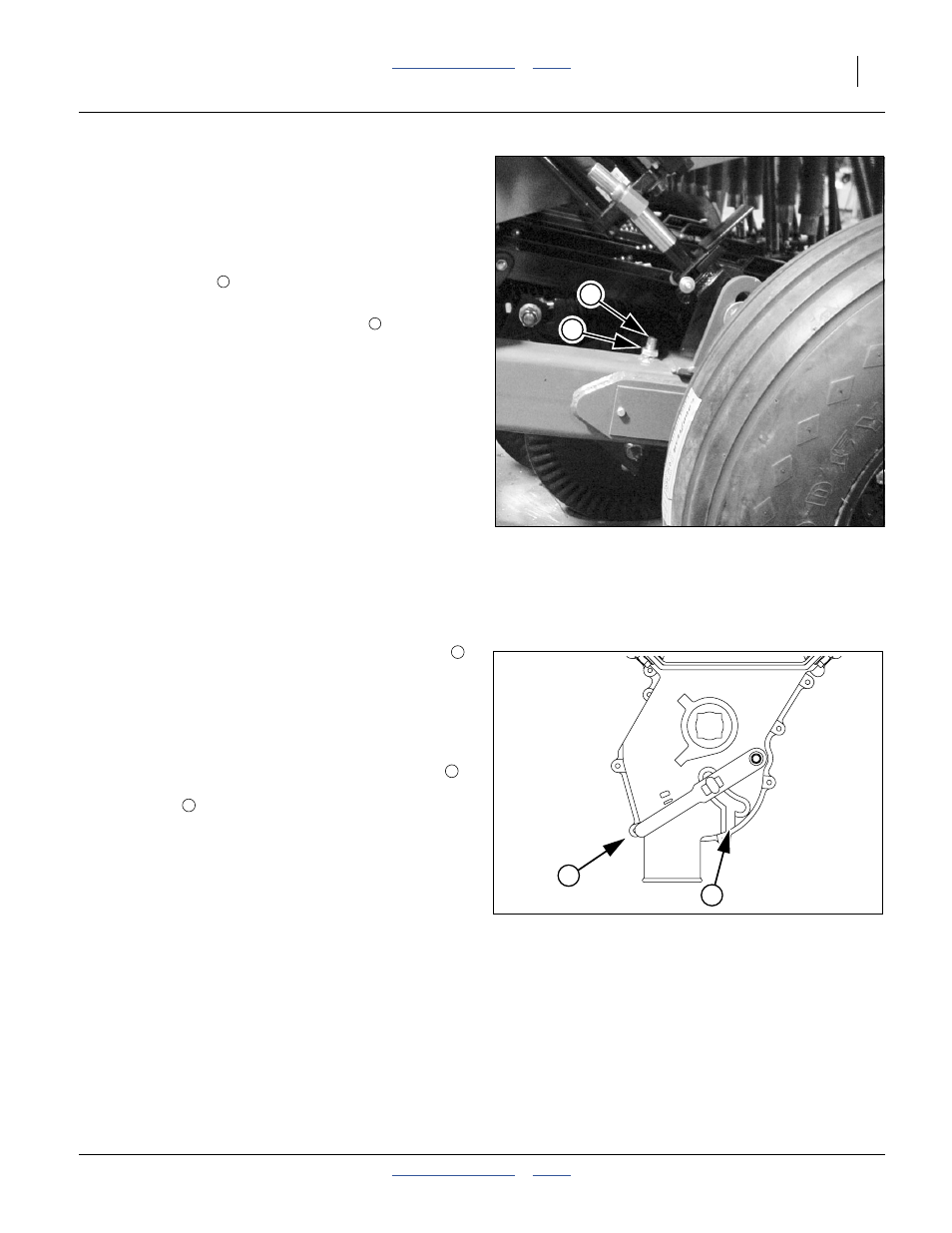

Drive Idler Adjustment (605NT or 606NT)

Two idler sprockets are located inside the left hand

gauge wheel arm. They should be readjusted after the

first 100 acres (40 hectares) of drill use. From then on,

readjust at the beginning of each season.

Refer to Figure 43

1.

Loosen jam nut

.

2.

Move front idler sprocket on top of chain, tightening

chain, by screwing in adjustment stud

.

3.

Retighten jam nut to maintain idler position.

Note: Do not over-tighten stud. Insufficient slack causes

excessive wear and premature chain failure.

Seed Clean-Out

Main Box Clean-Out

Refer to Figure 44, which depicts the seed cup door handle

in a normal operating position

.

1.

Set the Seed Rate Handle to zero (0). This moves

the seed cup sprockets out of the seed path.

2.

Position a tarp or bucket under each row or set of

rows to be cleaned out.

3.

At the seed cup for that row, pull the door handle

out of the operating detent range, and swing it down

to position

.

4.

Open the main seed box and use a small brush to

sweep seed toward seed cups set to clean-out. If

seed does not flow freely, inspect seed cup, hose

and seed tubes for obstructions.

5.

If a vacuum cleaner is available, use it to remove

residual matter.

It is not necessary to operate the seed meter drive shaft

for clean-out. With the Seed Rate set to zero, nothing

moves inside the seed cups; however, an inspection of

the flutes for excess wear and damage does require

shaft rotation.

Set the Seed Rate Handle to 100. Raise and lock-up the

drill. Turn the seed meter jackshaft with the calibration

crank, while another person inspects the flutes from the

open seed boxes.

Figure 43

Gauge Wheel Idler Adjustment

18481

1

2

1

2

Figure 44

Seed Cup Clean-Out

26211

1

2

1

1

2