Height and leveling the drill, Height setup: model 3p605nt or 3p606nt, Adjusting 3-point height – Great Plains 606NT Operator Manual User Manual

Page 21

Great Plains Manufacturing, Inc.

Preparation and Setup

17

2014-02-10

151-061M

Height and Leveling the Drill

Height Setup: Model 3P605NT or 3P606NT

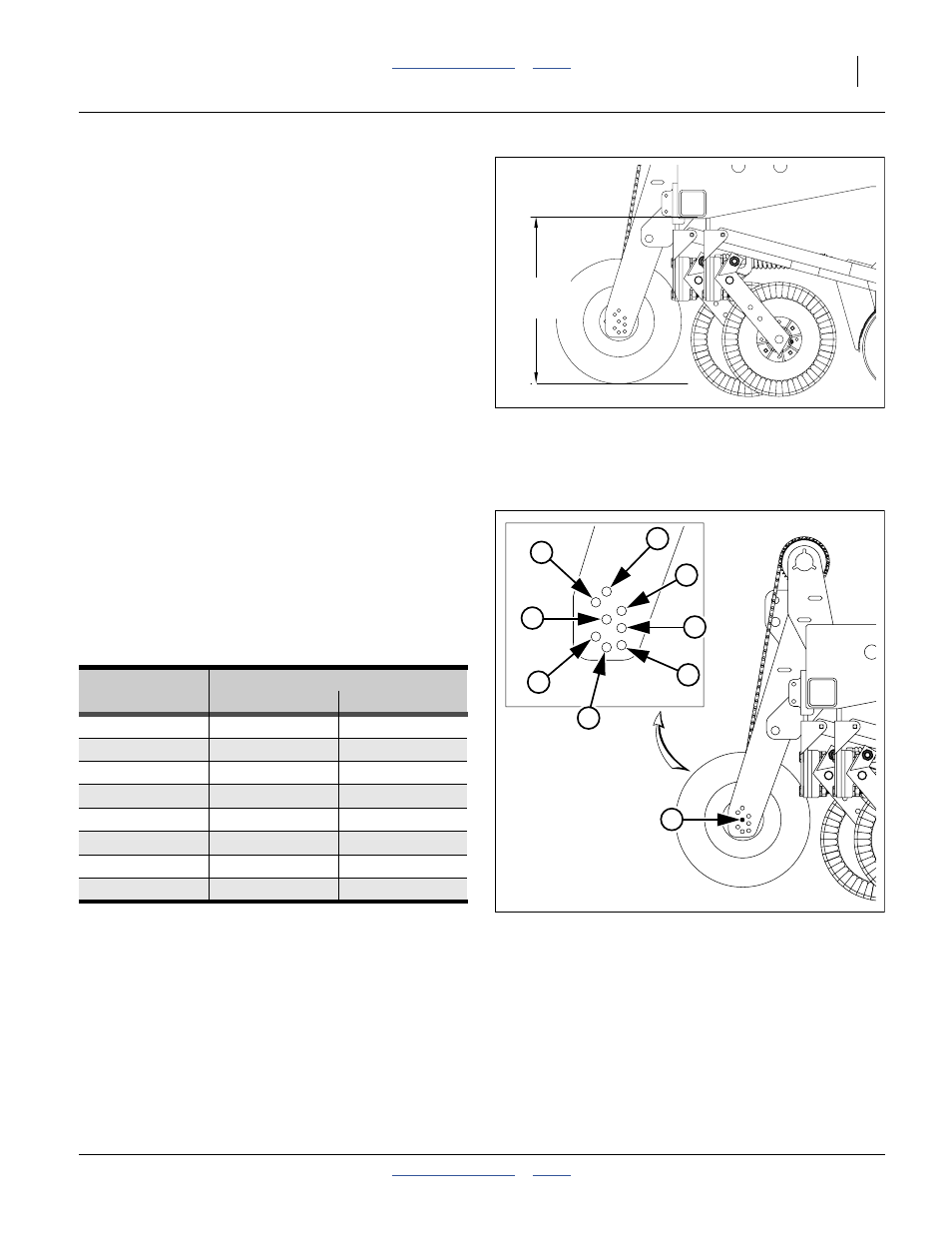

Refer to Figure 9 and Figure 10

1.

Initially adjust drill so opener tool bar runs

24

3

⁄

4

in. (62.9 cm) above ground when drill is

lowered in the field.

2.

The drive wheel should be in the fourth mounting

hole from the top (factory setting).

Note: The drive may need to be adjusted due to ground

conditions.

3.

Level drill with top 3-point link.

Adjusting 3-Point Height

Raising the gauge wheel spindle provides deeper coulter

depth. Lowering the wheel provides shallower depth.

Note: Do not lower coulters to aid in penetrating hard soil.

Instead, increase coulter down-force (page 32).

This may require adding optional weight (page 30).

Refer to Figure 10

1.

Determine new coulter depth desired. With new

discs, the axle holes provide these depths:

2.

Raise drill, unless wheel is already off ground

sufficiently to allow wheel spindle relocation.

3.

Relax chain idlers.

4.

Remove wheel bolts. Move spindle to new hole pair.

Re-install wheel bolts.

5.

Re-engage chain idlers.

Figure 9

Initial Field Height,

3P605NT or 3P606NT

18546

24

3

⁄

4

in.

62.9 cm

Figure 10

Height Adjustment,

3P605NT or 3P606NT

18509

4

1

2

4

6

3

8

7

5

Hole No.

(from top)

Inches

mm

1

3 1/ 2 in.

89 mm

2

2 7/ 8 in.

73 mm

3

2 3/ 8 in.

60 mm

4 (f)

1 7/ 8 in.

48 mm

5

1 3/ 8 in.

35 mm

6

7/ 8 in.

22 mm

7

3/ 8 in.

10 mm

8

1/ 4 in.

6 mm

f. Factory setting.

32774G

Coulter Depth (n)

n. Depth is with new coulter blades.