Great Plains YP4025A-3215 32-Row 15-Inch Quick Start User Manual

Page 3

Quick Setup Guide for IntelliAg Model YP40 30” Twin Row Air Pro

11001-1542-200909

©2009 DICKEY-john Corporation

Specifi cations subject to change without notice.

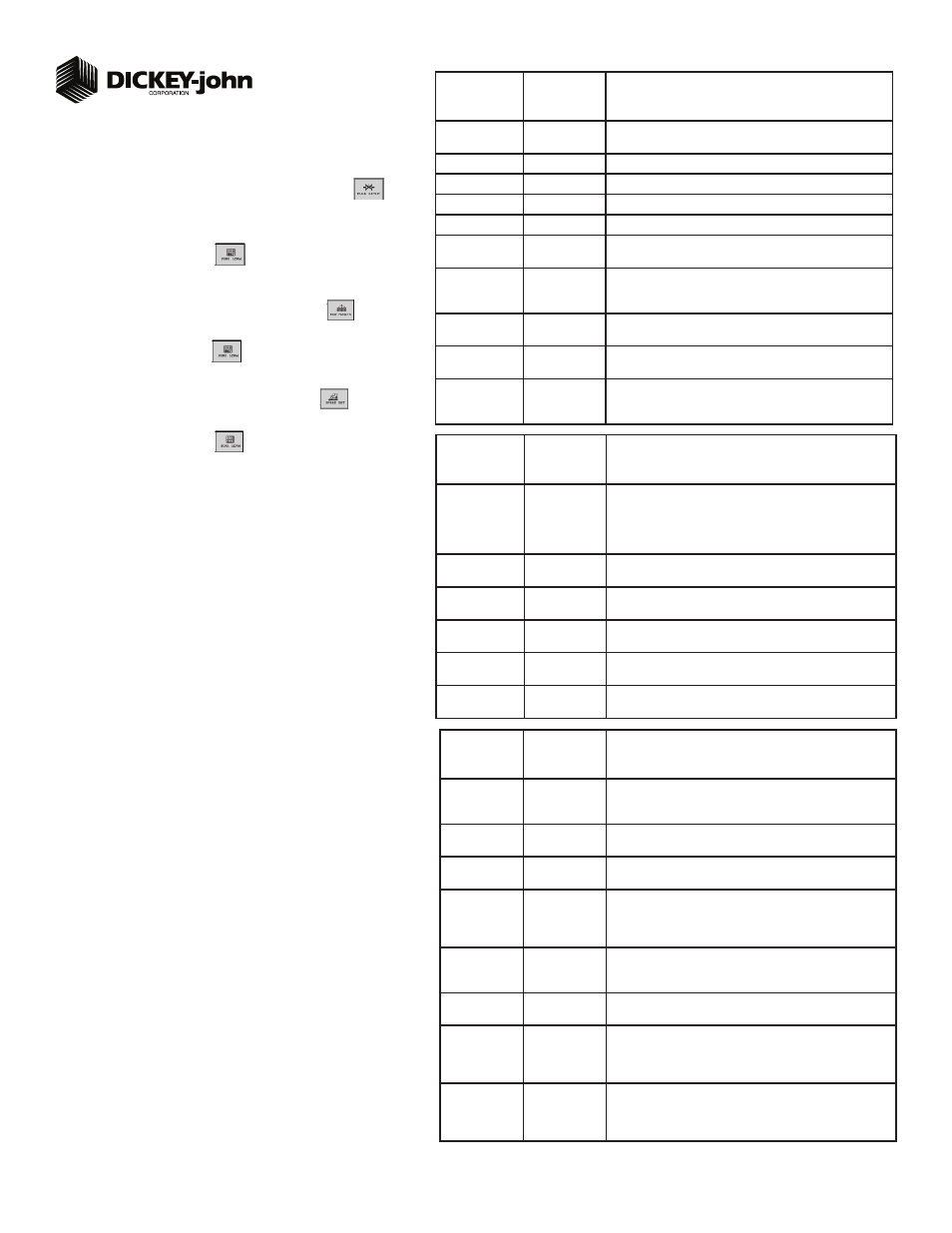

TABLE C2:

Planter Control

Setup

Default Value

or Value to

Enter

Split Air Regulation

Instructions/Defi nitions

Type

Split Air

Regulation

Confi gure Control Channel 2 as Split Air Regulation.

Material Name

Air

Create material name as “Air”.

Control Mode

Auto

Control channel feedback based on air pressure sensor.

Drive Type

Air Reg 2

Automatically selects Air Reg 2 as drive type.

Input Filter

79%

Amount of fi ltering applied to the control channel feedback frequency.

Pressure Drop

0

Difference in pressure sensor mounting location to the seed disk in

inches of H20.

Pressure Slope

447.2269

The change in pressure sensor voltage to a frequency readable by

the IntelliAg system and measured in inches of H20. Should only be

adjusted by qualifi ed personnel.

Pressure Offset

800

Takes a zero point reading that provides a frequency when the fan is

off. Press the Zero Pressure button to calculate frequency.

Planter Selection

YP40

Select Planter Selectin of YP40 to automatically adjust to the ap-

propriate calibration settings.

Sensitivity Adjust

0

Increases or decreases the calibration parameters in the ranges of

-10 to +10. Increasing response time makes the system respond

quicker.

STEP 6B: Planter Control Channel Setup

(Split Air Regulation)

NOTE: Split Air Regulation must be confi gured as Control Channel 2 only.

At the Channel Setup screen, press the Next Channel button

.

At Channel 2 screen, select Split Air Regulation as the Type.

Enter desired values from Table C2.

Press the Work Screen button

to return to the Main Work screen.

1.

2.

3.

4.

TABLE E:

Speed

Set

Default Value

or Value to

Enter

Instructions/Defi nitions

Source

Digital Frequency

Select CAN Ground if radar is connected to ISO tractor cab harness.

Select Digital Frequency if radar or hall-effect is connected to WSMT

actuator harness.

Gspd Constant

12192

Input based on pulse count produced by the ground speed sensor

over 400’ distance. See Operator’s manual for calibration instructions.

Shutoff Speed

0.5 mph

Set desired minimum ground speed allowed before the system shuts

off.

Minimum

Override

2.0 mph

Set to operate when actual ground speed falls below the designated

value. Control will operate at this speed until actual ground speed

rises above minimum override speed or actual speed drops below

shutoff.

Master Sw

Timeout

10

Set to desired number of seconds system shuts off if the master

switch is turned on and there is no ground speed. Toggle master

switch to restart the system and turn off alarm.

Gspd Fail Alarm

Delay

5

Set to desired number of seconds alarm sounds after the ground

speed is zero and seed fl ow continues. (Monitor only)

Precharge

Ground Speed

0

Set to the desired speed the system will use when a precharge time

has been enabled for a control channel. Refer to Table C1: Planter

Control Setup for Precharge Time. This setting will only display when

a Precharge Time has been entered.

Implement Lift

Enabled

Implement lift switch, when enabled, displays an implement lift indica-

tor on the Main Work screen indicating implement lift position as up

or down. Control channels can be turned on and off without using the

master switch.

3

STEP 8: Speed Set Calibration Setup

At the Main Work screen, press the Speed Set button

.

Enter desired values using Table E as reference.

Press the Work Screen button

when ground speed calibration confi gu-

rations are complete to return to the Main Work screen.

1.

2.

3.

STEP 7: Row Monitor Setup

At the Main Work screen, press the Row Monitor button

.

Enter desired values using Table D as reference.

Press the Work Screen button

to return to the Main Work screen.

1.

2.

3.

TABLE D:

Row Monitor

Setup

Default Value

or Value to

Enter

Instructions/Defi nitions

Material Name

See Instructions

Material Name only appears on the Row Monitor Setup screen when

all control channels are disabled and material is set for Monitor Only.

This is only used for ground drive/nonhydraulic applications to monitor

population with high and low alarms. A material must be confi gured

and selected to activate alarms.

High Alarm Delay

5

Desired number of seconds that high population can be above high

alarm point before alarm will sound.

Low Alarm Delay

5

Desired number of seconds that low population can be below low

alarm point before alarm will sound.

Population Adjust

100

Enter a % to allow for seed sensor population inaccuracies to achieve

the desired population display. 100% represents true calculation.

Population Filter

50

Set fi lter value to stabilize the monitored population display. Number

can be set to 0% for no fi ltering and 99% for high level fi ltering.

Row Fail Rate

2/1 (2 seeds

every 1 second)

Set to desired number of seeds per second to trigger seed sensor

failure alarm.