Great Plains YP4025A-3215 32-Row 15-Inch Quick Start User Manual

Page 2

Quick Setup Guide for IntelliAg Model YP40 30” Twin Row Air Pro

11001-1542-200909

©2009 DICKEY-john Corporation

Specifi cations subject to change without notice.

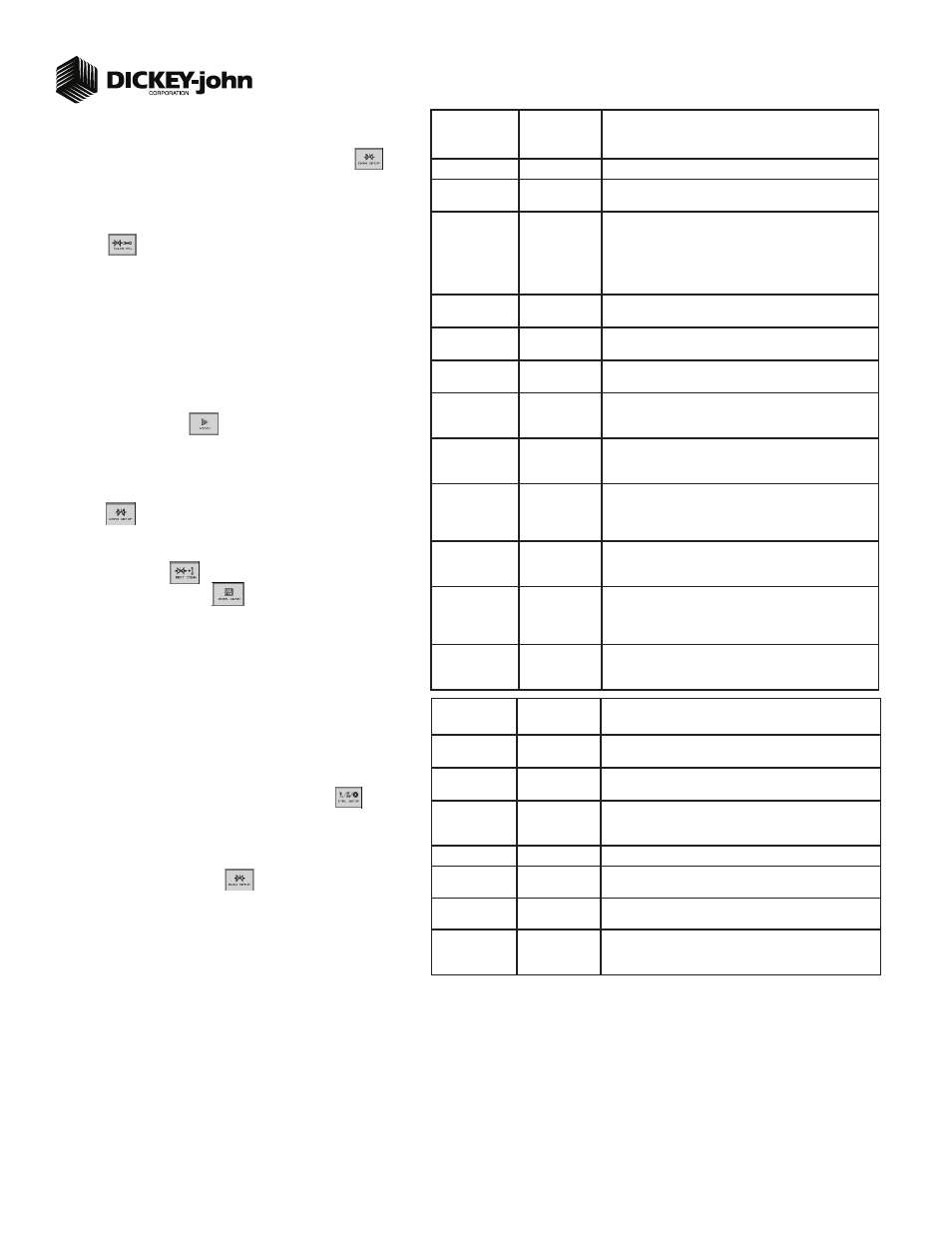

TABLE B2:

Planter Control

Setup

Default Value/

Value to Enter

Instructions/Defi nitions

Type

Planter Control

Set desired Channel Type as Planter Control.

Material Name

Displays only materials that have been confi gured for the channel

type.

Control Mode

AUTO

Auto is used in normal operating conditions calculating the rate

of how the system is running. Manual mode acts as an override

if application rate sensors are inoperable allowing the use of

increase/decrease buttons to set the fl ow rate for the control.

Refer to System Confi guration section of Operator’s manual for

additional information.

Drive Type

PWM

A hydraulic valve varies the oil fl ow to the motor proportioned to

the electric current supplied.

Drive Frequency

100 Hz

If not using a DICKEY-john supplied valve, see the manufacturer’s

specifi cations for drive frequency.

Input Filter

50

Feedback frequency fi lter for the control channel. DO NOT

CHANGE.

Gear Ratio

1.900

Specifys the actual ratio from the feedback sensor to the seed

meter shaft RPM. Number of revolutions the feedback sensor

turns in relation to one revolution the seed meter turns.

Sensor Constant

360

Sensor Constant establishes the number of pulses for one revolu-

tion of the feedback sensor. If a DICKEY-john application rate

sensor is used, the value should be set to 360.0.

# of Seed Rows

32

Entry of a specifi c number of seed rows for the control channel.

Row assignment is given a priority based on the channel and will

be assigned sequentially thereafter. Channel 1 is always assigned

to the fi rst set of rows, Channel 2 next set of rows, and so on.

Channel Width

480

Manual entry of the channel width for rows assigned to a specifi c

channel. Width calculation can be determined by # of planter rows

assigned to the channel multipled by the row spacing.

Precharge Time

+ 0.0

Typically used during startup conditions in the fi eld, a Precharge

time is a specifi ed length of time a control channel will operate

at the defi ned Precharge Ground Speed. Must be entered as a

positive (+) number.

Delay Time

- 0.0

Length of time before the control channel will start after the master

switch has been turned ON and the implement switch is in a

lowered position. Must be entered as a negative (-) number.

STEP 5B: Planter Control Channel Setup

(Controlled Hydraulic Drive)

At the Control Setup screen, press the Channel Setup button

.

Select Channel 1 and verify that the channel is set to Planter Control.

Enter desired values using Table B2 as reference.

After planter control setup, calibrate hydraulic valve by pressing the Valve Cal

button

.

Ensure implement is raised. With brakes locked and transmission in PARK

position, start engine.

Engage hydraulics and run engine at normal speed until hydraulic fl uid is at

operating temperature.

Verify point row clutches are turned ON.

Do NOT perform this step unless meters are installed in all locations

across planter row units or drive damage will occur.

Press the START button

. Turn the master switch to the ON position.

The valve calibration will immediately start. Keep the hydraulics engaged until

the calibration completes.

When the screen indicates calibration is complete, press the Channel Setup

button

to return to Channel 1 home screen.

Turn the master switch OFF.

To set up additional control channels (planter or fertilizer control), press the

Next Channel button

.

Press the Work Screen button

when channel confi gurations are

complete to return to the Main Work screen.

Once a control channel has been established as Planter Control, any new materi-

als established as Planter Control on the Material Setup screen will automatically

be added as optional materials for Planter Control channels on the Control Setup

screen.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

2

STEP 6A: Material Confi guration Setup (Split Air Regulation)

It is recommended that when setting a control channel for split air, the

material name be created as “Air” to eliminate confusion between the actual

material and the control used.

At the Main Work screen, press the Control Setup button

.

Press Material button 16 for Split Air Control

Create Material Name as “Air”.

Enter desired values from Table C1.

Press the Channel Setup button

to proceed to the Channel Setup

screen.

1.

2.

3.

4.

5.

TABLE C1:

Material Setup

Default Value/

Value to Enter

Split Air Regulation

Instructions/Defi nitions

Type

Split Air Reg

Desired type of application control channel being used for a specifi c

material. CREATE MATERIAL NAME AS “AIR”.

Units

In H20

Oz in2

Automatically changes with the type of material application

selected. Changes units for target application.

Preset Method

Disabled

User-defi ned target rates can be confi gured and when enabled can

be adjusted from the Main Work screen using the Increment/Decre-

ment buttons.

Target Rate

2.00

Establishes the desired rate of application in inches of H20.

Max Rate

5.00

Maximum application rate in inches of H20.

Min Rate

1.00

Minimum application rate in inches of H20.

Inc/Dec %

5%

Percentage of change of the entered target rate applied each time

the Increment/Decrement button is pressed on the Main Work

screen.