Figure 8 emerging grease at coulter, Periodic lubrication, Parts list – Great Plains 3P605NT Assembly Instructions User Manual

Page 4: 124a 6’ grease bank field kit

Great Plains Mfg., Inc.

4

Grease Bank

151-125M

09/25/2006

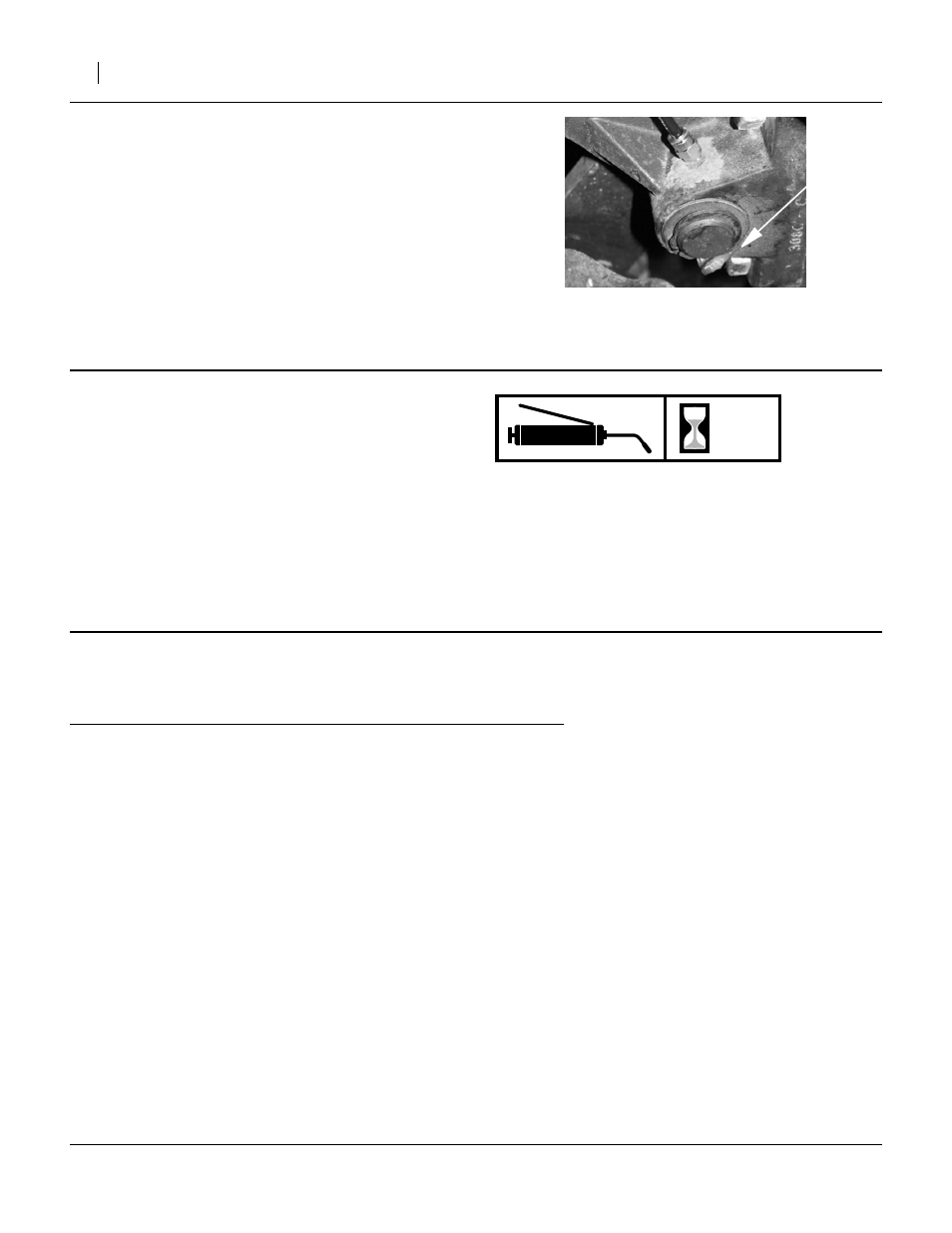

12. Fill each position with grease, checking for leaks.

Add grease until excess grease appears at the

coulter bearing.

Figure 8

Emerging Grease at Coulter

Periodic Lubrication

This section covers general operating procedures once

the Grease Bank kit is installed and filled with grease.

1.

Ensure that the drill is immobilized, either:

• parked, blocked and lowered, or

• securely hitched to a tractor that is shut off (key re-

moved) and has its parking brake engaged.

2.

Inspect grease tubing for damage and leaks.

3.

Have a suitable grease & grease gun at hand.

4.

Clean grease bank zerks of debris.

Coulter Bearings

9 zerks per drill

(at grease bank if installed)

Type of lubricant: Grease

Quantity: until grease emerges

Parts List

151-124A 6’ Grease Bank Field Kit

Your kit includes:

Great Plains Manufacturing, Inc.

Corporate Office: PO Box 5060

Salina, KS 67402-5060 USA

25100

8

Ref. Qty.

Part No.

Part Description

1

151-125M

This document

➀

1

151-259D

6’ GREASE BANK MOUNT (Arm)

➁

1

149-553D

GREASE BANK (Plate)

➂

9

800-130C

ZERK GREASE STRAIGHT 1/8-27

➃

12

800-303C

CABLE TIE 2 MIN - BLACK

➄

9

800-158C

FTG. TUBE, CONNECTOR 1/8 FNPT

➅

2

802-014C

HHCS 3/8-16 NYLON INSERT

➆

2

803-078C

NUT LOCK 3/8-16 NYLON INSERT

➇

42’

990-109R

TUBE NYLON 1/4 OD X 062 WL

➈

9

800-211C

GREASE ADAPT 1/4-28M X 1/4TB

➉

1

802-091C

HHCS 1/2-13 X 1 1/2