Figure 16 – Great Plains 2SNG30 Material Rate User Manual

Page 21

Great Plains Manufacturing, Inc.

Native Grass Planting

19

12/01/2010

202-578B

14. Divide desired rate of pounds per acre by the pounds

per shaft revolution (this is the number obtained from

step 13). Find this number (or the closest number to

this) in the drive setting chart. This will give Drive

Type and Native Grass sprocket sizes.

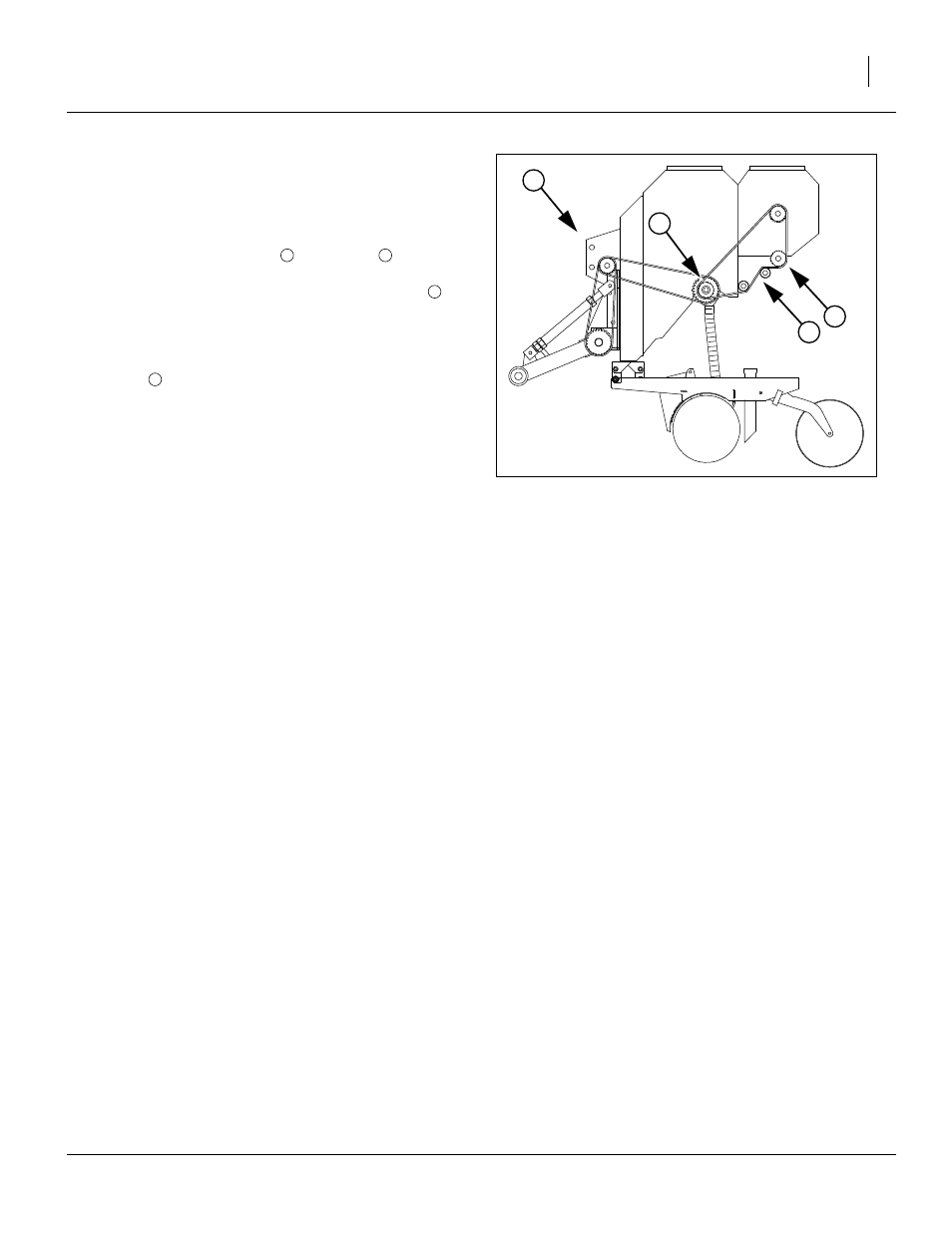

15. Determine which Driving

and Driven

sprockets

and Drive Type are required for the native grass box.

The sprockets are stored on the left-hand side

the drill frame. The drive type is set by ground drive

sprockets (see page 3).

To change Native Grass sprockets, loosen the chain

idlers

and remove chain.

Replace with desired sprockets.

You may want to repeat the calibration procedure if your

results vary greatly from the seed rate chart.

Note: All native grass mixes will vary in weight, seed type,

and density, so this is why you must calibrate each

mix.

Note: It is necessary to calibrate seed mix before set-

ting seed rate.

16. Set the other wing to match the wing now calibrated.

17. Re-attach the seed tubes on the tested rows. Return

the calibration crank to the storage stob of the wing

customarily used for calibration.

Note: When drilling, check the amount of seed you are

using by noting acres drilled, amount of seed add-

ed to drill, and level of seed in drill box. If you sus-

pect that you are drilling more or less than desired,

and you have accurately calibrated the drill to your

seed, you may need to adjust the seeding rate

slightly to compensate for your field conditions.

Figure 16

Native Grass Drive

26294

3

4

2

1

DRIVING

DRIVEN