Great Plains 2SNG30 Material Rate User Manual

Page 16

14

2SNG24 & 2SNG30

Great Plains Manufacturing, Inc.

202-578B

12/01/2010

8.

Rotate gauge wheel or calibration crank one acre, as

tallied on Acremeter, or as counted based on values

from table below.

Note: These settings are based on 9.5L-15 tires inflated

to factory specifications.

9.

Check that the three seed cups have plenty of seed

coming into them.

10. Weight metered seed. Subtract initial weight of con-

tainer. Divide by three.

11. Multiply by the number of openers on the drill to

determine total pounds seeded per acre. If this figure

is different than desired, change your sprockets and

drive type accordingly.

Note: If your results vary greatly from seed rate chart,

apply the revised Drive Type and Seed Rate

Handle settings, and repeat the calibration pro-

cedure.

12. Set the other wing to match the wing now calibrated.

13. Re-attach the seed tubes on the tested rows. Return

the calibration crank to the storage stob of the wing

customarily used for calibration.

Note: When drilling, check the amount of seed you are

using by noting acres drilled, amount of seed add-

ed to drill, and level of seed in drill box. If you sus-

pect that you are drilling more or less than desired,

and you have accurately calibrated the drill to your

seed, you may need to adjust the seeding rate

slightly to compensate for your field conditions.

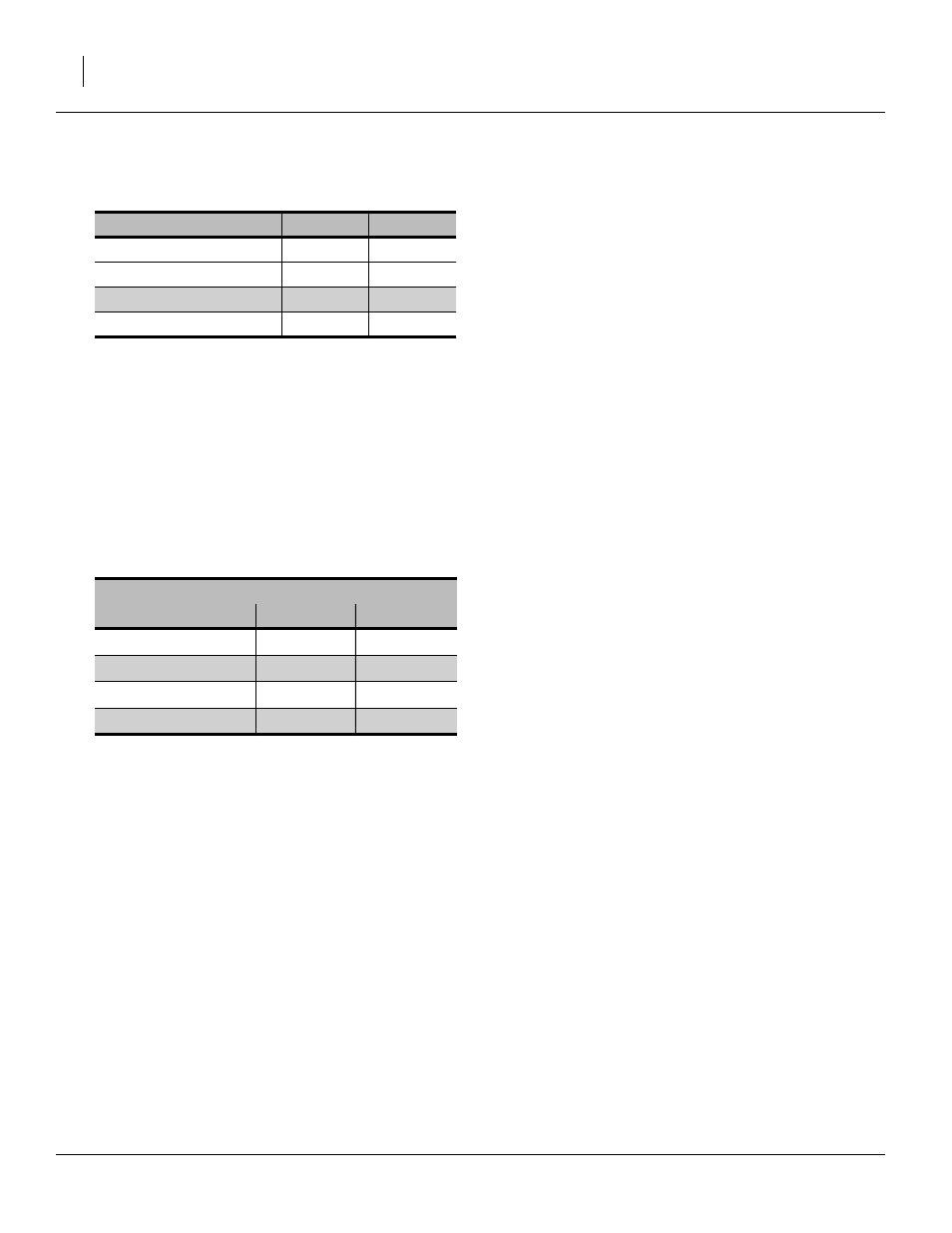

Revolutions for One Acre

2SNG24

2SNG30

Crank: Drive Type 1

151

122.5

Crank: Drive Type 2

44.5

40

Crank: Drive Type 2A

101.5

82

Gauge Wheel

225

182

Total Row Units

Model

Spacing

Rows

2SNG24-2810

10 inch

28

2SNG24-3875

7.5 inch

38

2SNG30-3610

10 inch

36

2SNG30-4875

7.5 inch

48

MeasuredSeed

EmptyContainer

–

3

-------------------------------------------------------------------------------------------

PoundsPerSeedCup

=

undsPerSeedCup

NumberOfOpeners

×

PoundsPerAc

=