Great Plains EWF13 Assembly Instructions User Manual

General information, Assembly instructions, Sprocket box update

1

Update Instructions

Great Plains Mfg., Inc.

© Copyright 1998 Printed 2/24/98

Used with:

•

152-208M

EWD13 and EWF13

Sprocket Box Update

13-Foot, End-Wheel Drills

General Information

These instructions explain how to install and adjust the sprocket-

box update. The sprocket box replaces the original gearbox on

Great Plains end-wheel drills. This modification improves the

performance and reliability of the original equipment.

These instructions apply to

152-207A

13-Foot EW Sprocket Box Update Kit

Manual Update

Pages 4 and 5 of these instructions cover how to adjust the seed-

ing rate with the new sprocket box. These instructions replace

the "Clutch Shaft and Miter Gear Alignment" and "Seed Calibra-

tion" sections in the operator’s manual originally provided with

your drill. As reference, save pages 3 and 4 of these instructions

with your operator’s manual. A copy of the updated parts manual

is available through your Great Plains dealer.

Refer to the drill operator’s manual for detailed information on

safely operating, adjusting, troubleshooting and maintaining the

drill. Refer to the drill parts manual for part identification.

•

13-Foot End Wheel Drill Operator’s Manual . . . . . . . . . . . . . . . . . . . 175-083M

•

13-Foot End Wheel Drill Parts Manual . . . . . . . . . . . . . . . . . . . . . . . 175-083P

Before You Start

Page 6 is a detailed listing of parts included in the sprocket-box-

update kit. Use this list to inventory parts received.

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life and

the lives of others depend on it!

!

Assembly Instructions

Disassembling the Gearbox

1.

Remove end-wheel-output and gearbox-output chains.

2.

If your drill has 7-, 8- or 10-inch row spacings, you must in-

stall a new opener-lift arm and remove the existing arm. If

your drill has 6- or 7.5-inch row spacings, proceed to step 3.

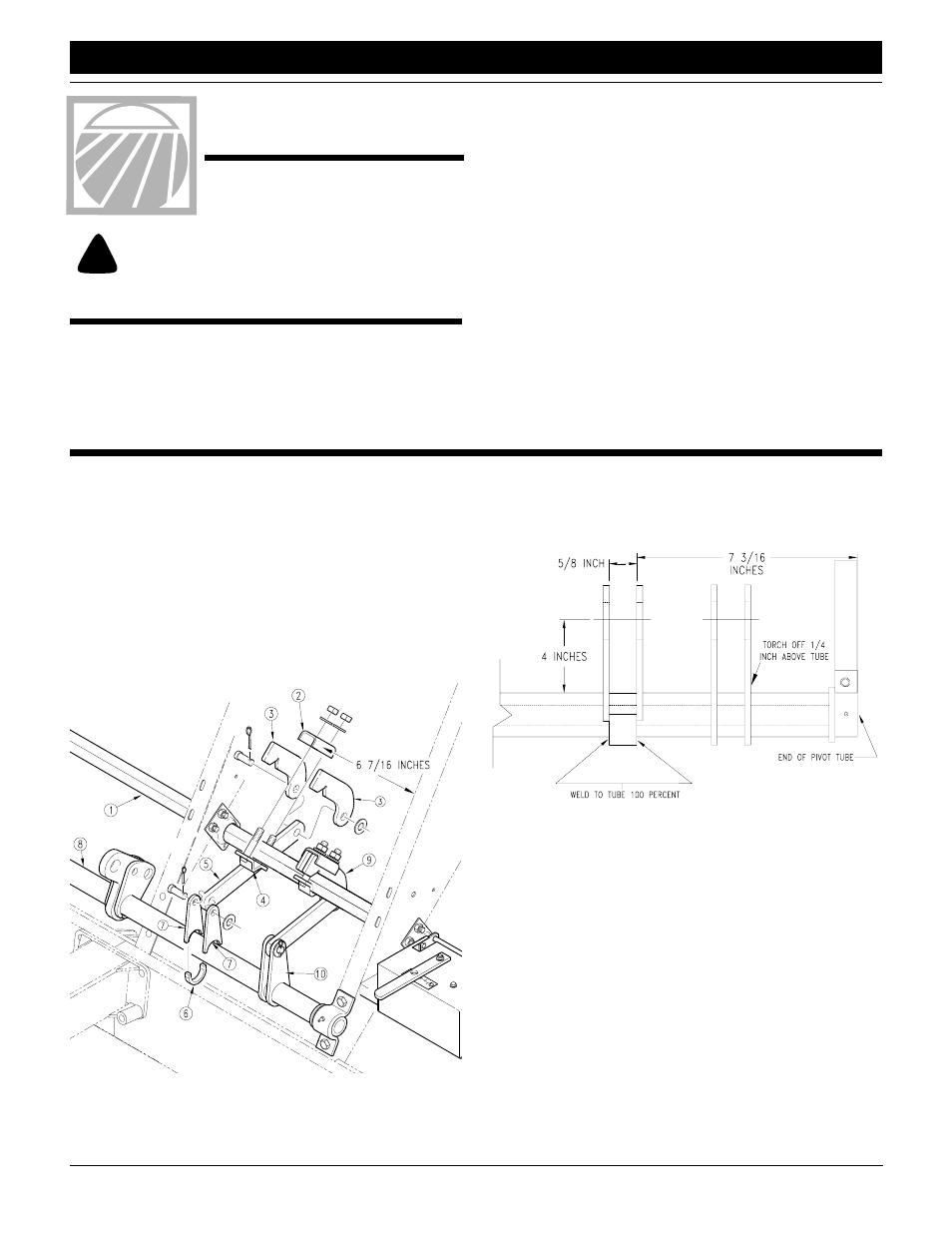

To reposition the opener-lift arm, refer to Figure 1-1.

a.

Assemble the clamp on the square opener shaft (1).

Place the channel bracket (2) over the link arms (3). Po-

sition the clamp 6 7/16 inches from the frame plate. Se-

cure to shaft with the mounting strap (4), 5/8-inch

washers and bolts.

b.

Using a 3/4-inch clevis and cotter pin, pin the link arm

(5) to the newly installed clamp.

16597

Figure 1-1

Opener Lift Arm

c.

Weld the mount collar (6) and double ears (7) on the

pivot tube (8) so you can pin the link arm to the ears.

Use the link arm as a guide to properly position the col-

lar and ears on the tube. Refer to Figure 1-2 for general

dimensions.

16598

Figure 1-2

Weld and Torch Diagram

d.

Pin the link arm to the double ears using the 3/4-inch

clevis and cotter pins.

e.

Remove existing opener-lift arm (9) by torching off the

double ears (10). Cut the ears 1/4 inch above the pivot

tube. Disassemble the existing opener-shaft clamp.

Discard all disassembled parts.

f.

Spray paint the pivot tube with the paint provided. Thor-

oughly cover the welds and any paint damage.