Monarch Instrument SPLS-5 Series User Manual

Page 7

4

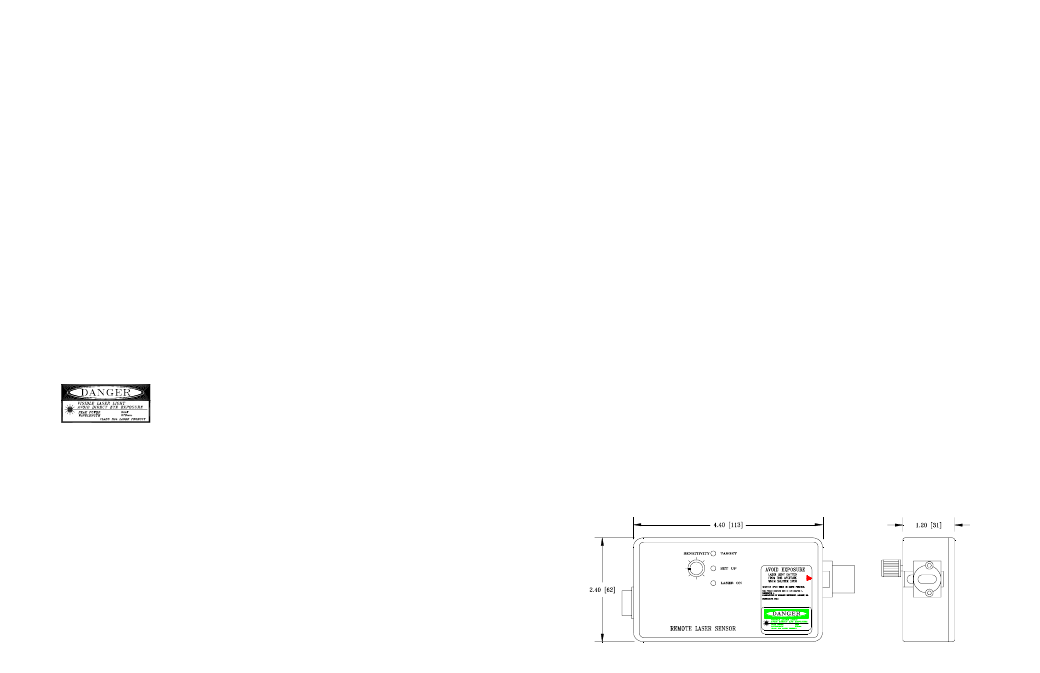

RLS-5P Remote Laser Sensor

Laser:

Visible red laser diode (670 nM), 5 mW peak power

Excitation Voltage: 4.8 to 8 Vdc @ 75 mA

Classification:

Normal Mode:

Class IIIa Laser Product

Setup Mode:

Class II Laser Product

Beam Divergence: 1.5 mrad typical

Beam Diameter:

4 x 0.6 mm

Laser Diode Life: 100,000 hours typical

Operating Range: Up to 50 feet [15 m] with reflective target

Min. Trigger Duration: 50 usec (equiv to 250,000 RPM)

Output:

5 to 0 Vdc TTL compatible pulse (open collector with

4.7 k pull up to 5 Vdc)

Connector:

Circular DIN Mak 4100 Socket

Indicators:

LASER ON, SET UP and ON-TARGET LEDs

Sensitivity Adjust: Single turn trimmer control knob on top panel

Modes:

Normal: Adjust sensitivity and distance from target

Set Up: Set up for reduced power (factory preset)

Dimensions:

Length: 5.5" [141 mm] including laser nosepiece

Body:

4.4" x 2.4" x 1.2" [113 mm x 62 mm x 31 mm]

Weight:

10 oz. [283 grams]

Mounting:

¼ -20 UNC Bushing in base of housing for tripod mount

or customer supplied bracket (can also be used to ground

the Remote Laser Sensor)

Temperature: Operating: -5

°

F to 122

°

F [-20° C to +50

°

C ]

Storage:

-25

°

F to 140

°

F [-30° C to +60

°

C ]

Humidity:

90% RH non-condensing

Controls

The Laser Sensor can detect small changes in reflective light due

to color or contrast changes, holes or slots in the surface or

reflectivity of the subject. The actual sensing distance varies, and

may be adjusted using the “Sensitivity” adjustment control on the

Laser Sensor. For maximum distance, it is advisable to use areas

of high contrast or reflective tape on the rotating object.

Operating the SPLS-5 as a triggering source

Mount the RLS-5P securely on a tripod or fixed surface that can be

moved for alignment purposes. For ease of alignment and reliability of

operation, locate the sensor as close to the target as practical (but not

within one inch). It is recommended that you aim the sensor at a

slight angle from perpendicular (approximately 15 degrees) to

ensure the sensor will detect only reflected pulses.

Turn the “Power” switch on the SPS-IM module to the ON position.

Open the shutter on the Laser Sensor. Observe that the LASER ON

LED illuminates.

CAUTION:

Avoid direct eye exposure to the laser beam.

Visually align the laser light with the target, ideally with the moving

equipment stopped. Start the equipment, and further adjust the manual

alignment and the “Sensitivity” control to maximize the brightness of

the green “TARGET” LED. This will be the condition of

optimum performance.

The pulse signal on the connector marked “Output” provides a sharp

leading edge for reliable and repeatable triggering of the connected

device. This output has a low impedance (50 ohms) and is capable of

11