Air tube disc clutches and brakes, Application guidelines application factors – Wichita Clutch LK Brake User Manual

Page 2

B

Air Tube Disc Clutches and Brakes

P-1100-WC 1/12

Wichita Clutch 800-964-3262 23

where this is not pos si ble, forced air

cooling may be nec es sary for

extended clutch life.

6. Safe clutch operating speeds should

be maintained in product design.

Maximum Clutch Contact Velocity

FPM Material

6,000

(Recommended

cast iron

9,000

upper limit for slip)

ductile iron

12,000 steel

Dynamic balancing recommended when

peripheral speeds exceed 3500 FPM.

The maximum speeds shown are safe

op er at ing speeds based on years of

Wichita testing. Please do not exceed

these limits.

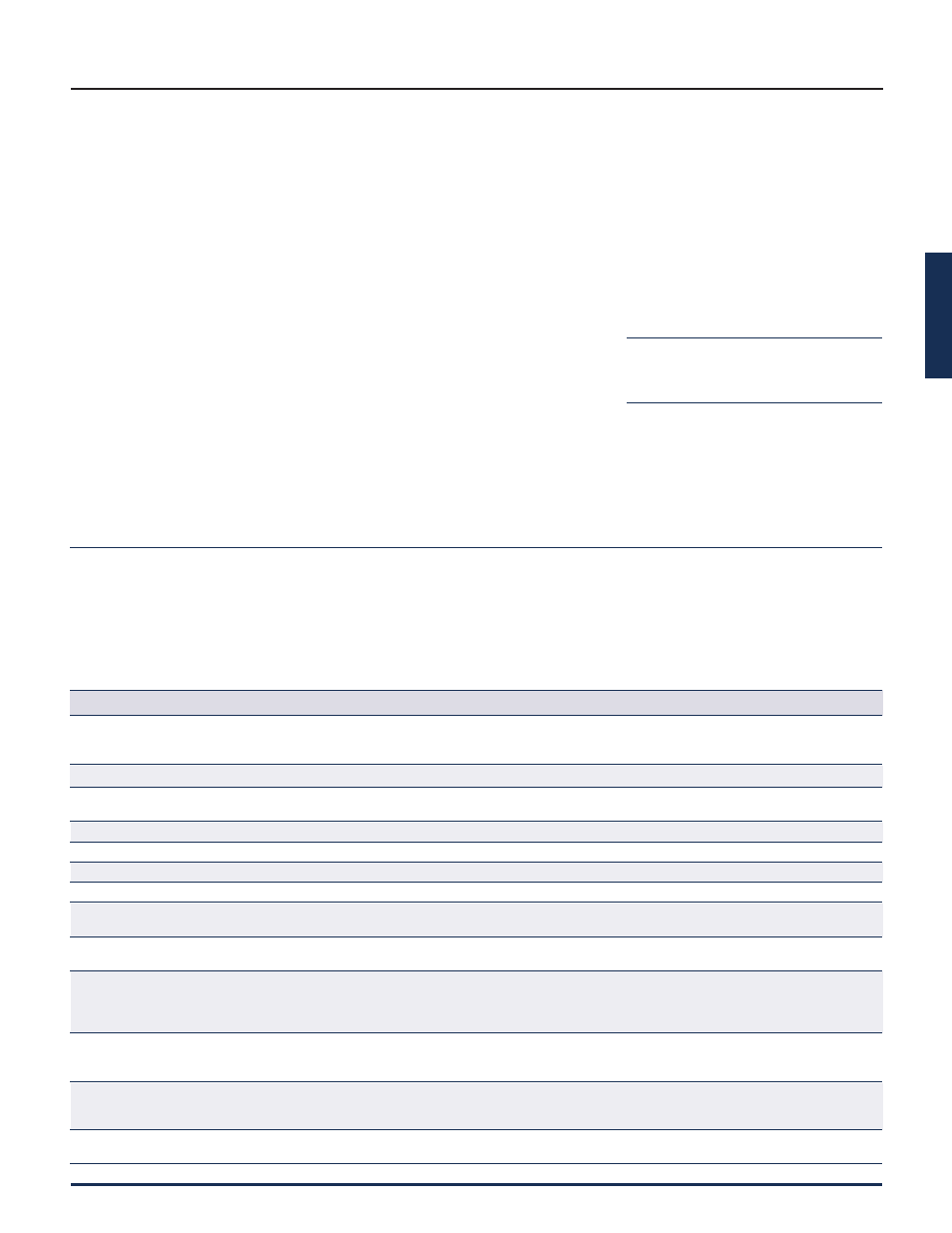

Field of Application Group A Group B Group C Group D

Pumps Centrifugal Reciprocating compressors Reciprocating compressors

compressors over 2 cylinders, one or two cylinders

centrifugal fans & blowers

Agitators Liquid Semi-solid Solids

Brick Brick press, extruder, pug mill

manufacturing

Canning & bottling machine Bottle-can feeders, filling, mixers

Engine driven equipment Crane, hoist, engine Crowd

Grinding mills Ball-rod-sag-pebble Crushers, shakers

Lumber processing Yarder Carriages, conveyers Chipper, logger

Marine Propulsion clutch CP wheel Shaft brakes, propulsion

reversing type, anchor winch

Bulk material Conveyors evenly loaded, Feeders Elevators

handling line shaft evenly loaded

Metal production & Coilers, slitters, press brake, Draw bench, rolling mill, Hammer mill, forming

metalforming non-geared press, geared press shear, back geared press, press, forging press,

deep draw press, transfer header press, knuckle press

press, toggle press

Paper industry dryer Fourdrinier to 500 FPM, Fourdrinier to 1800 RPM

sections & calenders paper mill plane & press selections, calenders

Consult factory smoothing press & dryers

Petroleum Drilling & service rig master Mud pumps,

production clutches, compound clutches, PTO clutches

rotary, drum

Rubber Transfer machines Banberry mixer, drum mixer, Centrifuge

manufacturing evenly loaded extruder, calender

This chart gives application factors

ranging from light duty (the A group) to

extra heavy duty (the D group).

After initial usage is determined, see

Clutch sizes are affected by the

following variables:

1. Machines that operate under smooth

loads require smaller clutches. These

machines are driven by either

multi-cylinder high speed engines or

electric motors with reduced starting

current.

2. Drives that require high starting

current motors will require clutches

with sufficient torque to prevent

excessive slipping while starting.

3. Starting torque may be high, which

requires a fast clutch response time

to transmit the required torque; or,

extended clutch slip time is required

to protect the prime mover.

“Selection Requirements” to com plete

the selection process. The in fla tion and

exhaust time should also be checked to

insure proper response.

4. Starting torques may be very low

compared to the normal torque,

which may result in the clutch not

being fully pressurized prior to the

time of full torque requirement. This

will cause the clutch to overheat from

slippage. Clutch inflation time in this

instance is very important.

5. Clutches on most machines are

designed to slip prior to damage

from shockloads. As a result, the

clutch may require periodic

main te nance; therefore, the clutch

should be located for easy access in

the power train.

Clutch es should also be located for

max i mum cooling air. In instances

Application Guidelines

Application Factors