Specifications – ORBIT FR Hybrid Clean Room Absorbers User Manual

Page 2

The hybrid clean room absorbers are coated in clear latex top and bottom for use in class

100,000 clean room environments. The overall performance is unaffected by this treatment. These

absorbers are used extensively in satellite assembly facilities as well as other aerospace

applications.

Ferrite Hybrid

Technology

Ferrite absorbers offer good performance from 30 MHz to 600

MHz, while traditional dielectric foam absorbers deliver perfor-

mance satisfaction above 500 MHz. The combination of the

two can yield precarious results if the selected materials have

mismatched impedance characteristics.

With proper impedance matching, these two materials can be

joined to create a hybrid absorber structure that benefits from

the inherent performance characteristics of each of the indivi-

dual materials. The AEPH series of EMC absorbers incorpo-

rates a urethane pyramidal absorber structure which can be

precision matched to any brand of tuned ferrite tile absorbers.

The resulting product delivers super-broadband reflectivity

performance from 20 MHz to 40 GHz!

Specifications

AEPH-60-CR1

Height

in

63.75

cm

161.92

@ 30 MHz dB

-19

@ 125 MHz dB

-26

@ 250 MHz dB

-29

@ 500 MHz dB

-29

@ 1 GHz dB

-30

@ 18 GHz dB

-42

@ 40 GHz dB

-45

Power

kW/m

2

1.5

Weight

Ibs/pc.

23.0

kg/pc.

10.4

Fire retardancy

NRL 8093 Test, 1,2 and 3,

ISO 11925-2, DIN 4102 Class B2

Powered by

© MVG 2014 - Graphic design: www

.ateliermaupoux.com, pictur

es: all rights r

eserved.

Pr

oduct specifications and descriptions in this document ar

e subject to change without notice. Actual pr

oducts may dif

fer in appearance fr

om images shown.

Contact your local sales representative

for more information

www.microwavevision.com

[email protected]

[email protected]

Absorption @

Normal Incidence

Ordering code

AEPH-XX – CRX, where XX designates absorber height

in inches and CRX designates Clean Room Class

Unique Manufacturing Process

After the standard manufacturing process, the absorbers

undergo a specific procedure to remove any loose debris

left from the manufacturing process, then are coated with

a special latex binder.

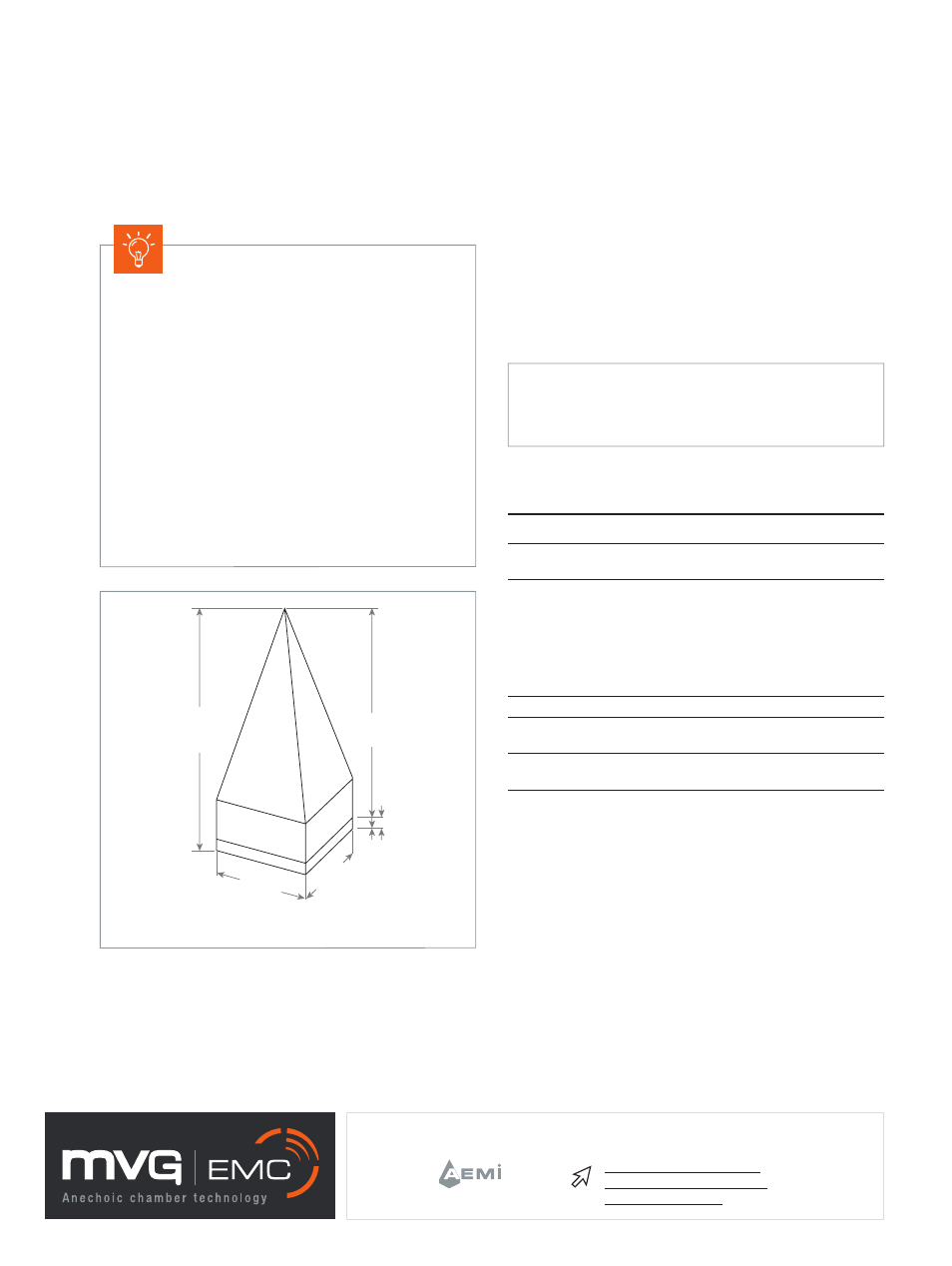

AEPH-60-CR1 mechanical drawing

23.62 in

(60 cm)

23.62 in

(60 cm)

63.22 in

(160.58 cm)

60 in

(152.4 cm)

3 in

(7.62 cm)

0.22 in (5.5 mm)