VICI Selectors (multiposition) Standard electric User Manual

Page 17

3. Establish a flow of clean gas (50 psi is adequate) into the port offset

away from the actuator. This port, called the alignment inlet in

Figure 10,

will be the designated inlet throughout this procedure.

STUW

Establish gas flow into the common port at 6 o’clock (alignment inlet

in

Figure 10).

4. With the valve facing you and the actuator behind the valve, the port

to the left of or counterclockwise from the alignment inlet corresponds

to Position 1. (See

Figure 10. This is the opposite of valves on air

actuators.)

STUW

With the common port at 6 o’clock as the alignment inlet, the port to

the left of or counterclockwise from the common port at 12 o’clock

corresponds to Position 1.

If the gas is flowing from the port in Position 1, go to Step 5. If you hear

no flow, grip the valve and rotate it either way as necessary (the actuator

keeps the rotor fixed) until gas flows from this port.

NOTE: When listening for flow, it is helpful if the fittings are removed from

the port under consideration but left in the adjacent ports. If all the fittings

have been removed, install a loop connecting the two adjacent ports to bet-

ter isolate the sound of the flow.

5. Grip the valve and rotate it counterclockwise a few degrees past the point

where flow stops.

This sets up a “staging area” for the approach to Position 1.

6. Grip the valve and slowly rotate it clockwise until the first traces of flow

are heard from the port of Position 1. (The port to the left of the alignment

inlet.)

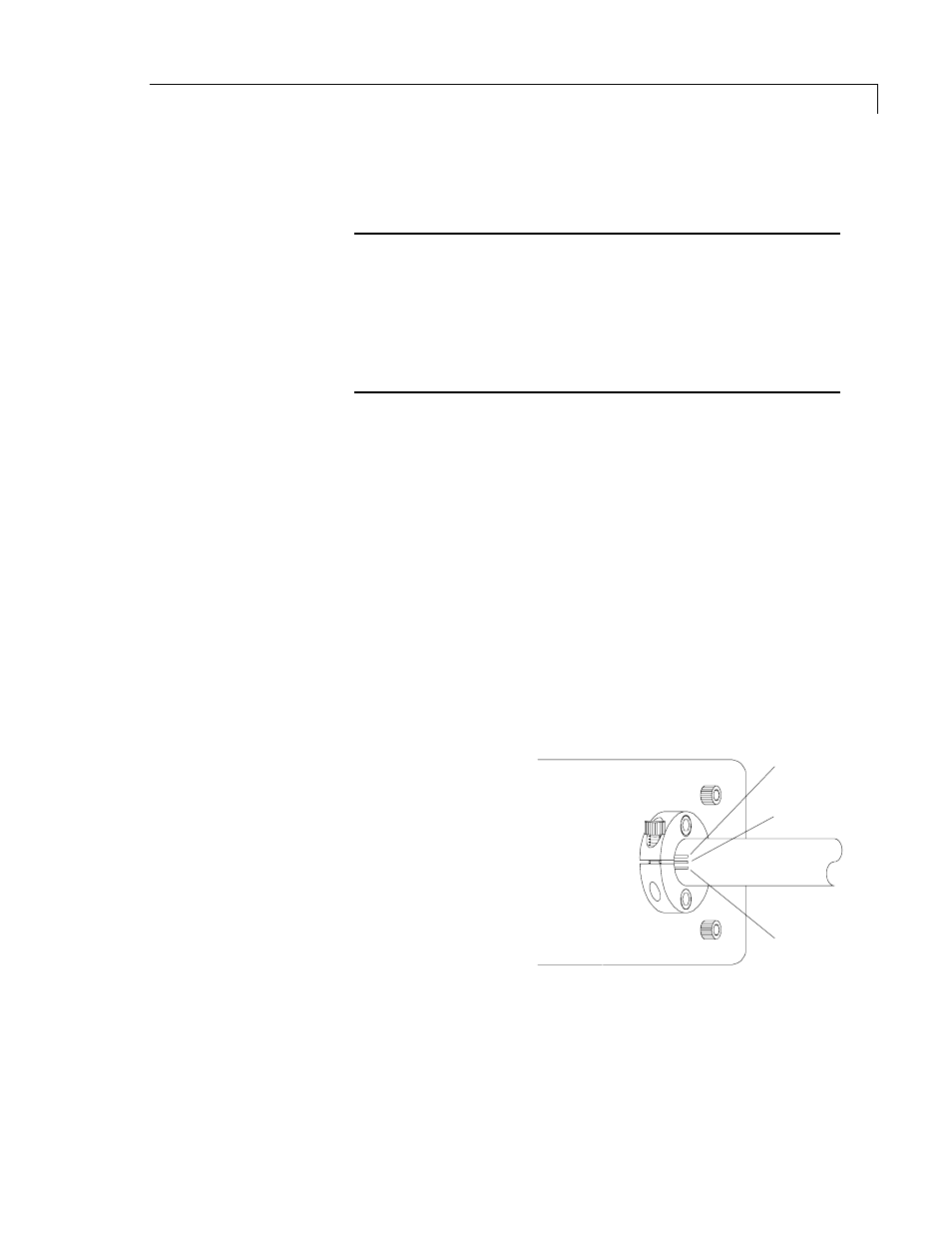

7. While holding the valve

steady, use a soft pencil or

ink marker to make a mark

on the standoff correspond-

ing to the slot in the actuator

clamp ring. This slot makes

a clear fixed reference point

for observing relative rota-

tional positions. In the case

of a closemount valve, make

this mark on the valve body.

(

Figure 11)

8. Continue the slow manual clockwise rotation of the valve body through

the point of peak flow and beyond until the flow stops or is barely percep-

tible, as in Step 6.

9. Make another mark as in Step 7. (

Figure 11)

10. Make a third pencil mark halfway between the first two and rotate the

valve counterclockwise until this midway mark is reached. (

Figure 11)

����������

��������

����������

���������

�����������

��������

������������������������������������

��������������������������

Valve Alignments