Maintenance – Triton TPT 125 User Manual

Page 9

9

GB

MAINTENANCE

WARNING! Always ensure that the tool is switched off and

the plug is removed from the power point before making

any adjustments or carrying out maintenance

• Any damage to this tool should be repaired and

carefully inspected before use, by qualified repair

personnel

• Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained

Cleaning and lubrication

• After use, vacuum the planer machine to remove wood

chips, sawdust and debris

• Use a cleaning solution (not included) to remove resin

and grease residue

• Remove sawdust, wood chips and grease from chains

and gears

• The bearings in motor and cutter head units are

factory-sealed and should require no further lubrication

• Four components require regular lubrication:

- Rollercase vertical screw mechanism (x2)

- Rollercase lock cam

- Rollercase vertical rails (x4)

- Feed roller chain drive

• Remove the top and both side panels to access these

components

• Clean the chain drive before lubrication. Use spray oil

(not included) to lubricate the chain. Allow time for the

lubricant to penetrate between the links, then wipe the

surface of the chain dry

• Remove any residues of grease from the other

components, using mineral spirits if necessary, then

apply a coat of light grade multi-purpose grease (not

included)

• The work table and extension table can be coated with

a very thin coat of lubricating wax (not included) to

protect the surface from rust and to facilitate smooth

feed during operation

Re-aligning the rollercase

• Test the blade alignment by

running two pieces through

each side (left and right) of

the planer

• Measure and compare

results to check that the

blades are correctly aligned

and/or to determine the

amount of correction

required

• To correct any misalignment:

1. Turn the planer off and

remove the plug from the

power source

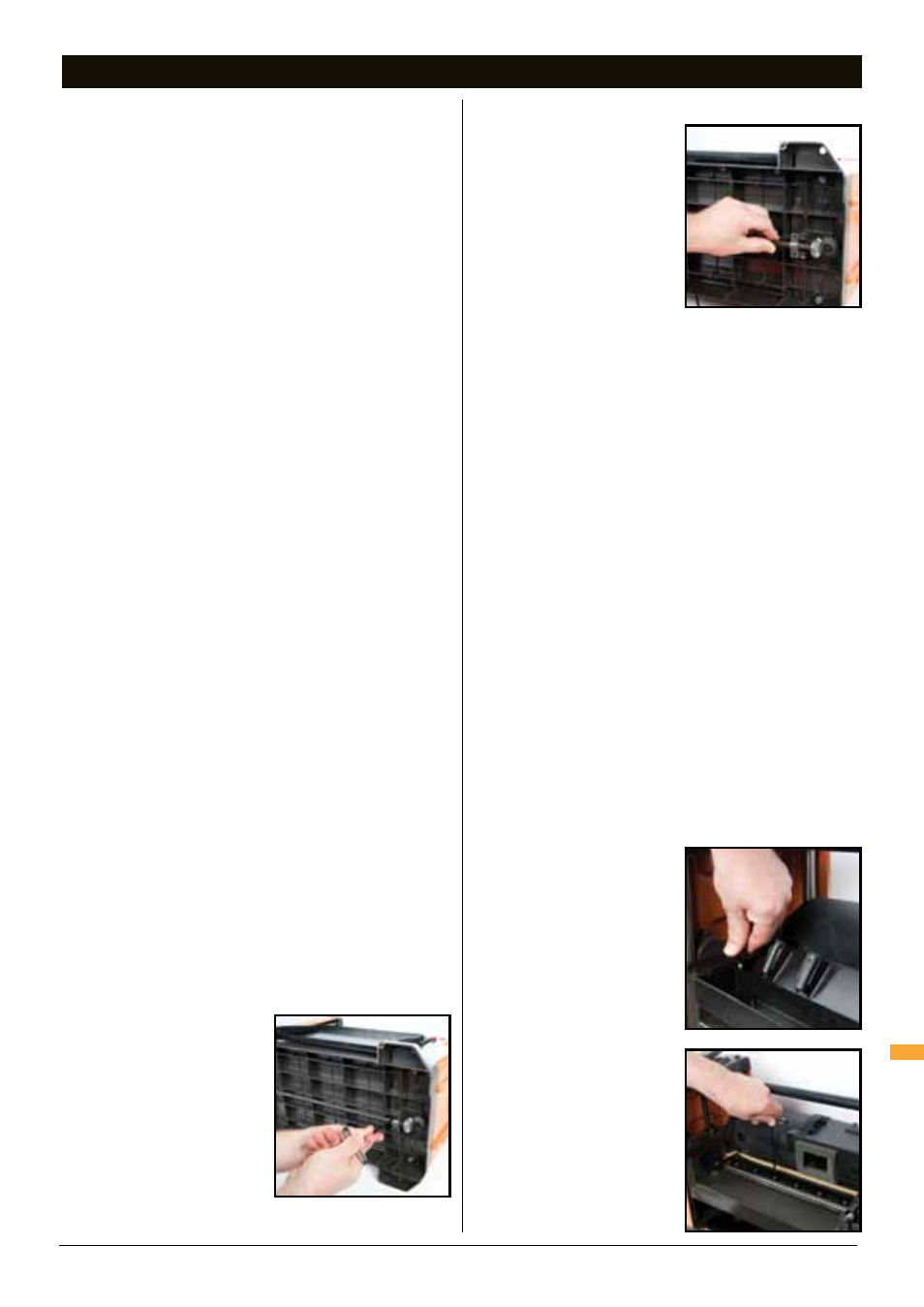

2. Carefully place the planer on

its back

3. Remove the screws to the

horizontal spindle retaining

bracket on the Crank Handle

(9) side of the planer.

4. Carefully disengage the gears

5. Slowly rotate the crank handle to raise or lower the

rollercase as needed to re-position it on the vertical

screw

6. Rotate the crank handle forward or back as required in

order to correct the misalignment. Each complete turn

of the crank handle will make an adjustment of 0.15mm

(0.006")

7. Re-engage the gears and re-fit the horizontal spindle

retaining bracket

8. Carefully sit the planer upright again

9. Carry out a test run to check the rollercase is now level

10.Repeat the correction process if further adjustment is

necessary

Checking and replacing the blades

Inspecting the blades:

1. Locate the Blade Cover Panel (17) on the back of

planer. Loosen and remove the thumb screws on either

side and lift off the panel

2. Identify the cutter head inside, and the TWO sharp

blades on the cutter head

3. Without touching the blades, carefully turn the cutter

head until the self-engaging

latch clicks to lock the

cutter head.

4. Use the Hex Key (15) to

remove the six bolts on the

blade cover plate

5. Using the two Magnets (19),

carefully remove the blade

cover plate

6. Then use the magnets to

remove the blade

7. Inspect the blade for signs

of wear or damage. A blade

that is dull, worn, nicked,

torn or uneven can result

in poor performance such

as fuzzy, chipped or raised

grain, raised edge and

uneven cut

Maintenance

Fig.4

Fig.5

Fig.6

Fig.7