3start-up, 1 performance charts – Trebor 620R Magnum User Manual

Page 10

PAGE 10

MAGNUM 620R PUMP OPERATION / MAINTENANCE MANUAL

3

START-UP

Pump air supply pressure must be regulated. (See Figure 3-3: Pressure vs.

Open the fluid suction (IN) line valve, if necessary.

Open the fluid discharge (OUT) line valve, if necessary.

Start slowly with air regulator at low (> 20 psi) pressure setting. Increase

pressure to attain desired flow, up to the maximum rating (See Section 3.1).

Table 1: Consumption / Efficiency can be used to determine approximate air

consumption.

Refer to Troubleshooting, Section 5, if pump fails to start.

ATTENTION: Prolonged periods (> 5 minutes)

of dry running can damage

critical internal pump parts.

CAUTION: When handling potentially dangerous fluids under pressure,

the pump and its fittings should be placed in an enclosure away from operators.

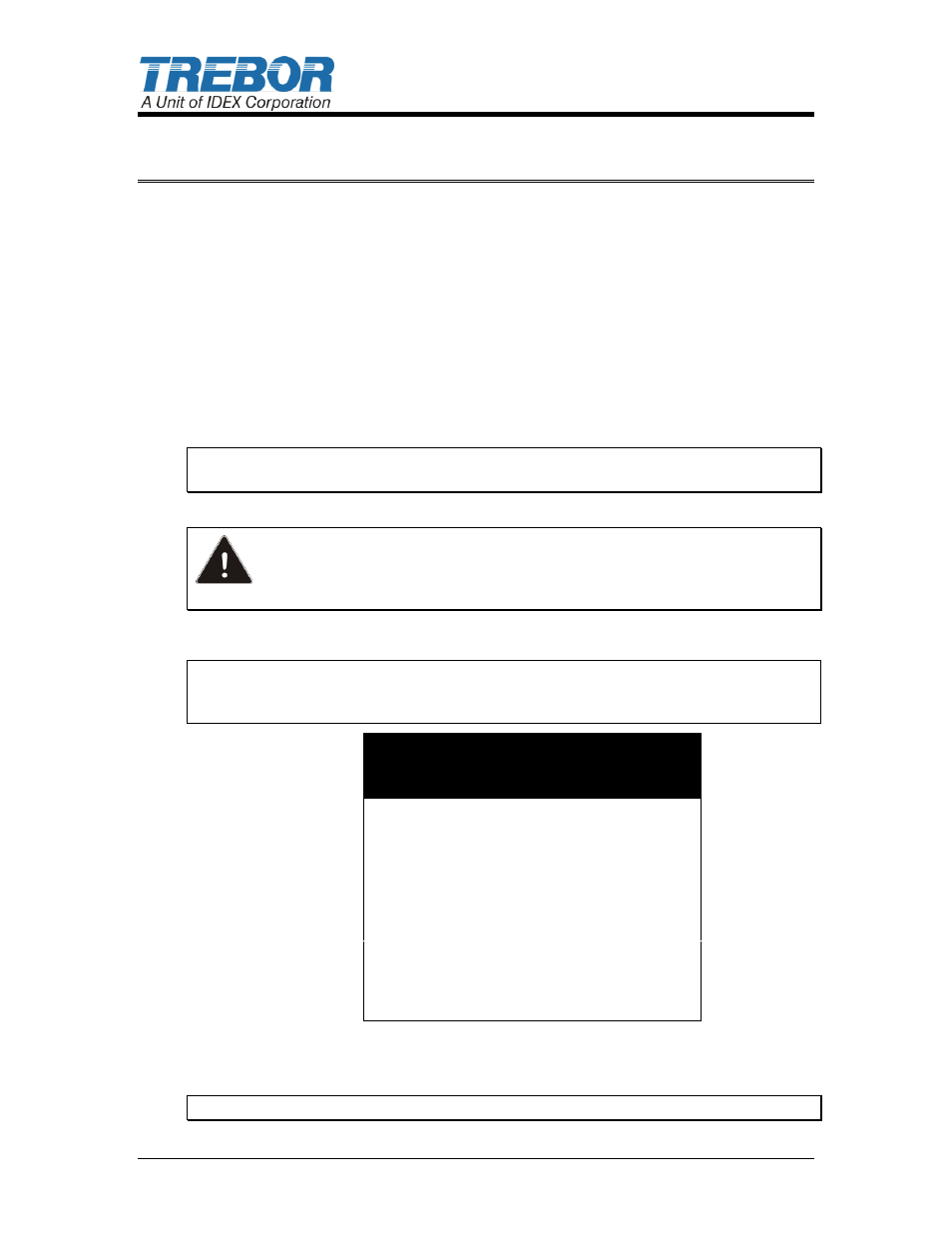

3.1 PERFORMANCE CHARTS

Pumping capacity is a function of air supply pressure and volume, suction head,

suction line restrictions, discharge head, discharge line restriction, and fluid

specific gravity and viscosity.

Air Supply

Pressure

(PSIG)

Discharge

Fluid

Pressure

(PSIG)

Air

Used

(SCFM)

Flow*

(GPM)

20

0

4.5

7.2

20

10

3.4

5.3

30

0

7.1

8.1

30

15

5.6

6.0

40

0

9.8

8.6

40

20

7.7

6.3

50

0

12.6

9.7

50

25

10.1

6.9

60

0

15.3

10.5

60

30

12.2

7.2

70

0

18

11.1

70

35

14.9

9.3

80

0

20.6

11.4

80

40

18.3

7.3

Table 1: Consumption / Efficiency

*With check muffler spring assembly removed (see Section 1.3).

NOTE: Specification to be used to size regulators and control valves.