4 check muffler operation – Trebor 610NM Magnum User Manual

Page 5

MAGNUM 610NM PUMP OPERATION / MAINTENANCE MANUAL

PAGE 5

1.4 CHECK MUFFLER OPERATION

1.4.a Purpose

Permits pump to operate reliably in systems that incorporate a discharge fluid

“dead head” condition. (Pump air supply remains on while discharge port is

closed.)

Permits pump to operate reliably in systems that have the pump located at an

elevation below the liquid supply level. (Pump air supply remains on.)

Effectively reduces the amount of harmful acid vapors that can enter into the

pump’s internal air circuit components while the pump air supply is off. (A

common cause of shuttle and pilot valve failures.)

1.4.b Adjustment

The Check Muffler is preset at the factory to a setting that makes the pump

“Dead Cycle” at a slow constant rate with the fluid discharge port closed, and

the pump air supply at 45 psig. This setting also allows the pump to operate

with approximately 4 ft. (1 meter) of H

2

O positive fluid supply pressure.

“Deadheading” at other air supply pressure or with more positive fluid supply

pressure (fluid source above pump) may require user adjustment. The

adjustment should control the pump to a slow, steady “Dead Cycle” rate with

no erratic cycling/”machine gunning” evident.

NOTE: If pump application does not require operation in either of these

conditions, loosen check muffler adjustment for minimum restriction.

NOTE:

Air consumption during “Dead Cycling” is very little since the pump

diaphragms are displacing only internal bypass.

“Dead Cycling” should be

considered as a standby idle mode.

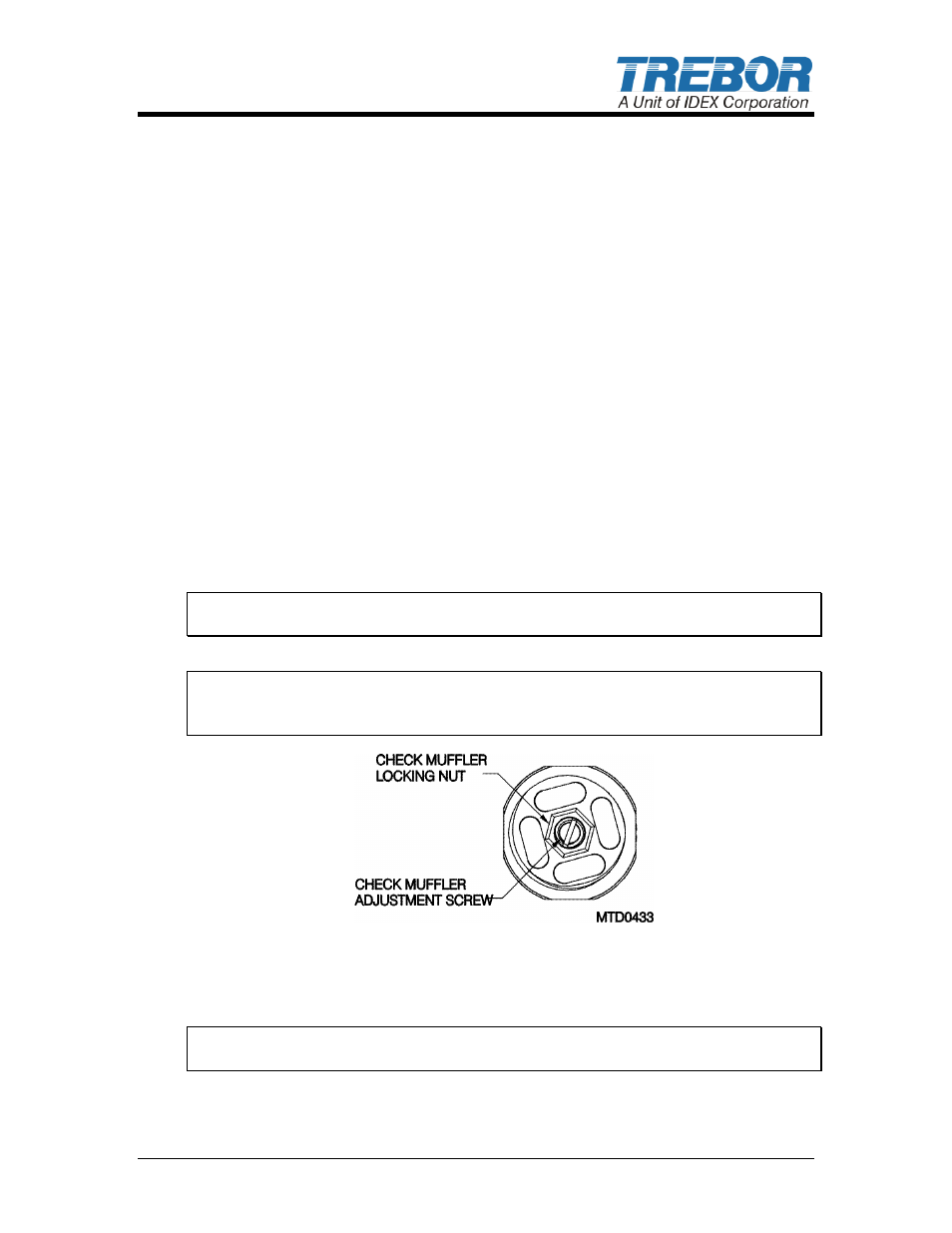

Figure 1-2

Turn adjustment screw clockwise (CW) to increase back pressure.

Turn adjustment screw counter-clockwise (CCW) to decrease back pressure.

NOTE: Loosen locking nut prior to making adjustment and tighten nut to maintain

adjustment.