Rite-Ride 4173 User Manual

Page 2

AIR LINE TO

INFLATION VALVE

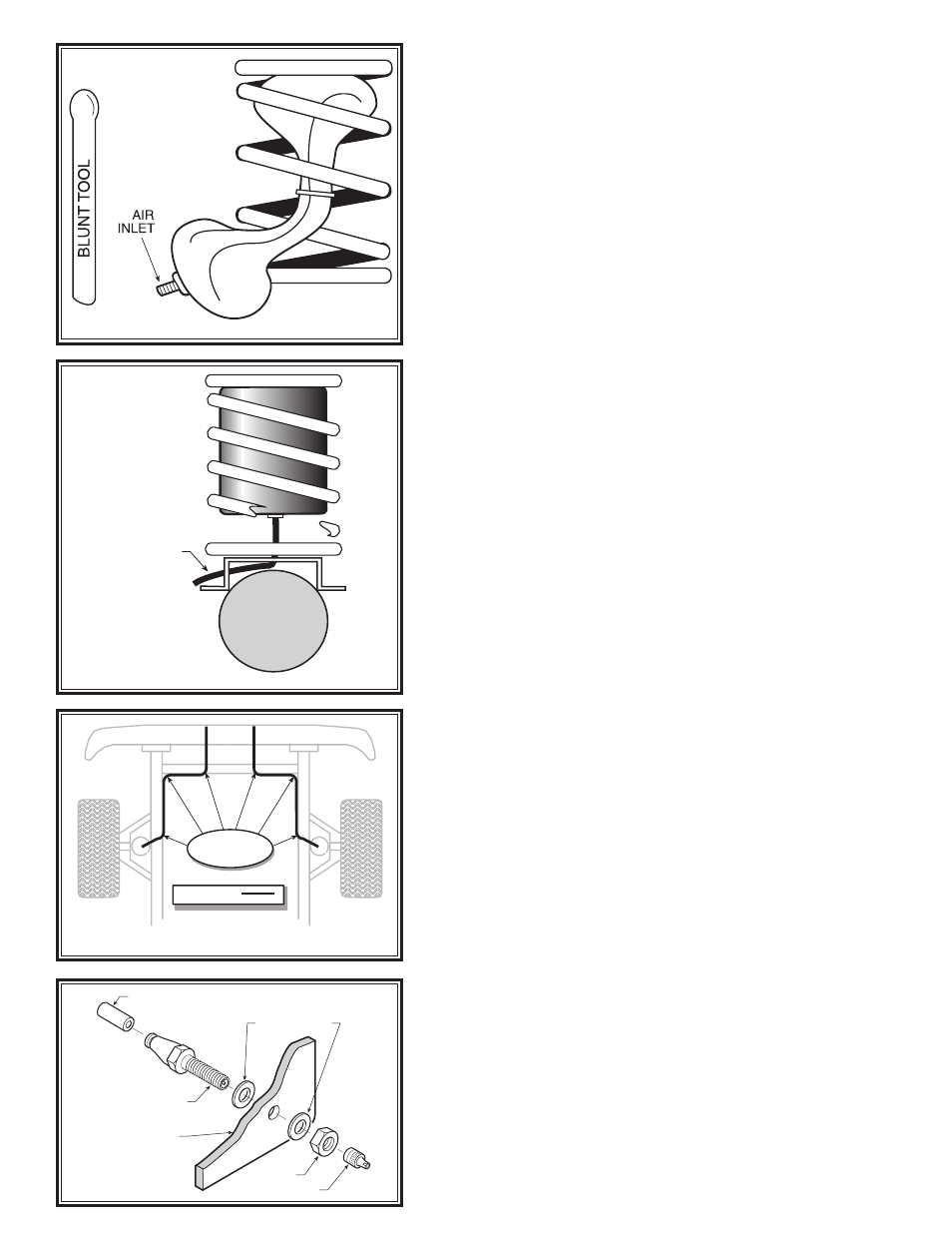

Figure “B”

STEP 1— AIR SPRING PREPARATION

Remove the inflation valve cap from the inflation valve on

the air spring. Using the valve cap as a core tool from the

inflation valve, remove the inflation valve core from the air

spring. Exhaust the air spring by pushing it flat then re-insert

the valve core back into the air spring to keep it collapsed.

STEP 2—INSTALLING THE AIR SPRING

Insert the top of the flattened air spring into the coil spring

through the lowest opening with the inflation valve inlet at

the bottom as shown in Figure “A”.

STEP 3—ADJUSTING THE AIR SPRING

Push the air spring up into the coil spring by hand or with a

blunt tool. DO NOT use anything with sharp edges or corners

as this may damage the air spring.

When the air spring is completely within the coil spring,

remove the valve core to let the air back into the air spring.

Allow the air spring to return to its normal shape.

Install the spacer on top of the air spring. See Figure

“B”. Once the weight of the vehicle is applied to the sus-

pension aid the air springs are pressurized, the spacer will

stay in place.

STEP 4— REATTACH THE SHOCK ABSORBER

Attach shock absorbers if removed earlier in the installation.

Torque to manufactures specifications.

STEP 5— ROUTE THE AIR LINE

Cut the remaining air line tubing into two equal lengths (cut

the tubing as squarely as possible). Select a location for the

inflation valves in a protected area, such as the bumper or fuel

fill floor (

Note: The inflation valve will be installed in Step 6).

Insert the air line tubing into the push-to-connect fitting

on the air spring as far as possible. Route the tubing from

the air spring to the inflation valve, making sure to avoid

direct heat from the engine, exhaust pipe and away from

sharp edges. Secure with Nylon ties provided in your kit.

STEP 6—INSTALL THE AIR LINE AND INFLATION

VALVE

Select a location on the vehicle for the air inflation valves.

The location can be located on the bumper or the body of

the vehicle, as long as it is in a protected location so the

valve will not be damaged, but maintain accessibility for the

air chuck see Figure “C”. Drill a 5/16" hole and install the

air inflation valve using two 5/16" flat washers per valve as

supports see Figure “D”.

FOLLOW STEPS 1-6 FOR THE OTHER SIDE OF THE

VEHICLE.

STEP 9— INFLATE AND TEST

Inflate the air springs to recommended operating pressure

(see page 1 for operating pressures). With a soap and water

solution, check for air leaks around the fittings and valve core.

We recommend inflating and deflating in 5 psi increments to

find the ideal riding condition for your vehicle.

STEP 10— COMPLETION

This now completes the installation. Install. Raise the vehicle

and remove the jack stands and lower the vehicle back onto

the ground. Inflate the Coil-Rite air helper springs to 5 psi.

NOTE: Check air pressure on a monthly basis.

Figure “A”

Figure “C”

NYLON TIES

AIR LINE

REAR

BUMPER

AIR LINE

PUSH-TO-CONNECT

INFLATION VALVE

FLAT WASHER

HEX NUT

VALVE CAP

BODY OF

VEHICLE

Figure “D”