Rite-Ride 4192 User Manual

Page 2

STEP 1—VEHICLE PREPARATION

Remove the negative battery cable. With the vehicle on a solid level surface, chock the front wheels. Using a jack

rated for the weight of your vehicle, raise the wheels off the ground. Lower the vehicle frame onto jack stands rated

for the vehicle weight, making sure the suspension is fully extended. (Do not use wood or concrete blocks to support

the vehicle.) Your vehicle is equipped with jounce bumpers attached to the frame, inside the coil springs. Remove

the jounce bumpers by pulling down at an angle (The jounce bumpers will not be reused). Next, drill a 7/16" hole in

the jounce bumper mount in the anticipated direction of the air line,

see Figures “C”, “D”, & “E”.

STEP 2 — SHOCK ABSORBERS

If necessary, additional clearance between the coil windings may be obtained by removing the shock absorbers from

the lower mounts and lowering the suspension an additional one to two inches.

(CAUTION: Do not put tension or

strain on the flexible brake lines.)

STEP 3— AIR SPRING PREPARATION

Cut a two inch piece of air line tubing making sure the tubing is cut as square as possible (a “saw” cut with a sharp

knife is preferred). Install the tubing into the push-to-connect air inlet on the air spring. Exhaust the air from the air

spring by rolling it up towards the air inlet. After the air is exhausted, install the plug into the tubing coming out of

the air spring,

see Figure “A”.

STEP 4 — INSTALL THE AIR SPRING

Insert the top of the flattened air spring into the coil spring through the lowest opening in the coil spring with the

air inlet at the top of the coil spring,

see Figures “A”, “B”, & “D”. Push the air spring into the coil spring by hand

or with a blunt tool.

DO NOT use anything with sharp edges or corners, as damage may occur. When the air

spring is completely within the coil spring, remove the plug and allow the air spring to return to its normal shape.

Push the air spring to the bottom of the coil spring and insert the protector over the air line and onto the top of the

air spring. Install the union elbow on to the end of the air line.

See Figures “B” & “D”. For installation on the right

side, repeat Steps 2 through 4.

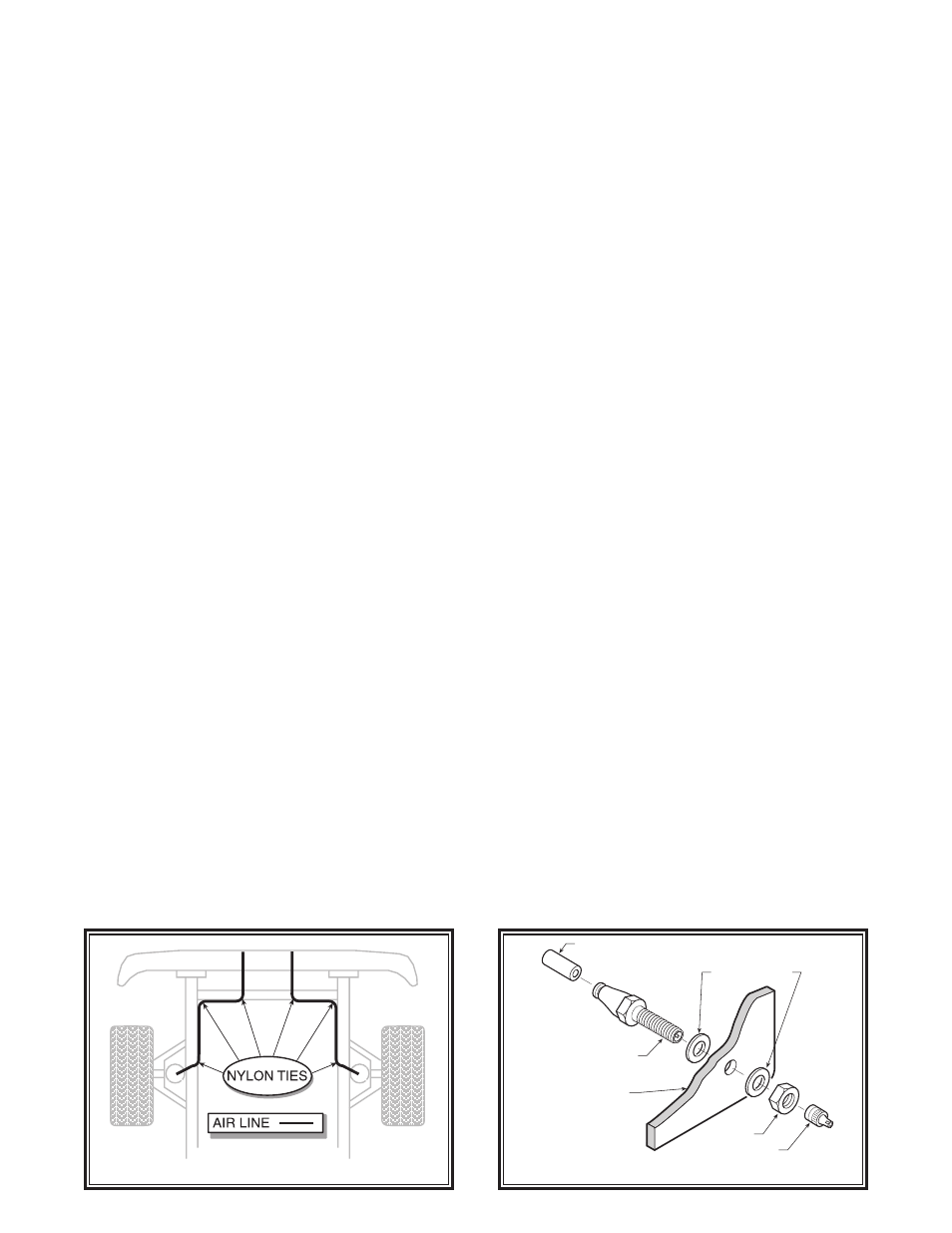

STEP 5— ROUTE THE AIR LINE

Select a location for the inflation valves in a protected area such as on the bumper or body. Use a sleeve protector

on the air line to protect the tubing where it passes through the jounce bumper mount. Route the air line from the

union elbow, through the 7/16” hole drilled in step 1, to the inflation valves

(Figure “E” & “F”). Avoid any sharp

edges or hot surfaces as well as sharp angles. The air line can be secured with the nylon ties provided. Install the

inflation valves into 5/16” holes,

see Figure “F”. Cut off any excess air line using the method mentioned above and

push the end as far as possible into the inflation valve.

STEP 7— INFLATE AND TEST

Inflate the air springs to recommended maximum operating pressure (see page 1 for operating pressures). With a

soap and water solution, check for air leaks around the fittings and valve core. Inflate and deflate in small increments

to find the ideal riding conditions for your vehicle.

STEP 8— COMPLETION

Re-attach the shocks if necessary and the wheels. Torque all nuts and lug nuts to manufacture’s specifications. Raise

the vehicle, remove the jack stands, and lower the vehicle to the ground. Reattach the battery cable.

AIR LINE

PUSH-TO-CONNECT

INFLATION VALVE

FLAT WASHER

HEX NUT

VALVE CAP

BODY OF

VEHICLE

FIGURE “E”

FIGURE “F”