Rite-Ride 2476 User Manual

Page 3

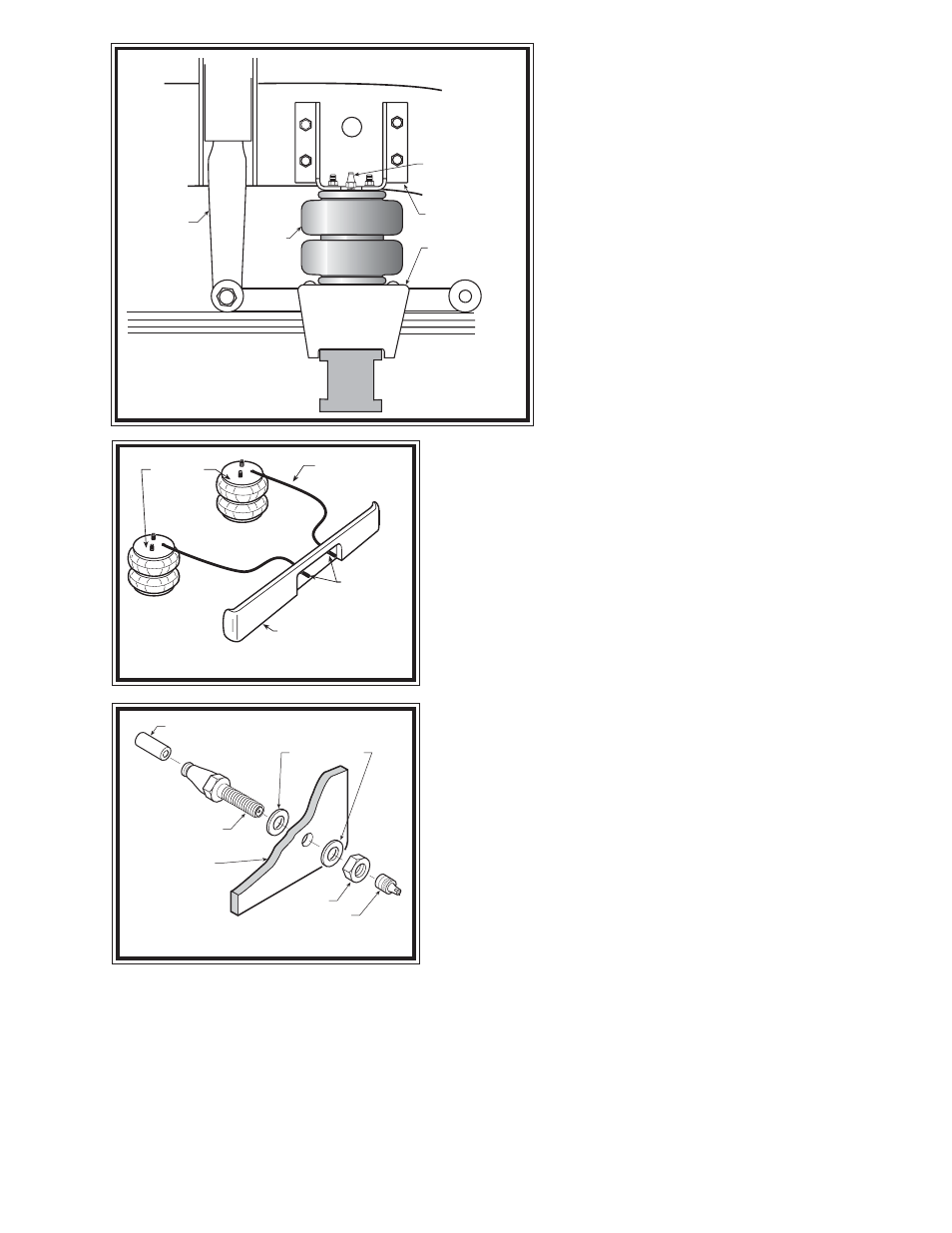

AIR

SPRING

FRAME

SHOCK

ABSORBER

LOWER

BRACKET

UPPER

BRACKET

AIR FITTING

S

TEP

1 - P

REPARE

THE

VEHICLE

With the vehicle on a solid, level surface chock

the rear wheels. Raise the vehicle by the front axle

and remove the front wheels. After the removal of

the wheels, lower the vehicle so that the axle rests

on jack stands rated for your vehicle's weight.

Remove the negative battery cable.

S

TEP

2 - P

RE

-

ASSEMBLE

THE

KIT

Pre-assembly will begin with the right, or

passenger's side of the vehicle. All illustrations

show the right side installation and assembly unless

noted otherwise.

Select one air spring from your kit. Install the air

fitting as shown in Figure "A". Tighten the air

fitting securely to engage the orange thread sealant.

Install the upper bracket by inserting the studs on the

top of the air spring into the smaller holes, see

Figure "A". Using two 3/8" -16 flanged hex nuts,

secure the upper bracket to the air spring.

Select one lower bracket and install the 3/8"-16x3-1/2" carriage

bolts into the square holes. Attach the lower bracket to the bottom of

the air spring using a 3/8" -16 x 3/4" flanged hex bolt. See Figure "A".

S

TEP

3 - I

NSTALL

THE

ASSEMBLY

TO

THE

VEHICLE

Place the assembly on top of the leaf stack centered over the axle.

The carriage bolts will pass through the holes in the shock mount, next

to the axle U-bolts. Slide the lower clamp bracket into place against

the U-bolts with the carriage bolts passing through the holes. Install

the 3/8-16 flange lock nuts onto the carriage bolts, securing the

assembly to the leaf stack. See Figure's "A" & "B".

Using the upper bracket as a template, mark and drill four 7/16"

holes into the frame. Attach the upper bracket to the frame with four

3/8"-16x1" hex bolts and flange lock nuts. See Figures "A" & "B".

S

TEP

4 - I

NSTALL

THE

PASSENGER

'

S

SIDE

ASSEMBLY

Follow steps 1 - 3 for the assembly and installation of the left, or

driver's side assembly.

S

TEP

5 - I

NSTALL

THE

AIR

LINE

AND

THE

INFLATION

VALVES

Uncoil the air line tubing and cut it into two equal lengths. DO NOT

FOLD OR KINK THE TUBING. Try to make the cut as square as

possible. Insert one end of the tubing into the fitting installed in the top

of the air helper spring. Push the tubing into the fitting as far as

possible see Figure "A".

Select a location on the vehicle for the air inflation valves. The

location can be on the bumper or the body of the vehicle, as long as it is in a protected location so the valve will not

be damaged, but maintain accessibility for the air chuck see Figure "C". Drill a 5/16" hole and install the air inflation

valve using two 5/16" flat washers per valve as supports see Figure "D". Run the tubing from the air helper spring

to the inflation valve, routing it to avoid direct heat from the engine, exhaust pipe, and away from sharp edges. Thermal

sleeves have been provided for these conditions. If a thermal sleeve is required, simply slide the sleeve over the air

line tubing to the location requiring protection. The air line tubing should not be bent or curved sharply, as it may buckle.

Secure the tubing to the vehicle with the nylon ties provided. Push the end of the air line tubing into the inflation valve

as far as possible see Figure "E".

S

TEP

7 - C

HECK

THE

AIR

SYSTEM

Figure "B"

Figure "D"

Figure "C"

AIR HOSE

INFLATION

VALVES

BUMPER

AIR

SPRINGS

AIR LINE

PUSH-TO-CONNECT

INFLATION VALVE

FLAT WASHER

HEX NUT

VALVE CAP

BODY OF

VEHICLE