Rite-Ride 2558 User Manual

Page 3

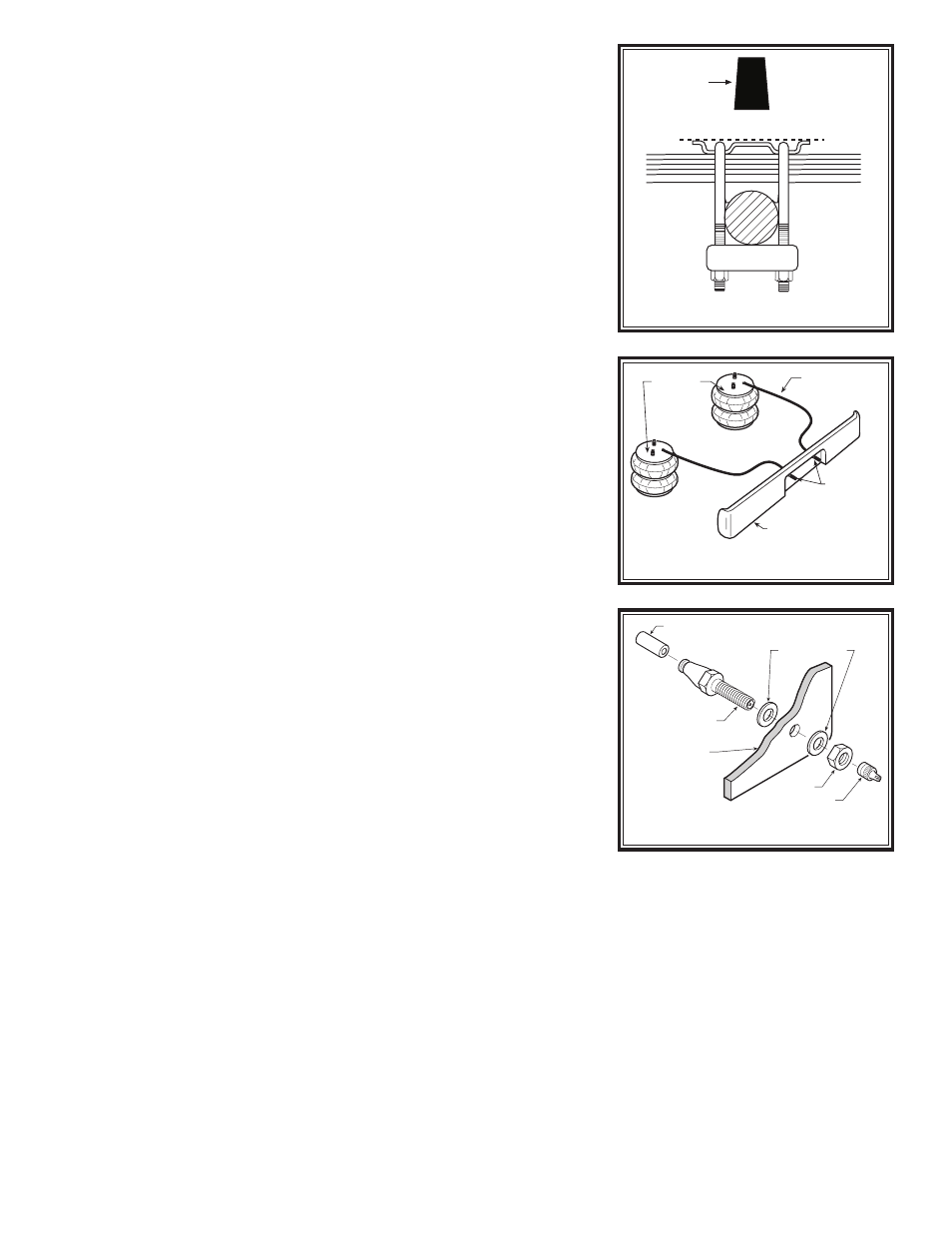

Figure “D”

STEP 1— PREPARE THE VEHICLE

Place the vehicle on a solid level surface. Take necessary safety pre-

cautions such as using wheel chocks when working under your vehicle.

Remove the jounce bumpers by cutting them off as close to the bracket

as possible as shown in Figure “B”.

STEP 2— PREASSEMBLE THE KIT

Select the left upper bracket and an air spring from your kit. Attach the

upper bracket to the air spring with a 5/8" nylock nut. Install the male

fitting into the air spring. Tighten the air fitting securely to engage the

orange thread sealant. No additional thread sealant is needed, (see

Figure “A”). Attach the lower bracket to the air spring using the 3/8"-16

x 3/4" hex bolt. Tighten the bolt making sure the bracket is in the correct

position (see Figure “A”).

STEP 3— INSTALL THE PREASSEMBLY TO THE VEHICLE

Place the preassembly on the leaf stack of the left side of the vehicle

as shown in Figure “A”. Attach the upper bracket directly beneath the

frame rail using the 3/8" - 16 x 3.6" bail clamps OR the 3/8"-16 x 4" bail

clamp (2008 and newer), and 3/8" lock nuts. Attach the lower bracket to

the leaf stack using the 5-1/2" carriage bolts, 3/8" lock nuts, and bracket

straps, (see Figure “A”).

Follow the same procedures as outlined in Steps 1 through 3 for

installing the right side of the vehicle.

STEP 4— INSTALL THE AIR LINE

Uncoil the air tubing and cut it into two equal lengths.

DO NOT FOLD

OR KINK THE TUBING. The air line tubing should not be bent or curved

sharply as it may buckle with age. Make the cut as square as possible.

Insert one end of the tubing into the elbow fitting installed in the top of

the air helper spring.

Select a location on the vehicle for the air inflation valves. The locations

can be on the bumper or the body of the vehicle but be sure that it is in a

protected location so the valve will not be damaged yet still be accessible

for the air chuck (see Figure “C”). Drill a 5/16" hole or use an existing

hole and install the air inflation valve using two 5/16" stainless steel flat

washers per valve as supports (see Figure “D”). Run the tubing from

the air spring to the inflation valve, routing it to avoid direct heat from the

muffler or tailpipe, and away from sharp edges. Tubing protectors have

been provided for these conditions. Push the end of the air line tubing

into the inflation valve as illustrated (see Figure “D”). Secure the tubing

in place with the nylon ties provided.

STEP 5— CHECK THE AIR SYSTEM

Once the inflation valves are installed, inflate the air springs and check

the fittings for air leaks with an applied solution of soap and water. If a

leak is detected at a tubing connection then check to make sure that the

tube is cut as square as possible and that it is pushed completely into the

fitting. The tubing can easily be removed from the fittings by pushing the

collar towards the body of the fitting and then pulling out the tube. If a leak

is detected where the fitting screws into the spring, screw the elbow into

the spring until the leak stops. Reinflate the air helper springs and check

for leaks as noted above. Further information on trouble-shooting can

be found in the General Operation Instruction book included with this kit.

This now completes the installation. Before proceeding, check once

again to be sure you have proper clearance around the bellows.

With a

load on your vehicle and the helper air springs inflated, you must

have at least 1/2" clearance around the bellows. As a general rule,

the Ride-Rite Air Helper Springs will support approximately 32 lbs. of load

for each p.s.i. of inflation pressure (per pair). For example, 50 P.S. I. of

inflation pressure will support a load of 1600 lbs. per pair of air helper

springs.

FOR BEST RIDE use only enough air pressure in the air helper

springs to level the vehicle when viewed from the side (front to rear).

This amount will vary depending on the load, location of load, condition

of existing suspension and personal preference.

Figure “B”

CUT LINE

JOUNCE

BUMPER

AIR HOSE

INFLATION

VALVES

BUMPER

AIR

SPRINGS

Figure “C”

AIR LINE

PUSH-TO-CONNECT

INFLATION VALVE

FLAT WASHER

HEX NUT

VALVE CAP

BODY OF

VEHICLE