Rite-Ride 2212 User Manual

Page 3

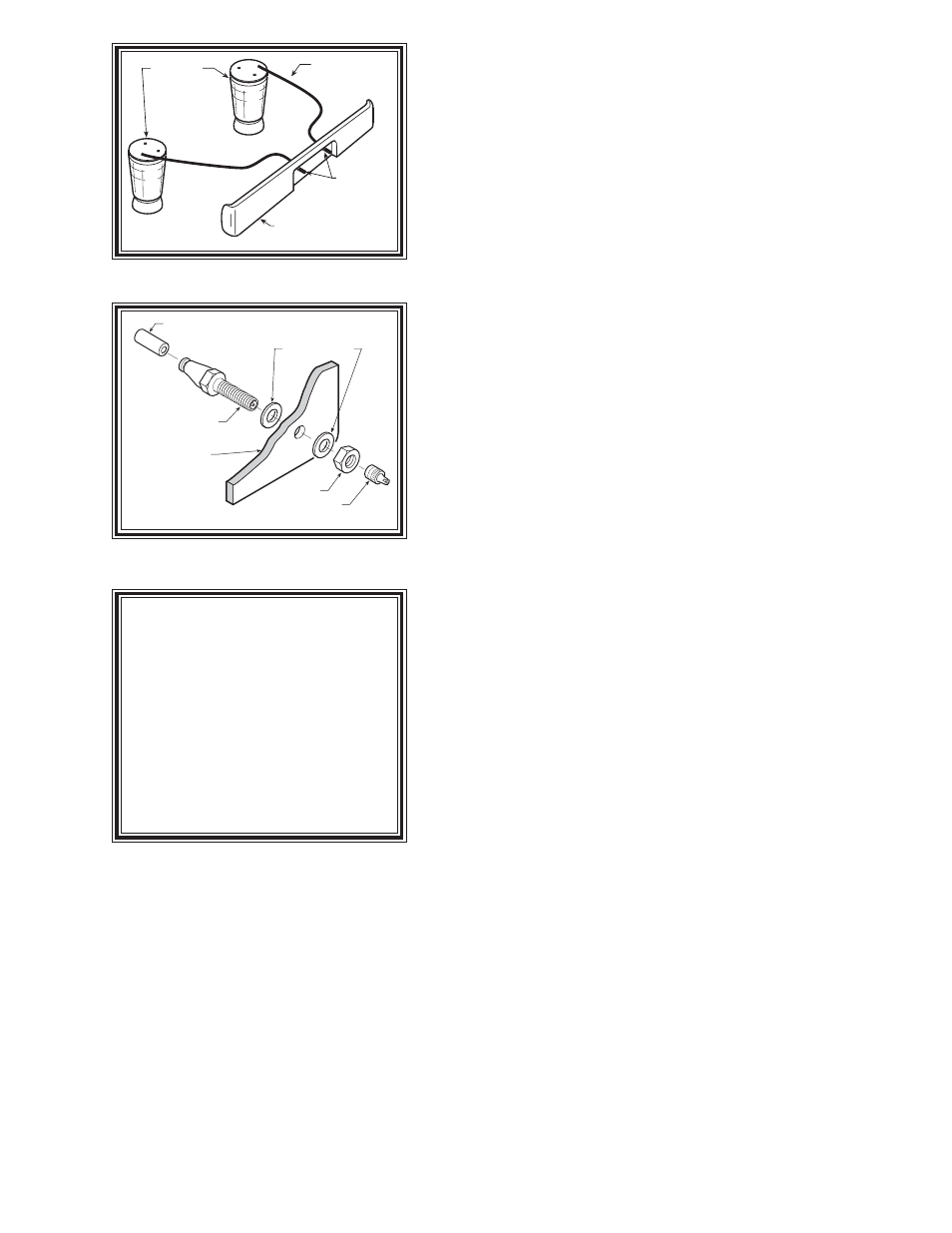

AIR LINE

PUSH-TO-CONNECT

INFLATION VALVE

FLAT WASHER

HEX NUT

VALVE CAP

BODY OF

VEHICLE

AIR HOSE

INFLATION

VALVES

BUMPER

AIR

SPRINGS

Figure "B"

Figure "C"

S

TEP

1 - P

REPARE

THE

VEHICLE

With the vehicle on a solid level surface chock the front wheels.

Raise the vehicle by the rear axle and remove the rear wheels. After

the removal of the wheels, lower the vehicle so the axle rests on jack

stands rated for your vehicles weight. Remove the negative battery

cable.

S

TEP

2 - P

REASSEMBLE

THE

KIT

Select one air helper spring from the kit. Install the upper

bracket by aligning the threaded holes on the air spring with the

small holes on the upper bracket. Fasten the upper bracket to the air

spring using the 3/8"-16 x 3/4" hex bolts as shown in Figure "A".

Install the air fitting as shown in Figure "A". Tighten the air fitting

so as to make contact with the nylon ring and then tighten 1/4 turn

to snug the fitting. No thread sealant is needed. Insert the two 3/8"-

16 x 3-1/2" carriage bolts into the lower bracket. Next, attach the lower

bracket and disk to the air spring using the 3/8"-16 x 3/4" hex bolt see

Figure "A". Refer to Figure "A" for proper orientation of the lower

bracket.

S

TEP

3 - A

TTACH

LOWER

BRACKET

TO

LEAF

SPRING

Place the assembly on the driver’s side on top of the leaf spring

stack forward of the axle see Figure "A". Attach the lower bracket

to the leaf stack using the 3/8"-16 x 3 1/2" carriage bolts (installed in

the lower bracket earlier), the flange lock nuts and bracket strap as

shown in Figure "A". Note that the lower bracket will sit on top of

the leaf spring with the bracket hook capturing the forward "U"-bolt.

The bracket strap is used to clamp the lower bracket to the leaf stack

see Figure "A".

S

TEP

4 - P

OSITION

THE

UPPER

BRACKET

ON

THE

FRAME

It is recommended that air pressure be added to the air spring at

this time to bring the upper bracket into position on the frame rail.

Cut a 6.00"-10.00" piece of air line tubing from the 18' roll . Install

one end into the elbow fitting located at the air spring, then place

one inflation valve on the other end of the air line (refer to step 9

for inflation valve installation). Once completed inflate the air

spring slowly (Do NOT inflate beyond 10 psi for this step). The

upper bracket will move upwards and fall into position on the

frame.

The portion of the upper bracket that is placed under the frame will rest against the bottom of the frame

rail on 4x2 vehicles. 4x4 vehicles must have at least 1/2" between the upper bracket and the under side

of the frame rail at the lowest point on the frame (Suggestion: use a 1/2" bracket strap included in the kit

between the upper bracket and the under side of the frame rail) see Figure "A". Note that the frame rail

is curved where the upper bracket is located, make sure there is a 1/2" of clearance between the upper

bracket and the lowest point on the frame see Figure "A".

S

TEP

5 - M

ARK

AND

DRILL

HOLES

IN

THE

FRAME

RAIL

Make sure the upper and lower brackets are parallel. With the air spring assembly in place, mark the

four holes to be drilled in the frame rail with a center punch. Drill the holes using a 3/8" drill bit. Before

drilling the holes make sure all electrical, brake and fuel lines are cleared from the path of the drill. In order

to prevent any damage to these lines it is recommended that a piece of wood be placed between the frame rail

and the existing lines while drilling.

NOTE:

Once the air helper springs

are installed, it is recommended that

the vehicle not be lifted by the frame,

as over-extension may occur, re-

sulting in damage to the air helper

springs. However, should it be-

come necessary to raise the vehicle

by the frame, deflate both air helper

springs completely.