Rite-Ride 1004 User Manual

Page 3

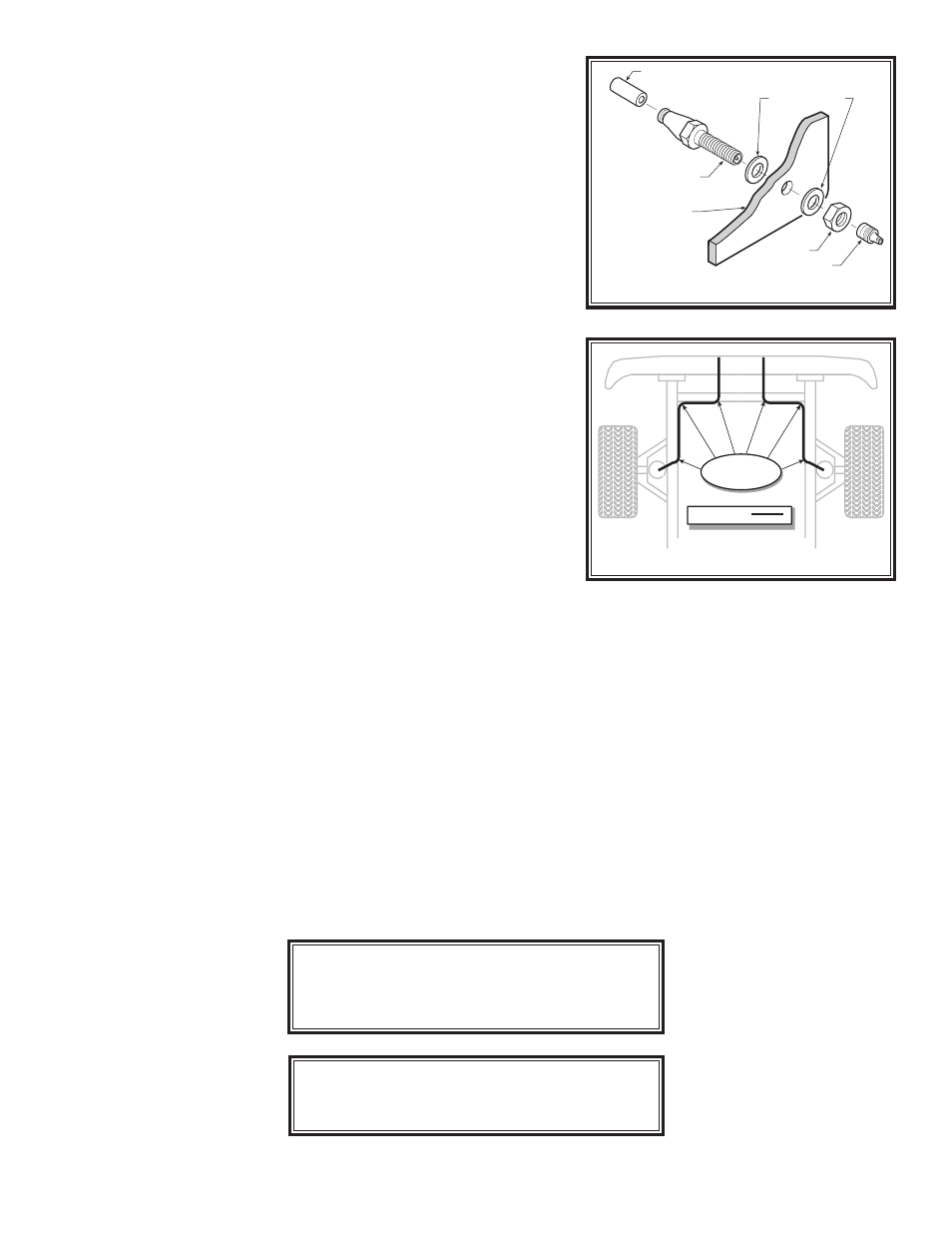

STEP 3—INSTALLING THE AIR LINE AND

INFLATION VALVE

Uncoil the air line tubing and cut it into two equal lengths.

DO NOT

FOLD OR KINK THE TUBING. Try to make the cut as square as pos-

sible. Insert one end of the tubing into the straight fitting installed into

the Level-Rite. Push the tubing into the fitting as far as possible,

see

Figure “B”.

Select a location on the vehicle for the air inflation valves. The loca-

tion can be on the bumper or the body of the vehicle, as long as it is

in a protected location so the valve will not be damaged, but maintain

accessibility for the air chuck,

see Figure “C”. Drill a 5/16" hole and

install the air inflation valve using two 5/16" flat washers per valve as

supports,

see Figure “C”. Run the tubing from the air helper spring to

the inflation valve, routing it to avoid direct heat from the engine, exhaust

pipe, and away from sharp edges. Thermal sleeves have been provided

for these conditions. If a thermal sleeve is required simply slide the

sleeve over the air line tubing to the location requiring protection. The

air line tubing should not be bent or curved sharply as it may buckle.

Secure the tubing in place with the nylon ties provided. Push the end of

the air line tubing into the inflation valve as illustrated,

see Figure “C”.

STEP 4— CHECK THE SYSTEM

Once the inflation valves are installed inflate the Air Over shocks to

70

psi and check the fittings for air leaks with an applied solution of soap

and water. If a leak is detected at a tubing connection then check to

make sure that the tube is cut as square as possible and that it is pushed

completely into the fitting. The tubing can easily be removed from the

fittings by pushing the collar towards the body of the fitting and then

pulling out the tube. If a leak is detected where the brass fitting screws

into the shock, remove the tubing by pushing the collar towards the body

of the fitting and then pulling out the tube, then screw the brass fitting

into the shock one additional turn. Reinstall the tubing and re-inflate

the air springs and check for leaks as noted above.

This now completes the installation. Install the wheels and torque

the lug nuts to the manufactures specifications. Raise the front of the

vehicle, remove the jack stands, and lower the vehicle back onto the

ground.

FOR BEST RIDE use only enough air pressure in the air helper

springs to level the vehicle when viewed from the side (front to rear).

This amount will vary depending on the load, location of load, condition

of existing suspension and personal preference.

AIR LINE

PUSH-TO-CONNECT

INFLATION VALVE

FLAT WASHER

HEX NUT

VALVE CAP

BODY OF

VEHICLE

Figure “B”

Figure “C”

NOTE:

MIN PRESSURE

10 PSI

MAX PRESSURE (LOADED)

100 PSI

NOTE:

DO NOT remove the air spring

assembly from the shock. This will cause

damage to the product and void the warranty.

NYLON TIES

AIR LINE