Rite-Ride 2560 User Manual

Page 4

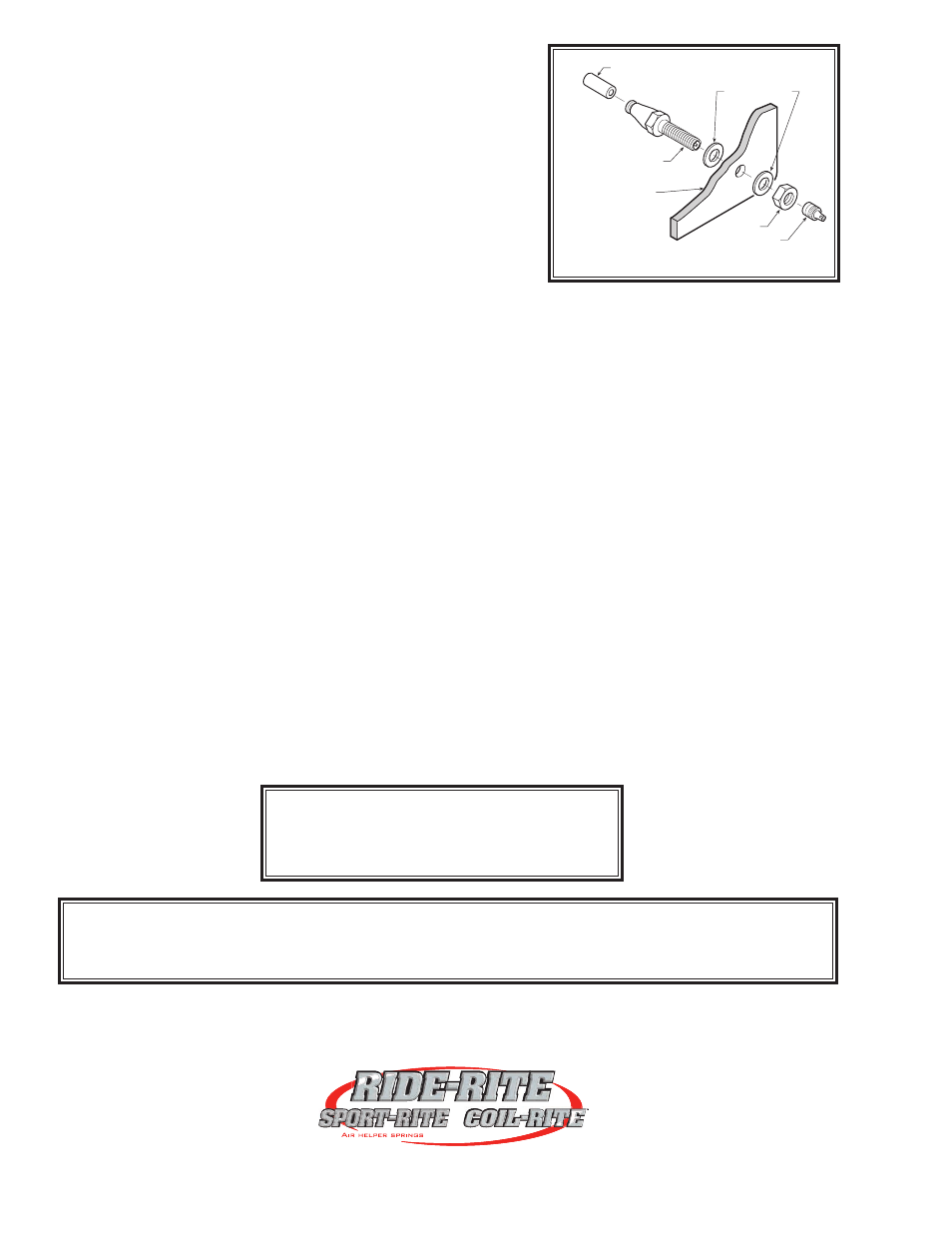

engine, exhaust pipe, and away from sharp edges. Thermal sleeves

have been provided for these conditions. The airline tubing should not

be bent or curved sharply as it may buckle. Secure the airline tubing

in place with the nylon ties provided. Push the end of the airline tubing

into the inflation valve as illustrated, see Figure “E”.

STEP 7— CHECK THE AIR SYSTEM

Once the inflation valves are installed, inflate the air helper springs to

70 psi and check the fittings for air leaks. Using a spray bottle, apply

a solution of soap and water to the fittings. If a leak is detected at an

airline tubing connection then check to make sure that the airline tube

is cut as square as possible and that it is pushed completely into the

fitting. The airline tubing can easily be removed from the fittings by

exhausting all the pressure in the air springs and then pushing the

collar towards the body of the fitting and then, with a pull, remove the

airline tubing. Re-install the tubing and reinflate the air springs and

check for leaks as noted above. If a leak is detected where the air fit-

ting screws into the spring, just screw the air fitting into the air spring

until the leak stops.

This now completes the installation. Reattach the negative bat-

tery cable and remove the wheel chocks from the front wheels. Before

proceeding, check once again to be sure you have proper clearance

around the air springs. With a load on your vehicle and the air helper

springs inflated, you must have at least 1/2" clearance around the air

springs. As a general rule, the air helper springs will support approxi-

mately 50 lbs. of load for each psi of inflation pressure (per pair). For

example, 50 psi of inflation pressure will support a load of 2500 lbs.

per pair of air helper springs.

FOR BEST RIDE use only enough air

pressure in the air helper springs to level the vehicle when viewed

from the side (front to rear). This amount will vary depending on the

load, location of load, condition of existing suspension and personal

preference.

NOTE: Too much air pressure in the air helper springs will result in a

firmer ride, while too little air pressure will allow the air helper spring

to bottom out over rough conditions. Too little air pressure will not

provide the improvement in handling that is possible. TO PREVENT

POSSIBLE DAMAGE MAINTAIN A MINIMUM OF 5 psi IN THE AIR

HELPER SPRINGS AT ALL TIMES.

NOTE:

Once the air helper springs are installed, it is recommended that the vehicle not be lifted by

the frame, as over-extension may occur, resulting in damage to the air helper springs. However, should

it become necessary to raise the vehicle by the frame, deflate both air helper springs completely.

www.ride-rite.com

NOTE:

MIN PRESSURE

5 PSI

MAX PRESSURE (LOADED)

100 PSI

FIGURE “E”

AIR LINE

PUSH-TO-CONNECT

INFLATION VALVE

FLAT WASHER

HEX NUT

VALVE CAP

BODY OF

VEHICLE

(Step 6)