1 technical data, 1technical data, Series pa/f, pa/s – Richter PA/S Series Sampling Valves User Manual

Page 3

Series PA/F, PA/S

Page 3

9510-060-en

Revision 02

TM 7165

Edition 06/2008

1

Technical Data

Manufacturer:

Richter Chemie-Technik GmbH

Otto-Schott-Str. 2

D-47906 Kempen

Telephone: +49 (0) 2152 146-0

Fax:

+49 (0) 2152 146-190

E-Mail:

Internet:

Designation :

Series

PA/F

plastic lined, lever can be removed

PA/S

Stainless steel version, without lining, lever

can be removed

PAP/F

Option, prepared for pneumatic, hydraulic.

PAP/S

or elecectric actuator to ISO 5211

Certified to Clean Air Act (TA-Luft)

Strength and tightness (P10, P11) of the pressure-

bearing body tested to DIN EN 12266-1.

Gas-tight (P12) in the seat to DIN EN 12266-1,

leak rate A

Face to face:

DIN EN 558-1 basic series 1, ISO 5752 series 1

Flange connecting dimensions:

DIN EN 1092-2, type B (ISO 7005-2, type B) PN 16

or flanges drilled to ASME 16.5, Class 150

Materials :

Body material: Ductile cast iron EN-JS 1049 to DIN EN

1563 (0.7043 DIN 1693) or investment cast stainless

steel

Lining material: PFA/PTFE .../F

On request:

antistatic

…/F-L

highly permeation-resistant …/F-P

Temperature range :

- 60 °C to + 200 °C

See pressure-temperature diagram in Section 1.4.

Operating pressure:

from vacuum to max. 16 bar

See pressure-temperature diagram in Section 1.4.

Nom. sizes :

PA/F, PAP/F

DN 25, 40, 50

PA/S, PAP/S DN 25, 50

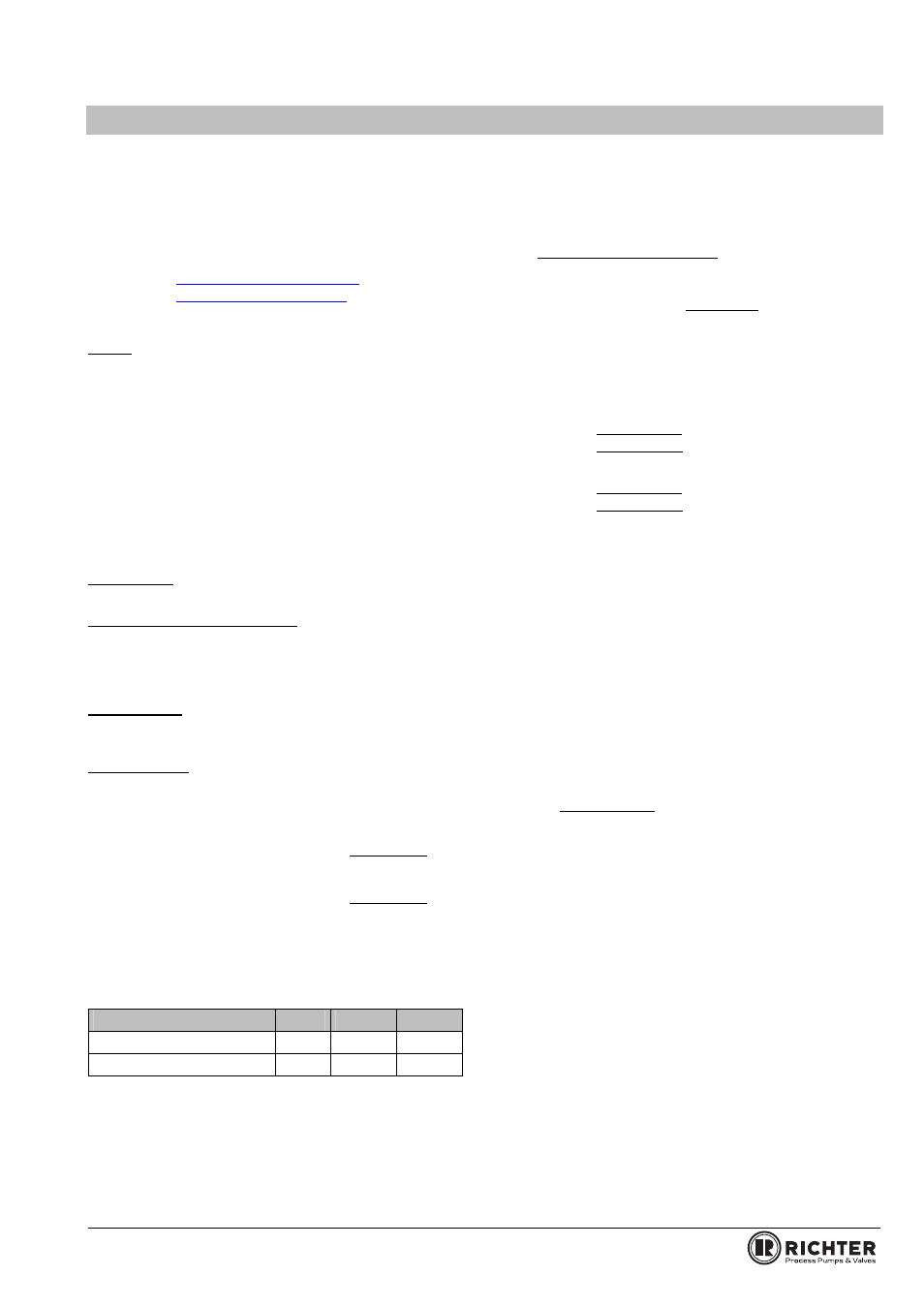

Weights:

ca. kg

Nom. size

25

40

50

PA/F (manually actuated)

10 18 18

PA/S (manually actuated)

9

--- 14

Installation position :

The installation position is normally horizontal with the

bottle connection vertically downwards (deviations

from this position require a special bottle connection).

See Section 6.2, 10.4 und 10.9.

Dimensions and individual parts:

See sectional drawings in Section 10.

Options :

Design for highly viscous media or applications

with a low a low operating pressure.

The special flat plug produces a full cross section

of the outlet opening of 10 mm at a travel of 3 mm.

PA/F see Section 10.5

PA/S see Section 10.8

Adapter for vertical valve installation

PA/F see Section 10.4

PA/S see Section 10.9

Sampling valve with lever locking

9510-00-0005

Adapter for bottle holder, discharge spout

PA/F

9510-00-0012

Sampling valve with protective cabinet

PA/F

9510-00-0011

PA/S

9510-00-0014

Sampling valve with protective cabinet and

handwheel

PA/S

9510-00-0015

Sampling valve with handwheel

PA/F

9510-00-0017

PA/S

9510-00-0016

Sampling valve with actuator

See Section 10.10

Adapter for sampling bottles

Adapter prepared for final preparation by the

customer

Adapter for small bottles with centering

Sampling valve with septum bottle

PA/F

9510-00-0018

Sampling valve with heating jacket

PA/S

9510-00-0019