7 operation, 1 initial commissioning, 2 improper operation and their consequences – Richter PA/S Series Sampling Valves User Manual

Page 10: 3 sampling (standard), 4 shutdown, Initial commissioning, Sampling (standard), Shutdown, 7operation, Series pa/f, pa/s

Series PA/F, PA/S

Page 10

9510-060-en

Revision 02

TM 7165

Edition 06/2008

7

Operation

7.1 Initial

commissioning

Normally, the ball valves have been tested

for leaks with air or water. Prior to initial

operation check body bolting. For torques

see Section 1.2.

Unless otherwise agreed, there could be residual

amounts of water in the flow section of the ball valve;

this could result in a possible reaction with the

medium.

To prevent leaks, all connection screws should be

retightened after the initial loading of the valve with

operating pressure and operating temperature.

For torques see Section 1.2.

7.2 Improper operation and their

consequences

Crystallisation may result in damage to the seat

rings or ball/stem unit. This can be prevented by

heating.

In extreme cases a leak may occur.

Increased wear occurs when the valve is operated

with solid contents.

Violent opening or rapid filling may cause the bottle

to burst.

Non-observance of the pressure-temperature

diagram may result in damage.

Do not transport the valve using the lever.

Do not use a lever extension as otherwise there is

a risk of damage.

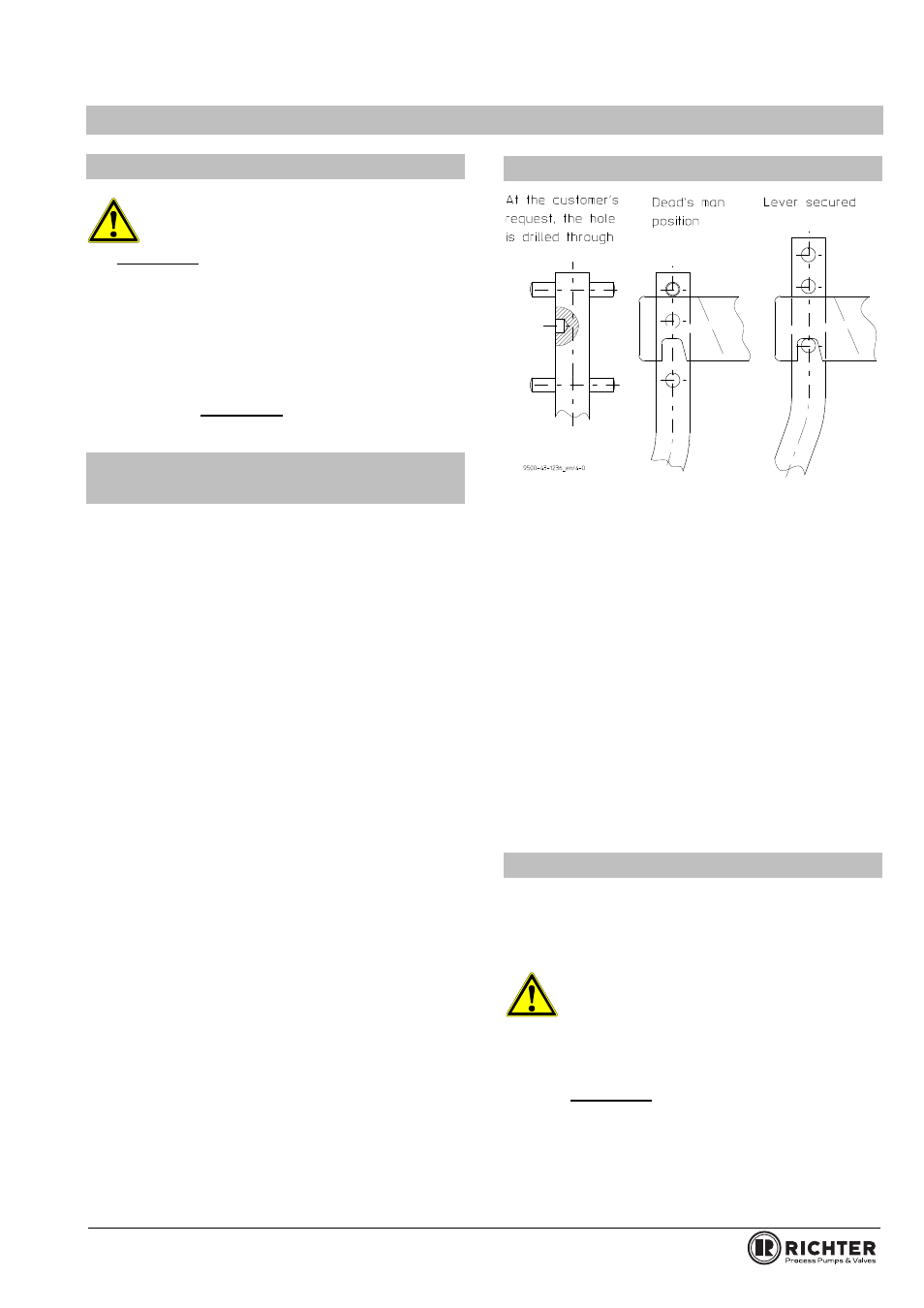

At the customer's request, the middle hole in the

lever is drilled through. If the lever is then locked

in the lower hole to take samples and if, in addi-

tion, a pin is inserted into the middle hole, it must

be ensured that sampling does not take place

accidentally.

7.3 Sampling

(standard)

Screw bottle into the bottle connection 226.

Check travel set on the star knob 963/1.

Lever 203 is in the dead man's position.

For sampling, lock lever in the top groove.

If it is requested that the lever is firmly locked, drill

through the middle hole and insert an additional pin

into the middle hole.

CAUTION! Sampling may also take place acciden-

tally.

Press in direction of valve.

Sampling can take place.

A lock is available from Richter as an option.

A device for the risk-free discharge of the medium

must be connected to the venting connection.

Sealing plugs are inadmissible as overpressure occurs

in the bottle.

7.4 Shutdown

The local regulations are to be observed when

dismantling the valve.

Prior to undoing the flange connection ensure, that the

plant is depressurised and emptied.

Prior to starting any repair work, the valve is

to be thoroughly cleaned. Even if the valve

has been properly emptied and rinsed,

residual medium may still be found in the valve.

After dismantling, immediately protect the valve

flanges against mechanical damage with flange caps.

See also Section 5.1.