5 maintenance, 1 external, single mechanical seal, 1 dismantling – Richter Mechanical Seals User Manual

Page 5: 5maintenance, Series sck

Series SCK,

mechanical seal, external, single

Page 5

single with double lip seal on the wetted side

single with lip seal on the atmosphere side, with quench

9220-060-en Revision 10

TM 7827

Edition 03/2010

5

Maintenance

The regulations of the mechanical seal

manufacturer must always be observed.

See also the installation and operating manual

for the SCK series.

In normal operations this seal should not drip. The

leak should only be so minimal that it evaporates

immediately.

It is advisable to check the attachment screws of the

mating ring adapter 487 and of the rotating unit 470/2

for a tight fit from time to time.

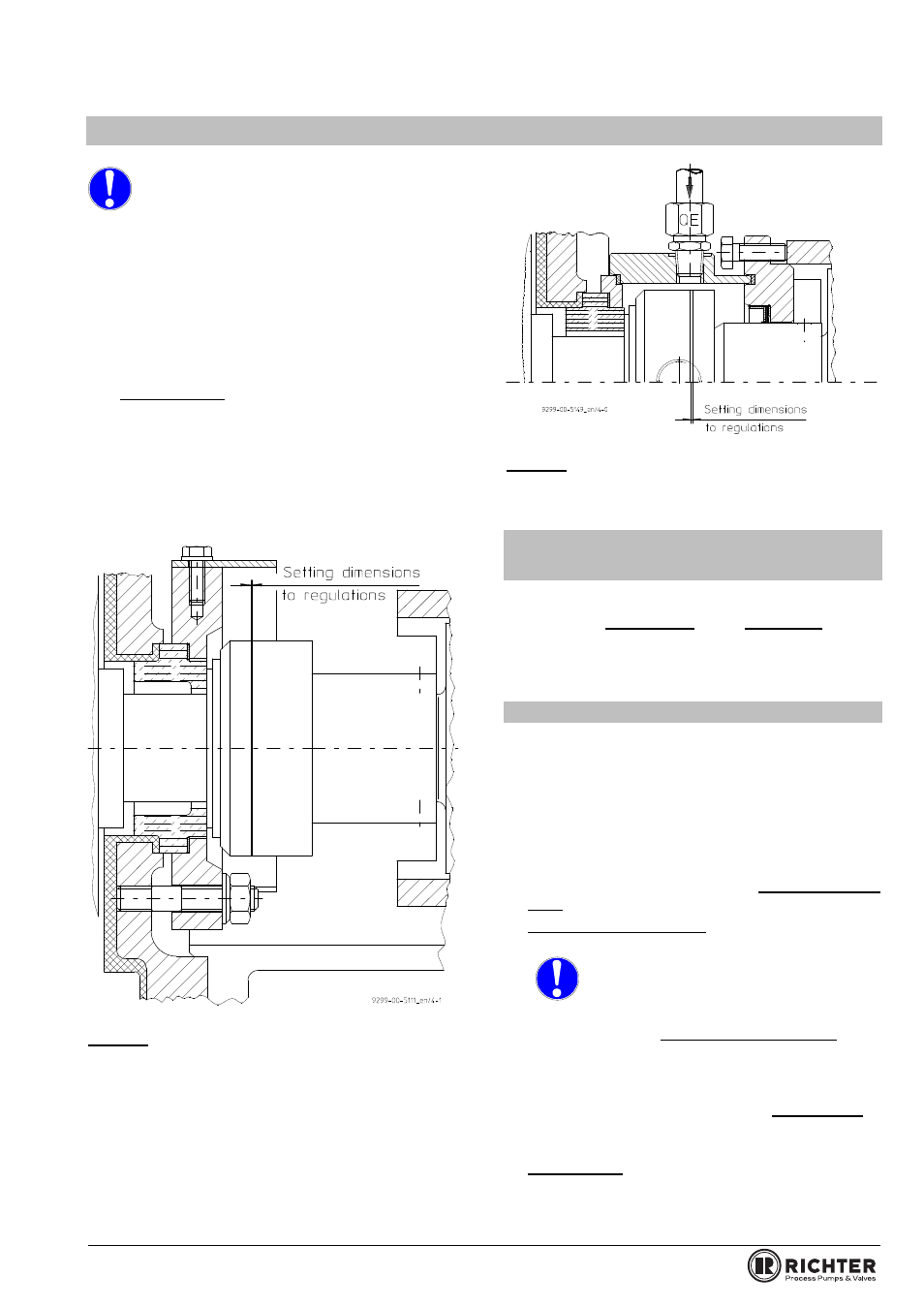

The wear on the rotary ring can be readily seen by the

increased size of the set dimension in many makes.

See Figure 1 and 2.

The external mechanical seals are to be replaced

before the wear on the rotary ring become so great

that the pressing forces are no longer sufficient

as a result major leaks occur.

Often marks on the mechanical seal indicate the

admissible wear.

Figure 1 External, single mechanical seal with

and without lip seal

Figure 2 Single mechanical seal with lip seal

and quench

5.1 External, single mechanical

seal

Dismantling can be checked using the sectional

drawings in Section 7.2 and Section 9 in the

installation and operating manual SCK, also the

available components.

5.1.1 Dismantling

Remove seal guard 685.

Undo setscrews 904/1 of the distance bush 543.

Undo attachment screws of the rotating unit 470/2.

Undo screws of bearing pedestal 330 / back plate

161

and, with the mating ring 475/1 and the mating

ring adapter 487 still mounted, move up to the

impeller with light hammer blows (plastic hammer).

For design of back plate, see Section 4.2 and

7.7.4

in the installation and operating manual SCK.

Bearing pedestal group 3:

Labyrinth disc 555 must be secured with two bolts

prior to the dismantling

of the impeller.

For this purpose there are 2 bores Ø5mm

in the bearing pedestal. The double

mechanical seal is relieved of pressure as a result.

See dismantling in Sections 7.7.1 and 7.7.5 in the

installation and operating manual SCK.

Undo impeller 230 with a strap wrench or

assembly wrench. Right-hand thread.

For assembly aid for impeller, see Section 10.1 in

the installation and operating manual SCK.

See also installation and operating manual SCK,

Section 7.7.1

.

Unscrew the impeller 230 completely.