2 tightening torques, 3 type plate, 2 safety, transport, storage and disposal – Richter SCK-S User Manual

Page 5: 3 product description, 1 mode of operation, Tightening torques, Type plate, Mode of operation, 3product description, Series mnk-s, mnk-sb, sck-s

Series MNK-S, MNK-SB, SCK-S,

“Self-priming“ design

Page 5

9230-062-en

Revision 02

TM 6566

Edition 08/2006

1.2 Tightening torques

Screws lubricated, tighten in diametrically opposite

sequence

Volute housing hex. screws 901/22

No. x size

Nm

24 x M 10

40

Feed elbow hex. screws 901/20

No. x size

Nm

8 x M 12 40

Draining cover hex. screws 901/21

No. x size

Nm

8 x M 10 20

Blind cover stud screws 902/1

No. x size

Nm

8 x M 10 20

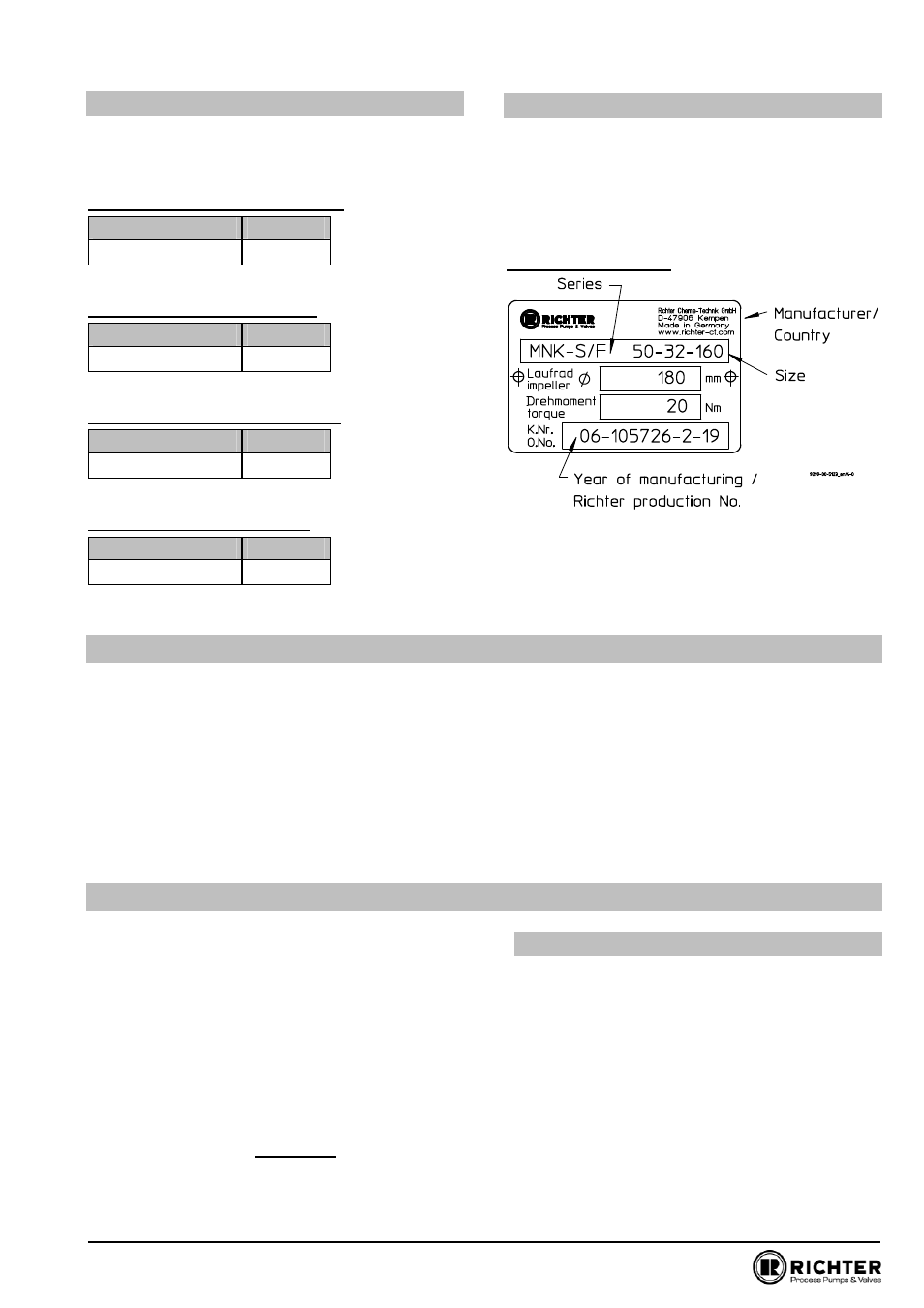

1.3 Type plate

The stainless steel type plate is firmly riveted to the

housing:

If the operator attaches his identification, it must be

ensured that the pump matches the application in

question.

Example of type plate:

2 Safety, transport, storage and disposal

As regards safety, transport, storage and disposal, the

relevant chapters in the adjacent installation and op-

erating manuals apply.

This supplementary installation and operating

manual is only valid in conjunction with the following

installation and operating manuals, depending on the

design selected:

MNK

long-life grease lubrication

9230-050-en

MNK

oil bath lubrication

9230-051-en

MNK-B close-coupled design

9230-055-en

SCK

long-life grease lubrication

9220-050-en

SCK

oil bath lubrication

9220-055-en

3

Product description

In contrast to normal-priming centrifugal pumps, the

self-priming pump is able to vent its suction line itself.

It produces a vacuum in the suction line and so the

medium is drawn in until finally the entire suction line

is full and conveyance of the medium can commence.

Here, it must be ensured that the maximum geodetic

suction lift and the maximum geodetic back pres-

sure are not exceeded and that the vapour pressure

of the medium in the pump is not undershot during

the venting process.

The housing of the self-priming pump can be seen in

the sectional drawing in Section 8.1.

3.1 Mode of operation

Before it is switched on, the pump must be filled at

least up to the lower edge of the suction nozzle.

After the pump has been switched on, the liquid in

the feed elbow is conveyed by the impeller through

the volute housing into the pump housing.

Driven by the pressure generated by the impeller,

the medium is injected from here through the valve

seat back into the impeller again.

This jet of medium passes over the inlet openings of

the vanes of the rotating impeller and so air pockets

are produced by the medium in the vanes. The im-

peller vanes are thus flushed with medium, which is

why this venting principle is also called the impeller

vane flushing method.