8 maintenance, 9 electric peripheral equipment, 3 transport, storage and disposal – Richter MPB 25-25-115 User Manual

Page 8: Maintenance, Electric peripheral equipment, 3transport, storage and disposal, Series mpb, Close-coupled design

Series MPB,

close-coupled design

Page 8

9240-050-en

Revision 05

TM 7345

Edition 10/2008

Table 2

Limit values of the

temperature of the liquid

Temperature class

accord. EN 13463-1

PFA/PFA-L

T6

(85 °C)

75 °C

1)

T5 (100 °C)

90 °C

1)

T4 (135 °C)

125 °C

1)

T3 (200 °C)

150 °C

T2 (300 °C)

150 °C

T1 (450 °C)

150 °C

1) The limit values specified for the temperature of the medium at

the pump inlet are determined for the most unfavourable case

(high speed, low flow, low heat capacity of the medium, ....).

Under favourable operating conditions the limit values specified

may be increased by up to 5 K after consultation with the

manufacturer.

In the case of motors with the type of protection

"increased safety", no or low temperature entries are

generally permitted for the motor shaft and motor

flange related to an ambient temperature of 40 °C.

In these cases the max. admissible medium

temperature is 20 K above the temperature which may

be introduced into the motor.

e.g.: Max. motor shaft temperature: 60°C

Max. motor flange temperature: 65°C

This results in a maximum medium temperature for

the pump of 80 °C (60 °C + 20 K)..

2.6.8 Maintenance

For safe and reliable operation, it must be

ensured with regular inspection intervals that

the unit is properly serviced and kept in a

perfect technical condition.

If auxiliary systems (e.g. external flushing, cooling,

heating) are installed, a check must be made to see

whether monitoring facilities are required to safeguard

their operation.

2.6.9 Electric peripheral equipment

Electric

peripheral

equipment,

e.g.

pressure,

temperature and flow sensors etc. must comply with

the prevailing safety requirements and explosion

protection provisions.

Regular checks of the motor bearings in

accordance with the operating manual of the

motor manufacturer. Observe ATEX notes.

3

Transport, storage and disposal

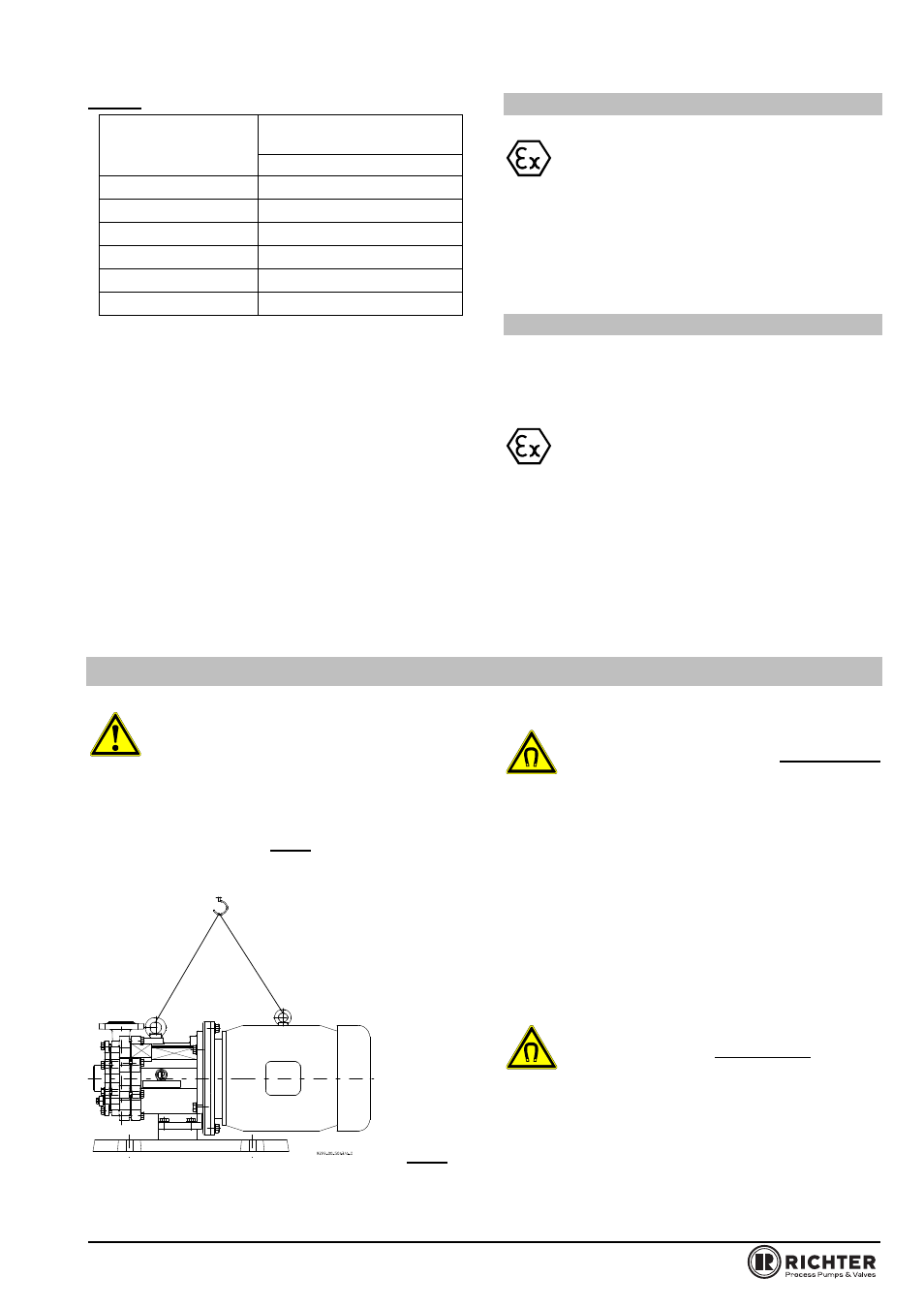

The pump or the unit must be transported

properly. It must be ensured that during

transport the pump/unit remains in the

horizontal position and does not slip out of the

transport suspension points.

The ring bolts of the pump and the motor must be

used to transport the entire unit, i.e. pump with

baseplate and motor. See Fig. 1.

The slinging ropes must not be attached to free shaft

ends.

Fig. 1

Directly after receipt of the goods, the

consignment must be checked for completeness

and any in-transit damage.

Damaged pumps must not be installed in the plant.

When unpacking magnetic drives as single

parts, the relevant notes in Section 7.5.2

must be observed.

Handle goods carefully to prevent damage.

Flange covers serve as protection during transport

and must not be removed.

If the unit is not installed immediately after delivery, it

must be put into proper storage.

The product should be stored in a dry and vibration-

free, well ventilated room at as constant a

temperature as possible.

Elastomers are to be protected against UV light.

In general, a storage period of 10 years should not be

exceeded. An admissible storage period of 4 years

applies to elastomers made of NBR.

If magnetic drives are stored as single parts,

the relevant notes in Section 7.5.2 are to be

observed.

In the case of prolonged storage conservation

agents on machined component surfaces and packing

with a desiccant may be necessary.