Grand conversion, 12 and 20 gauge – RCBS The Grand Conversion Unit User Manual

Page 4

GRAND CONVERSION

12 AND 20 GAUGE

Congratulations on your purchase of the RCBS Grand

conversion unit!

CONVERSION INSTRUCTIONS:

1. Please refer to your THE GRAND product instruction

manual.

2. Empty POWDER and SHOT hoppers. Section titled DRAIN

SHOT AND POWDER HOPPERS.

3. Empty remaining powder and shot in the charge bar.

Section titled SHOT AND POWDER CHARGE BUSHING

CHANGE, emptying charge bar for bushing change.

4. Remove SHOT and POWDER hoppers by removing the

10-24 Nyloc nut with a 3/8 wrench (not provided). Be

careful not to lose index ball and spring found under each

hopper base.

5. Remove charge bar by first pulling out the locking pin in

the upper right corner of the CHARGE BAR. Slide charge

bar to the right being careful not to allow the SHOT or

POWDER bushings to fall from the charge bar. Section

titled POWDER AND SHOT SYSTEM.

6. Install primer shut off pin and remove primer tray.

7. Remove index arm from base of press frame.

8. Disconnect lower push rod from upper push rod by loosening

1/4-28 nut with 7/16 wrench (not provided) and unscrewing

lower push rod from upper push rod (note: lower push rod

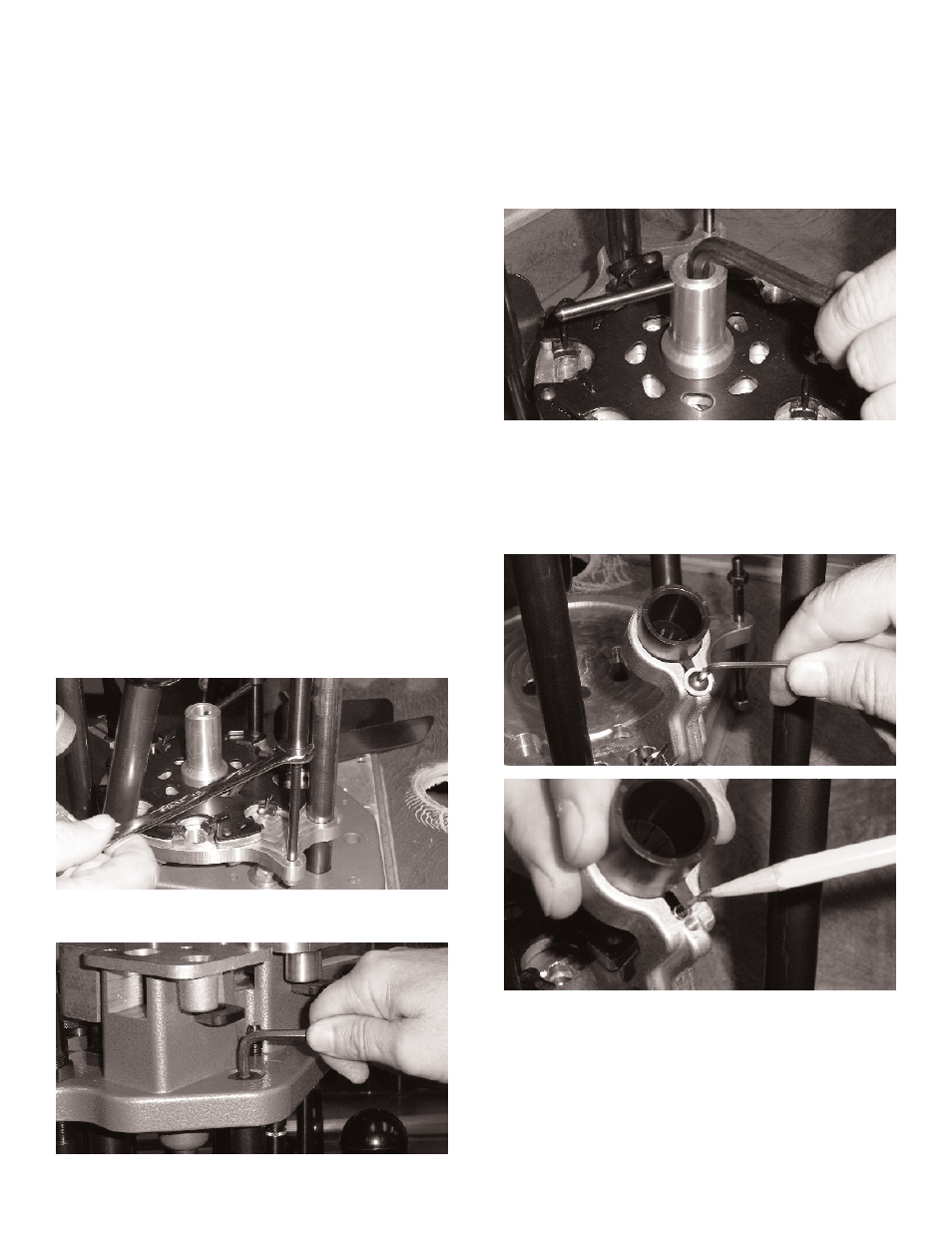

remains attached to base plate). (See photo 1)

9. Remove the three column support screws on the top of the

tool head using the 7/32 hex wrench provided. (See photo 2)

10. Lift off tool head and set aside.

11. Remove case eject assembly with 5/16 hex wrench

provided. (See photo 3)

12. Remove case holder plate assembly.

13. Replace wad guide by removing 8/32 cap screw and

washer, replace with appropriate wad guide, reinstall

washer and cap screw (note: three springs are below the

wad guide index tab in the upper wad guide assembly).

(See photos 4 & 5)

14. Clean shell plate holder of any debris, lube center shaft

and install new case holder plate assembly.

15. Install appropriate case eject assembly. Temporarily tighten

until tool head is replaced (CAUTION! Raising the shell

holder plate at this time, with the case eject assembly not

aligned, may result in damage to the dies in the upper tool

head).

3

3

4

5

1

2