Troubleshooting – GBC MS5 User Manual

Page 16

F.300-B/MS-5 DRILL/JULY 2000

16

WARNING: DISCONNECT THE POWER AND LOCK IT OUT whenever working on the machine

unless the instructions specifically require the machine to be powered (see Power Lockout

Procedure,

page 4

). Several of the following tests may require the machine to be operational

for checking and adjusting. Be very careful that tools and other people are clear of moving parts, and

that the drill is not accidentally operated while adjustments are being made.

CAUTION: Whenever repairing hydraulic components, loosen connections slowly to bleed

off any trapped pressure.

Problem

Area to Check

Solution

1. No power

Power to machine

Connect Power

Main Disconnect Switch

Turn to ON position

Interlocking Guards

Replace guards

Fuse blown

Replace fuse - see fig. 2

page 7

2. Lack of power

Relief valve in pump may be bad

Clean or replace relief valve or pump.

or have dirt in it.

Check oil level - may be low.

Add oil.

Check voltage at machine - may

Remove other machinery on line or

be low.

provide a dedicated line.

3. Spindle motor stalls

Dull drills.

Sharpen drills.

Check for low voltage.

(See above).

Check drive pulley and belt for

(See SETUP INSTRUCTIONS in main

tightness.

section for adjustment).

Check for paper plugging drills

Clean out hollow drills - We recom-

mend cleaning and soaking drills in

oil overnight.

4. Table stroke won’t adjust

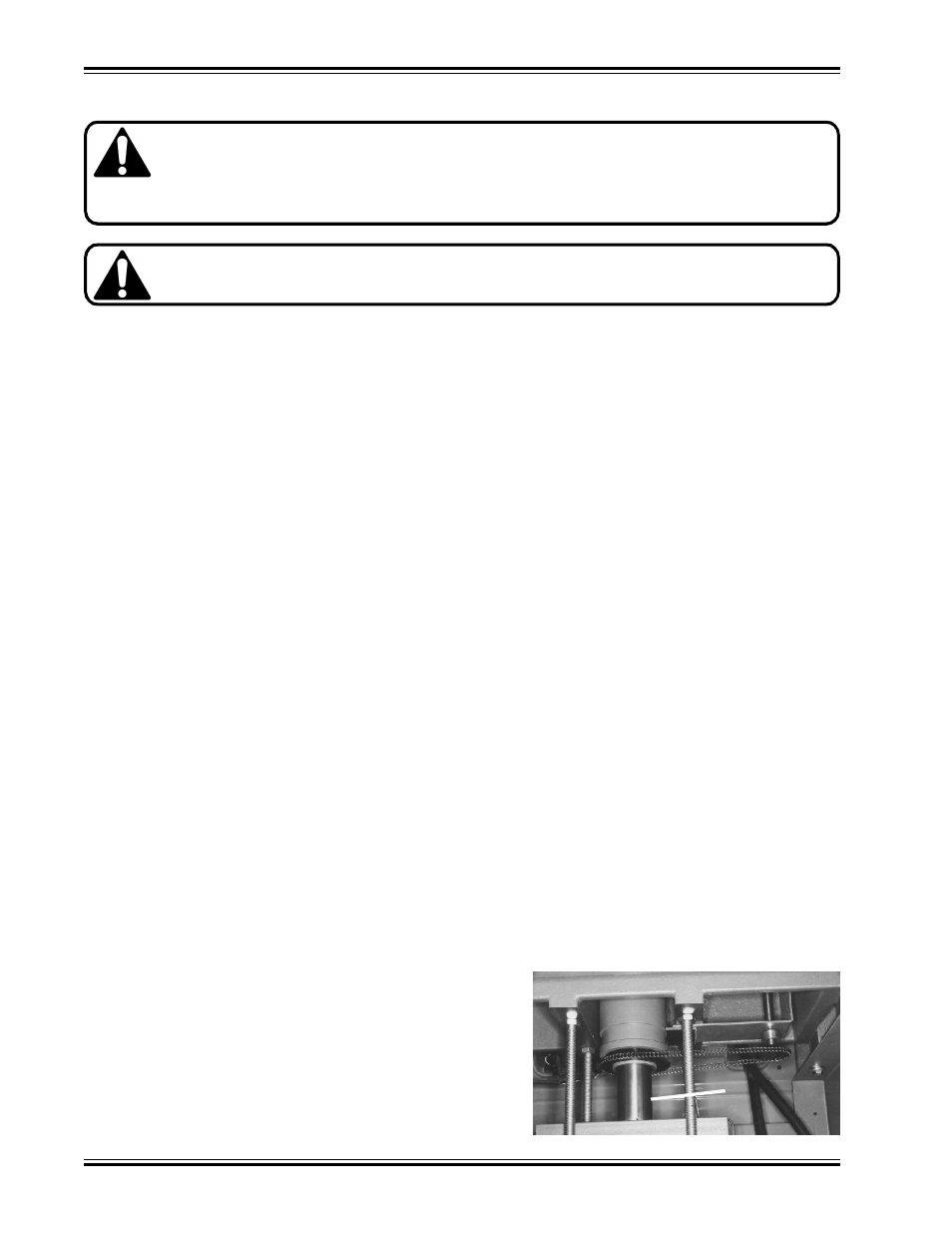

Stroke Adjustment Chain off

Remove back panel and replace

sprockets.

chain (fig. 10).

TROUBLESHOOTING

(fig. 10)

Table Lift Rod