Elev ator aileron rudder, As3x control direction test – E-flite Carbon-Z Splendor BNF Basic User Manual

Page 9

EN

Assemble the aircraft and bind your transmitter to the receiver

before performing this Test.

Activate the AS3X system by advancing the throttle to 25%, then

fully lowering the throttle.

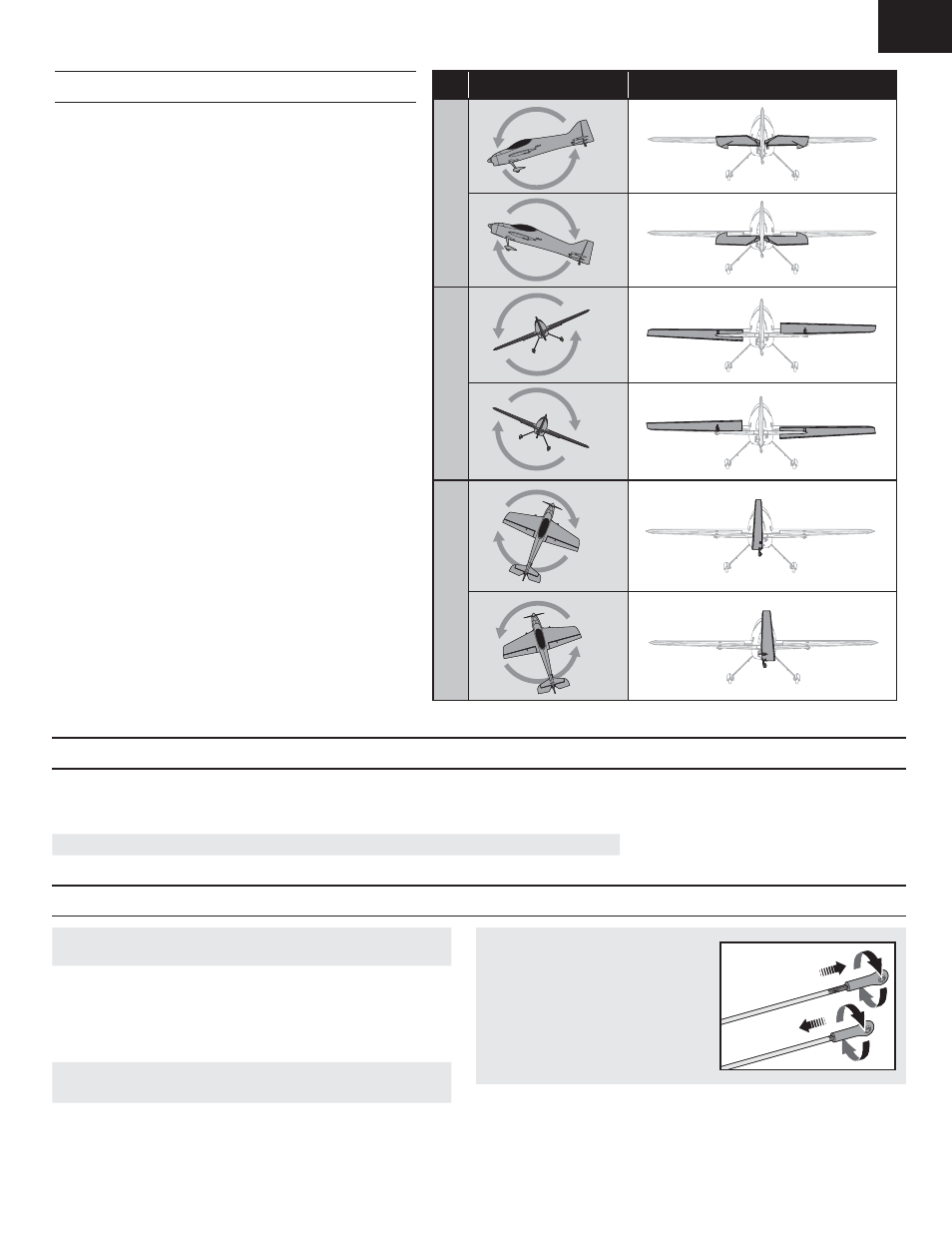

Move the aircraft as shown to ensure the AS3X system moves the

control surfaces in their proper direction. If the control surfaces do

not respond as shown, do not fly the aircraft. Refer to the receiver

manual for more information.

Once the AS3X system is active, the control surfaces may move

rapidly on the aircraft. This is normal. AS3X will remain active until

the battery is disconnected.

Aircraft movement

AS3X Reaction

Elev

ator

Aileron

Rudder

AS3X Control Direction Test

Move the controls on the transmitter to make sure the aircraft control surfaces move correctly and in the proper direction or reverse a servo. After performing the

Control Test, correctly set the failsafe. Make sure the transmitter controls are at neutral and the throttle and throttle trim are in the low position, then rebind the

model to your transmitter. If the receiver loses its connection to the transmitter, the failsafe will drive the servos to the settings made at binding.

NOTICE: In your transmiter, ensure Channel 5 servo is in NORMAL position for proper AS3X funcionality.

Control Direction Test

Control Surface Centering, Transmitter and Receiver Operation

IMPORTANT: Perform the Control Direction Test before performing control

surface centering.

Control Surface Centering and Adjusting a Linkage

Tip: While AS3X is inactive (before advancing the throttle), mechanically center

the control surfaces.

IMPORTANT: Correct operation of the AS3X system requires sub-trim and

trim at 0.

After binding a transmitter to the model receiver, set the trims and sub-trims to

0, ensure the servo arms are in the correct positions, then adjust the linkages

to center the control surfaces.

• Turn the linkage clockwise or counter-

clockwise until the contol surface is

entered.

• Attach the linkage to the servo arm or

control horn after adjustment.

Tip: If using more than 8 clicks of flight trim, mechanically adjust the linkage

so less trim is needed, or AS3X operation may be affected.

Tip: Use needle-nose pliers or ball link pliers (RV01005) to remove or install a

link on a control horn

.

9