Caution – Burnham Series 2B User Manual

Page 6

A. Allowable loss of pressure to assure a burner

manifold pressure of 3½" (8.9cm) water for natural

gas.

B. Supply of gas to be provided in cubic feet.

C. Length of piping and number of fittings.

D. Specific gravity of gas.

E. Correction factor for specific gravity.

9.

BOILER PIPING

CAUTION

Failure to properly pipe boiler may result in

improper operation and damage to boiler or

building.

A. CLEARANCES - hot water pipes do not require

clearance from combustible construction.

B. Install drain valve and safety relief valve as shown

in Figures 1 and 3. Note - Safety relief valve must

be in vertical position.

C. Pipe safety relief valve discharge to floor.

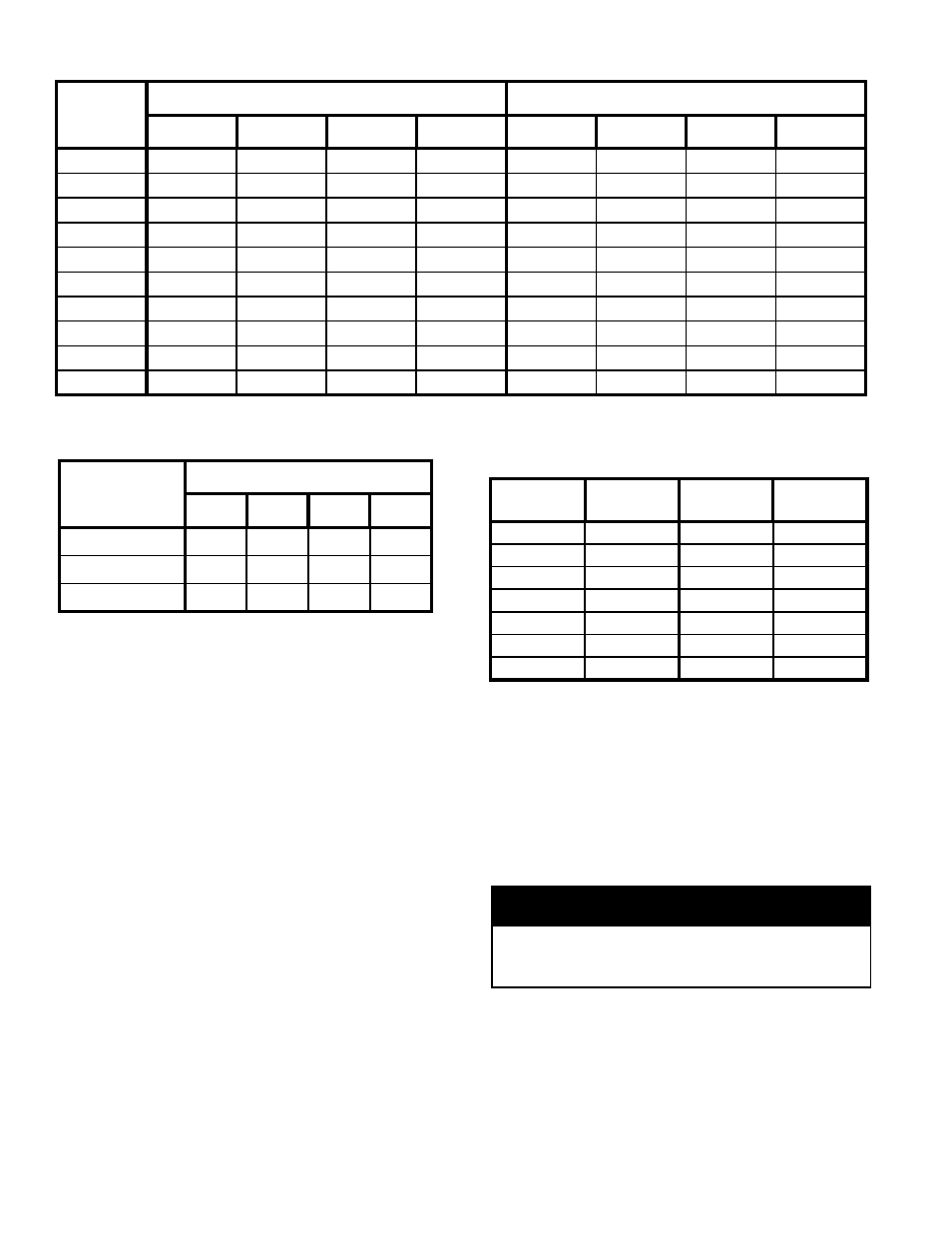

Table 1: Maximum Capacity of Schedule 0 Pipe in CFH For Natural Gas Pressures of ½ psig or Less

Table 2: Equivalent Length of Fittings

Table 3: Specific Gravity Correction Factors for

Natural Gas

This piping is to be supplied by the installer and must

include a trap, a ground joint union and a manual

shutoff valve upstream of the gas control assembly

outside of the jacket when codes require, see Figure 1.

A pipe thread compound resistant to the action of

liquefied petroleum gases should be applied to all

threaded joints in the gas piping. Pressure testing of the

Gas Supply Piping Boiler and its connections is

required before placing the boiler in operation.

The boiler and shutoff valve must be disconnected from

the gas supply piping system during any pressure

testing at pressures greater than ½ psig (3.5kPa).

The boiler must be isolated from the gas supply piping

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at pressures equal to or less than ½ psig

(3.5kPa).

RECOMMENDED SIZING OF GAS SUPPLY

PIPING TO BOILER FOR NATURAL GAS - shall

be such as to provide the required supply of gas without

undue loss of pressure between meter and the boiler.

Gas supply piping should be sized in accordance with

the Tables 1, 2 and 3. The following shall be taken into

account:

Length

[Feet]

0.3 Inch w.c. Pressure Drop

0.5 Inch w.c. Pressure Drop

½

¾

1

1¼

½

¾

1

1¼

10

132

278

520

1,050

175

360

680

1,400

20

92

190

350

730

120

250

465

950

30

73

152

285

590

97

200

375

770

40

63

130

245

500

82

170

320

660

50

56

115

215

440

73

151

285

580

60

50

105

195

400

66

138

260

530

70

46

96

180

370

61

125

240

490

80

43

90

170

350

57

118

220

460

90

40

84

160

320

53

110

205

430

100

38

79

150

305

50

103

195

400

Fitting

Nominal Pipe Size

½

¾

1

1¼

45° Ell

0.7

1

1.2

1.6

90° Ell

1.6

2.1

2.6

3.5

Tee (As Elbow)

3.1

4.1

5.2

6.9

Specific

Gravity

Correction

Factor

Specific

Gravity

Correction

Factor

0.50

1.10

1.30

1.07

0.55

1.04

1.40

1.04

0.60

1.00

1.50

1.00

0.65

0.96

1.60

0.97

0.70

0.93

1.70

0.94

0.75

0.90

---

---

0.80

0.87

---

---