Maintenance, Extension cords, Service – Bosch ROTOZIP RZ18V User Manual

Page 20: Cleaning, Warning, Caution

-20-

Service

NO USER SERVICEABLE

PARTS INSIDE. Preventive

maintenance performed by unauthorized

personnel may result in misplacing of

internal wires and components which

could cause serious hazard. We recom-

mend that all tool service be performed by a

Bosch Factory Service Center or Authorized

Bosch Service Station. SERVICEMEN:

Disconnect tool and/or charger from power

source before servicing.

BATTERIES

Be alert for battery packs that are nearing

their end of life. If you notice decreased

tool performance or significantly shorter

running time between charges then it is time

to replace the battery pack. Failure to do so

can cause the tool to operate improperly or

damage the charger.

Long term battery storage should be in

the discharged state. Battery packs last

longer and re-charge better when they are

stored discharged. Remember to fully re-

charge battery packs before using after

prolonged storage.

TOOL LUBRICATION

Your Bosch tool has been properly lubricated

and is ready for use.

CHUCK LUBRICATION

The wrenchless chuck has been properly

lubricated and is ready to use. If the chuck's

jaws begin to stick during use, the chuck

requires lubrication. To lubricate the chuck,

first remove debris from the inside of the

chuck with compressed air. Apply a pea-

sized amount of general-purpose grease to

the sides of the jaws, and adjust the chuck

through its full range of motion to distribute

the grease.

D.C. MOTORS

The motor in your tool has been engineered

for many hours of dependable service. To

maintain peak efficiency of the motor, we

recommend it be examined every six

months. Only a genuine Bosch replacement

motor specially designed for your tool should

be used.

BEARINGS

Bearings which become noisy (due to heavy

load or very abrasive material cutting) should

be replaced at once to avoid overheating and

motor failure.

Cleaning

To avoid accidents, always

disconnect the tool and/or

charger from the power supply before

cleaning. The tool may be cleaned most

effectively with compressed dry air. Always

wear safety goggles when cleaning tools

with compressed air.

Ventilation openings and switch levers must be

kept clean and free of foreign matter. Do not

attempt to clean by inserting pointed objects

through opening.

Certain cleaning agents and

solvents damage plastic

parts. Some of these are: gasoline, carbon

tetrachloride, chlorinated cleaning solvents,

ammonia and household detergents that

contain ammonia.

!

WARNING

!

WARNING

Maintenance

!

CAUTION

If an extension cord is

necessary, a cord with

adequate size conductors that is capable

of carrying the current necessary for your

tool must be used. This will prevent

excessive voltage drop, loss of power or

overheating. Grounded tools must use 3-

wire extension cords that have 3-prong plugs

and receptacles.

NOTE: The smaller the gauge number, the

heavier the cord.

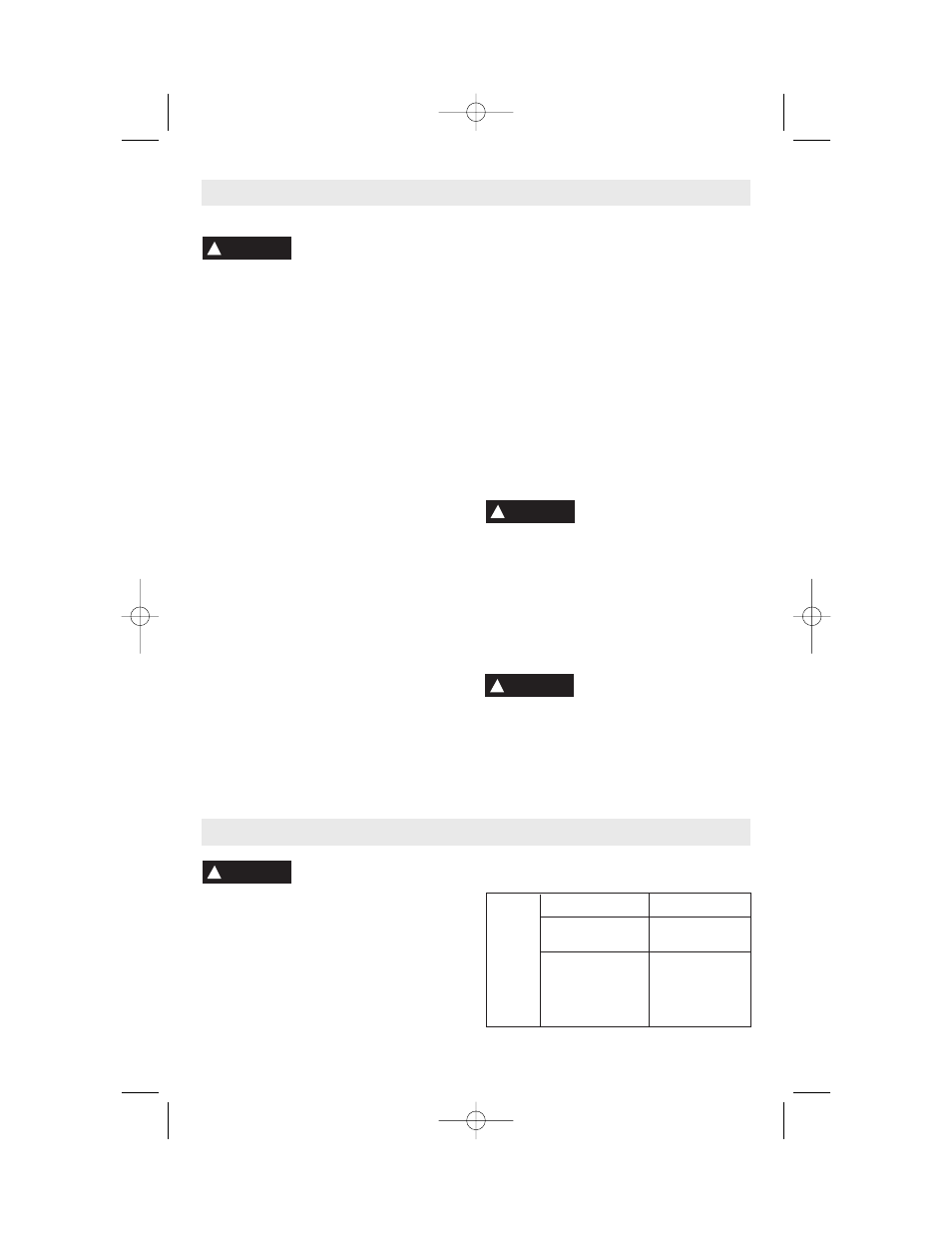

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

!

WARNING

Tool’s

Ampere

Rating

Cord Size in A.W.G.

Wire Sizes in mm

2

3-6

6-8

8-10

10-12

12-16

18

16

16

14

0.75 0.75 1.5

2.5

18

16

14

12

0.75 1.0

2.5

4.0

18

16

14

12

0.75 1.0

2.5

4.0

16

16

14

12

1.0

2.5

4.0

—

14

12

—

—

—

—

—

—

25

50

100 150

15

30

60

120

Cord Length in Feet

Cord Length in Meters

Extension Cords

RZ 2610925600 9-05 9/1/05 11:04 AM Page 20