Ii. installation, A. setup, B. installation overview – Watts PWBWIRONZ User Manual

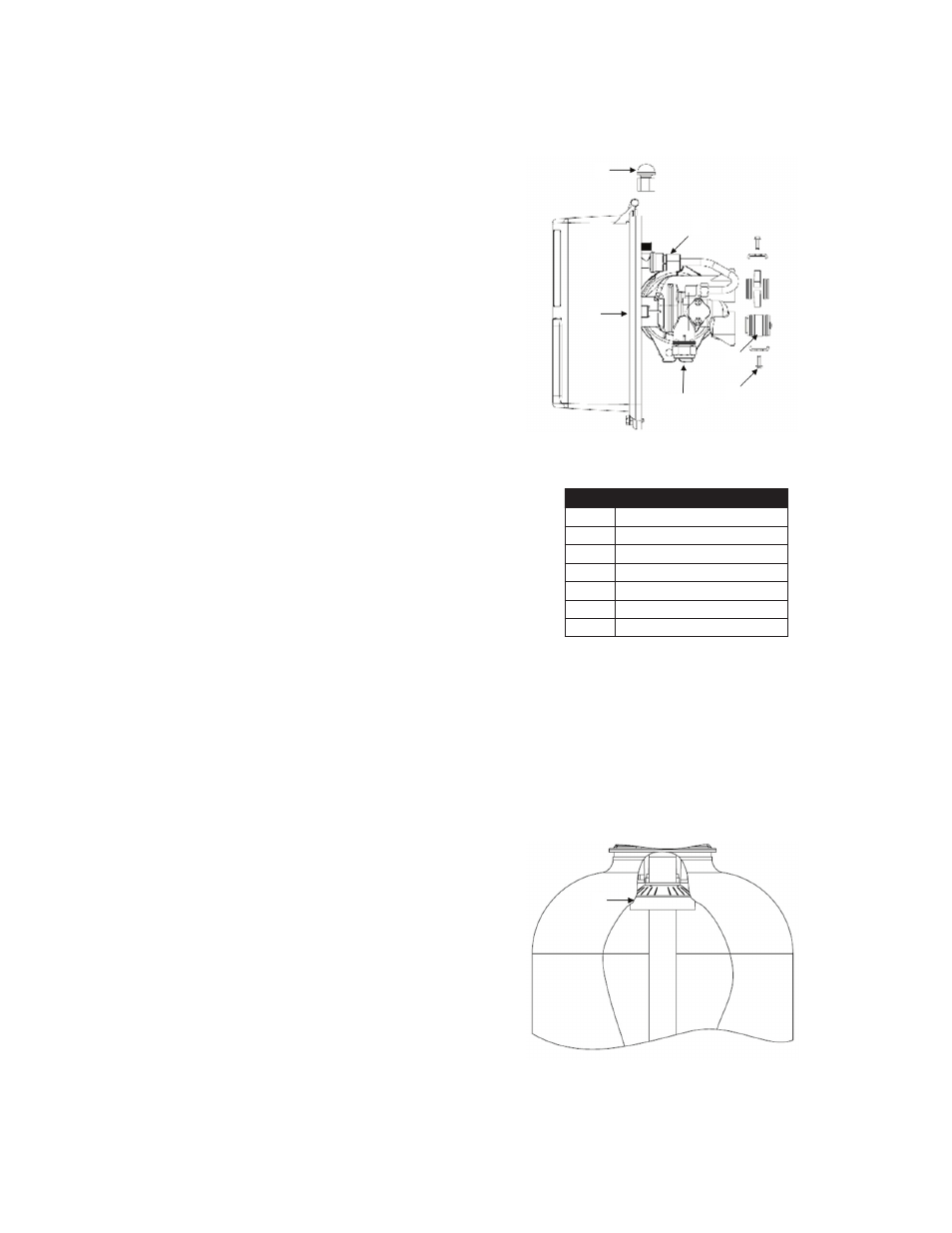

Page 4: C. 2510 aio control valve component identification, D. deflector installation

4

II. Installation

A. Setup

Unpack and check the system components for damaged or miss-

ing parts. Make sure that the bypass valve and plumbing yoke are

properly connected to each other and to the control valve with the

mounting clips. Make certain that the drain line flow control fitting

is installed properly on the drain port of the control valve. Systems

that are 13" in diameter and larger are not loaded with media. These

systems must be loaded with media before placing into service. To

load a system follow the below steps.

1. Cap the top open end of the distributor tube with tape and plas-

tic sheeting to keep foreign debris from entering the distributor

tube. This cap must be secure and not come off during media

loading.

2. Place the distributor tube, screen end down, into the mineral

tank and center it in the bottom. The top of the distributor tube

should be flush with the top of the tank.

3. Make sure the plastic and tape cap is secure to the top of the

distributor tube, place a funnel on the top of the tank and load

first the gravel then the Micro Z

®

media into the tank. The cap

must not come off of the distributor tube during the loading of

the media.

4. Remove the plastic cap from the distributor tube. DO NOT PULL

UP ON THE DISTRIBUTOR TUBE when removing the cap. The

distributor tube top must remain flush with the top of the tank.

5. Clean any media from the threads and top of the mineral tank

and install the deflector disk. See D. Deflector Installation section

for more details.

6. Lubricate the O-rings on the bottom of the control valve (dis-

tributor pilot O-ring and top of tank O-ring). Use non-petroleum

based silicone lubricant only.

7. Place the control valve on top of the tank. When doing this step,

seat the top of the distributor tube inside the centered O-ring

sealed port on the bottom of the valve first then press the valve

down until the tank threads come in contact with the valve

threads. This ensures that the distributor tube is properly seated

into the bottom of the control valve. Thread the valve on to the

tank clockwise. Be careful not to cross thread the valve or over

tighten it. A hand tight snug fit is appropriate for the control valve

torque. A wrench is not necessary. Do not use thread sealant or

PTFE tape on the threads.

8. The system is now ready for installation.

B. Installation Overview

Install the system after the supply lines to the outside faucets. This

system should be installed before a water softener or any taste/odor

cartridges, if applicable.

Ensure the inlet check valve item #5 is connected as shown in

Figure 2 to the inlet side of the 2510 AIO valve. The drain should be

installed in accordance with plumbing codes. Due to the release of

air during regeneration, the drain line should be anchored throughout

the run, secured at the end of the drain line, and properly vented.

The drain line should be sized for the backwash rate listed under

Drain Requirements taking into account friction loss.

C. 2510 AIO Control Valve Component

Identification:

Figure 3

D. Deflector Installation

Put a thin layer of silicone lubricant around inside diameter of the

deflector #7. Slowly slide the deflector over the distributor tube down

about 1". When threading the AIO valve to the tank, the bottom of

the threads will slide the deflector down. As shown in Figure 3.

Figure 2

ITEM

DESCRIPTION

1

2510 AIO CONTROL VALVE

2

VALVE COVER

3

CHECK VALVE, AIR DRAW VALVE

4

SCREEN, AIR CHECK ADAPTOR

5

INLET CHECK VALVE

6

SCREW, 8-32, SS, 2510AIO

7

DEFLECTOR DISK

6

5

3

4

2

1

Drain

7