Trained service technician’s regular maintenance, Caution, Nozzle installation – Beckett NX User Manual

Page 12: Figure 6. – electrode tip gap and spacing, Check/adjust electrodes, Protect nozzle from damage, Page 12, Nozzle flow rate by size

Page 12

RWB 6104 BNX R02

Nozzle Installation

•

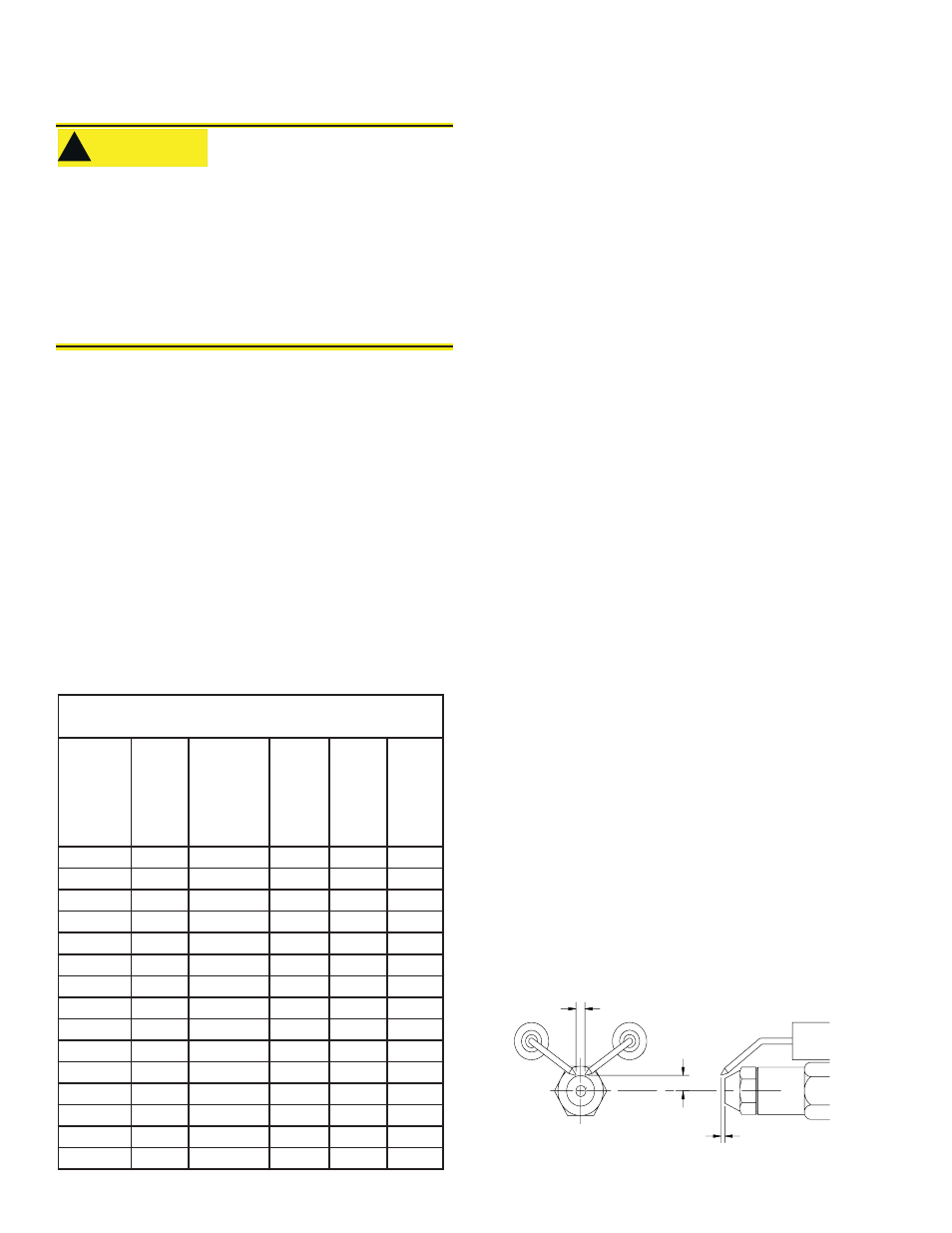

Nozzle fl ow rate U. S. gallons per hour of No. 2 fuel oil when

pump pressure (psig) is:

Nozzle

size

(rated

at 100

psig)

125

psi

140 psi

(factory

std.)

150

psi

175

psi

200

psi

0.40

0.45

0.47

0.49

0.53

0.56

0.50

0.56

0.59

0.61

0.66

0.71

0.60

0.67

0.71

0.74

0.79

0.85

0.65

0.73

0.77

0.80

0.86

0.92

0.75

0.84

0.89

0.92

0.99

1.06

0.85

0.95

1.01

1.04

1.13

1.20

0.90

1.01

1.07

1.10

1.19

1.27

1.00

1.12

1.18

1.23

1.32

1.41

1.10

1.23

1.30

1.35

1.46

1.56

1.20

1.34

1.42

1.47

1.59

1.70

1.25

1.39

1.48

1.53

1.65

1.77

1.35

1.51

1.60

1.65

1.79

-

1.50

1.68

1.77

1.84

-

-

1.65

1.84

-

-

-

-

1.75

-

-

-

-

-

Nozzle Flow Rate by Size

Figure 6. – Electrode tip gap and spacing

5/32” GAP

1/4” above

nozzle center

3/32” Nozzle-to-tip

Spacing

SK9664

Trained Service Technician’s Regular Maintenance

Use a 5/8” open-end wrench to carefully remove

the existing nozzle.

Inspect the nozzle adapter before installing the

new nozzle. If it is grooved or scratched on the

sealing surface, replace the nozzle line assem-

bly. If the surface is damaged, oil could leak at

the nozzle to adapter joint, causing serious com-

bustion problems.

Protect the nozzle orifi ce and strainer when in-

stalling. If the orifi ce gets dirt in it or is scratched,

the nozzle will not function properly.

To install a new nozzle, place a 3/4” open-end

wrench on the nozzle adapter. Insert the nozzle

into the adapter and secure fi nger tight. Finish

tightening with a 5/8” open-end wrench. Use care

to avoid bending the burner head support legs or

electrodes.

Do not over-torque the nozzle when install-

ing. This will cause deep grooves in the nozzle

adapter, preventing a seal when a new nozzle is

installed.

Carefully check and realign the electrode tips af-

ter replacing a nozzle, ensuring the electrode set-

tings comply with Figure 7.

If the head was removed when replacing the noz-

zle, carefully reconnect the head to the nozzle

adapter. Make sure to align the key in the support

leg with the keyway in the nozzle adapter and

to butt the head support to the nozzle adapter

shoulder, see Figure 8.

Check/Adjust Electrodes

Check the electrode tip settings, as shown in Fig-

ure 7. If necessary, adjust by loosening the elec-

trode clamp screw (Figure 8) and slide/rotate the

electrodes as necessary. When the adjustment is

complete, securely tighten the clamp screw.

Note that if the throttle cup is moved be sure to re-

position it with no gap between the nozzle adapter

and hub.

4.

5.

6.

7.

8.

9.

10.

•

Perform the following steps when replacing a nozzle.

Remove the nozzle line assembly to gain access

to the nozzle.

Use a 3/4” open-end wrench to hold the nozzle

adapter. DO NOT attempt to remove or replace

the nozzle without securing the adapter, as noz-

zle alignment could be seriously affected.

Do not squeeze the electrodes when handling

the nozzle line assembly. Excessive force could

change the electrode tip settings or damage the

ceramic electrode insulators.

1.

2.

3.

Use care when handling, removing and installing oil

nozzles.

Carefully follow the guidelines provided in this sec-

tion.

•

•

A damaged nozzle could cause impaired com-

bustion, sooting, puffback of hot gases, smoke,

oil leakage and potential fi re or asphyxiation

hazards.

Protect Nozzle from

Damage

!

!

CAUTION