Installation – Bendix Commercial Vehicle Systems AUTO SLACK ADJUSTER SERVICE MANUAL User Manual

Page 11

10

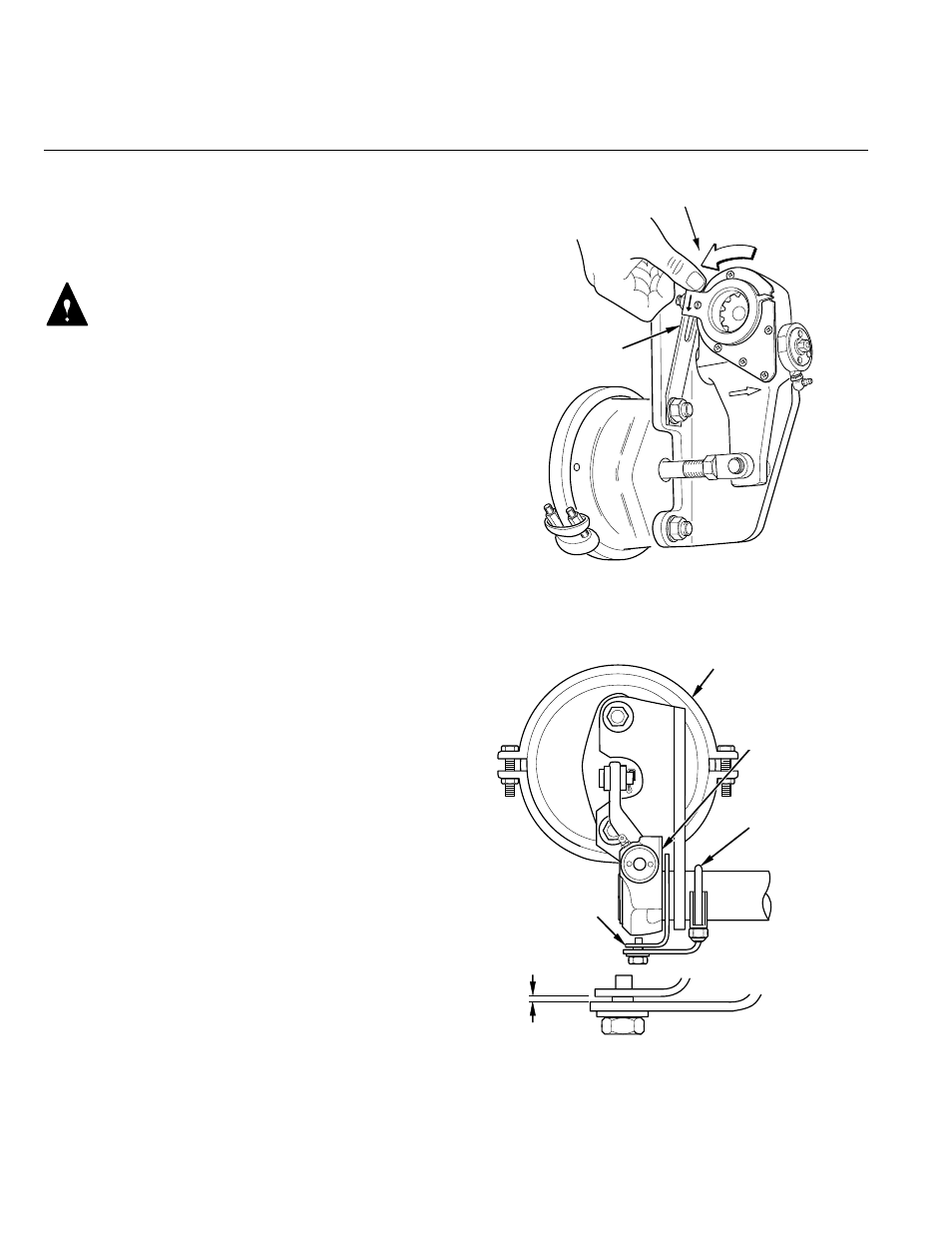

ROTATE

TO STOP

MOUNTING

BRACKET

Figure 16 Position Brake Adjuster

Position the Control Arm

6. Rotate the control arm counterclockwise away from

adjustment hex towards the air chamber until it comes to a

definite internal stop. (See Figure 16.) If necessary, use a

plastic mallet to tap the control arm into position.

Caution: Excessive positioning force may damage the

control arm. Most adjusters will be equipped with an

Installation Indicator. Indicator must fall within the

slot for proper installation. Incorrect control arm

position can cause tight or dragging brakes.

7. Tighten all control arm anchor bracket fastener(s).

Note: Make sure the control arm does not move from its

position while tightening the anchor bracket fasteners.

Note: Steer axle applications only–a gap of 1/16" should be

maintained between the anchor bracket and the control arm.

(See Figure 17.)

8. Adjust brakes by turning adjusting hex clockwise until the

lining contacts the drum. Then rotate the adjusting hex

counter clockwise 1/2 of a turn. A minimum of 13 ft. lbs. is

necessary to overcome the clutch and a racheting sound

will occur.

Final Inspection of the Self Adjusting Brake Adjuster

9. With full air pressure, release spring and service brake.

Verify that the installation indicator is within the slot.

Remove the clevis pin. The clevis hole and adjuster hole

should remain in alignment. If the air chamber clevis pulls

into the air chamber, repeat the installation procedure.

10. After final inspection, install the cotter pin into the clevis

pin. Verify that applied stroke is within the legal limits

for the air chamber being used.

AIR

CHAMBER

CLAMP-TYPE

BRACKET

ANCHOR

BRACKET

AUTOMATIC

SLACK

ADJUSTER

1/16"

GAP

Figure 17 Proper Anchor Bracket and Control Arm Gap

Installation

SELF ADJUSTING

BRAKE ADJUSTER