Premature lining wear, Brake systems diagnostic guide – Bendix Commercial Vehicle Systems BRAKE SYSTEM TROUBLESHOOTING GUIDE User Manual

Page 19

17

BRAKE SYSTEMS DIAGNOSTIC GUIDE

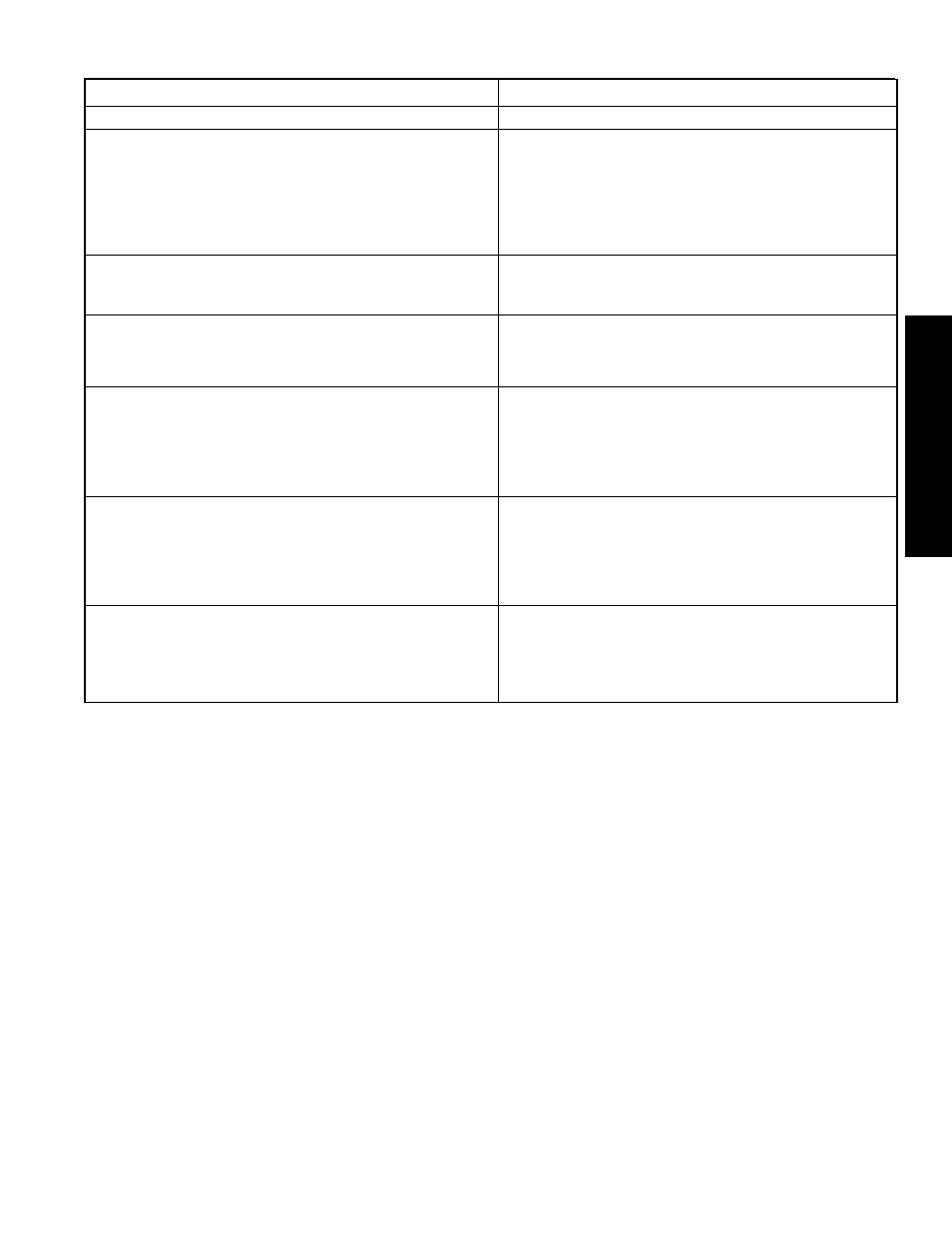

POTENTIAL CONDITION/CAUSE

ACTION (SERVICE MANUAL SECTION)

Dragging brakes

See DRAGGING BRAKES

Poor lining-to-drum contact. Linings are tapered

across width:

• Bell-mouthed drum

Replace drum (3)

• Bent brake spider

Replace spider (3,6)

• Bent or stretched brake shoe

Replace shoe (3,6)

• Loose wheel bearing

Torque spindle nuts and check end play (6)

• Worn or damaged cam

Replace cam (3,6)

Shoe-to-shoe variation:

• Mismatched lining friction codes

Replace lining(s) with proper friction code (5)

• Stretched shoe

Replace shoe (3,6)

Brake components:

• Flat spots on cam or roller

Replace cam or roller (3,6)

• Worn anchor pin

Replace anchor pin (3,6)

• Worn camshaft or bushings

Replace camshaft and bushings (5)

Unequal wear on side-to-side brakes for same axle:

• Mismatched lining friction codes

Replace lining(s) with proper friction code (5)

• Seized or binding camshaft

Clean and lubricate camshaft (2)

• Brake drum surface in poor condition

Replace drum (3)

• Loose wheel bearing

Torque spindle nuts and check end play (6)

• Performing downgrade braking using light drag

Use snub method on downgrades

Slack adjuster not set properly:

• Incorrect installation of slack adjuster

Install slack adjuster properly (3,6)

• Incorrect in-service adjustment

Check and correct adjustment procedure (2)

• Incorrect setup of external reference control arms

Perform correct setup procedure (2)

(Eaton-Haldex)

• Broken or bent parts

Replace damaged parts as required (3,6)

Wear on edge of lining:

• Wrong lining width

Replace lining (5)

• Wrong drum

Replace drum (3)

• Loose bearing adjustment. Bearing spacer missing or too thin

Replace spacer and torque spindle nuts. Check end

play (6)

PREMA

TURE LINING WEAR