Bendix, Ad-is – Bendix Commercial Vehicle Systems AD-IS AIR DRYER AND RESERVOIR SYSTM User Manual

Page 14

14

BENDIX

®

AD-IS

®

AIR DRYER AND RESERVOIR SYSTEM

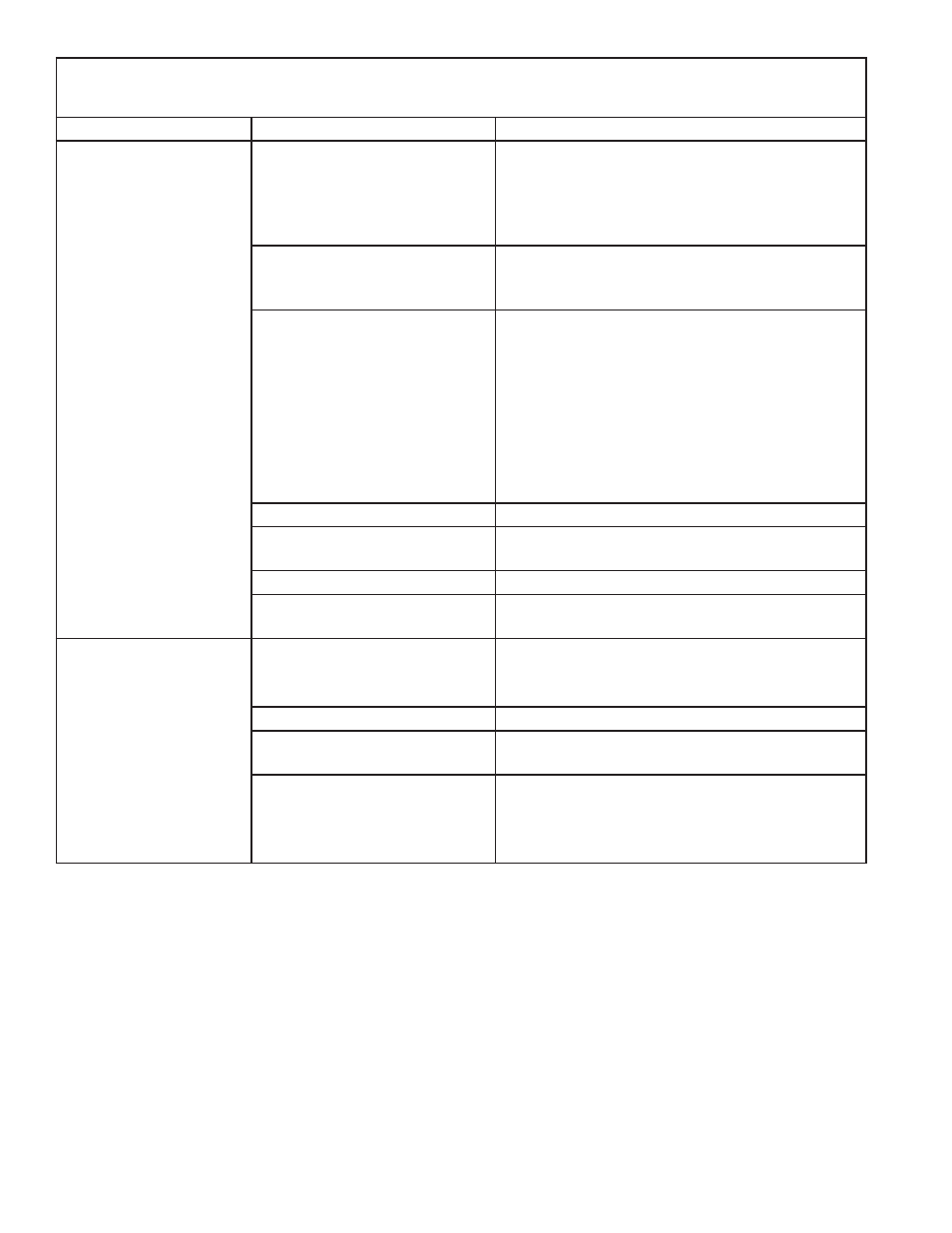

TROUBLESHOOTING CHART

SYMPTOM

CAUSE

REMEDY

2. Water in the vehicle

reservoirs

A. Maximum air dryer inlet temperature is

exceeded due to improper discharge

line length.

A. Check for excessive carbon build up in the compressor

discharge line. Replace if required. Make certain that the

discharge line length is at least 6 ft. Increase the discharge

line length and/or diameter to reduce air dryer inlet

temperature.

B. Air system charged from outside

air source (outside air not passing

through air dryer).

B. If system must have outside air fill provision, outside air should

pass through air dryer.

C. Excessive air usage - Air dryer not

compatible with the vehicle air system

requirement (Improper air dryer/

vehicle application)

C. Refer to the Bendix Advanced Troubleshooting Guide for Air

Brake Compressors (BW1971) for proper application of the

Bendix

®

AD-IS

®

air dryer and reservoir system. An extended

purge model (Bendix

®

AD-IS

®

EP) is available for many higher

air usage vehicles, such as city buses and construction

vehicles.

If the vehicle is equipped with high air usage accessories,

such as trailer pump-off systems or central tire inflation, the

air for these accessories must by-pass the dryer reservoir

system.

D. Desiccant requires replacement.

D. Replace the desiccant cartridge assembly.

E. Air by-passes desiccant cartridge

assembly.

E. If the vehicle uses a Holset compressor, inspect the feedback

check valve for proper installation and operation.

F. Air dryer not purging.

F. Refer to Symptom 6.

G. Purge (air exhaust) time is insufficient

due to excessive system leakage.

G. Refer to Symptom 1.

3. Safety valve on the air dryer

is “popping off” or exhausting

air.

A. Defective AD-IS air dryer and reservoir

system delivery check valve.

A. Test to determine if air is passing through check valve. Repair

or replace. Refer to Symptom 1, Remedy B.

B. Safety valve setting too low (<150 p.s.i.) B. Replace the safety valve.

C. System pressure too high (>135 p.s.i.) C. Test with an accurate gauge. Replace the governor if

necessary.

D. Excessive pressure pulsations from

compressor. (Typical single cylinder

type).

D. Increase volume in discharge line. This can be accomplished

by adding a 90 cubic inch (or larger) reservoir between the

compressor and the AD-IS

®

air dryer and reservoir system.