Operation – Bendix Commercial Vehicle Systems TU-FLO 1000 AIR COMPRESSOR User Manual

Page 3

3

had either die cast aluminum, cast ductile iron, or forged

steel rods which were not rifle drilled but were drilled at the

top of the rod. The wrist pins and bushings are lubricated

by oil dripping from a drip-boss on the piston into a

“catch-funnel” at the top of the rod and through the drilled

passage to the bushings and pins. (SEE FIG. 7)

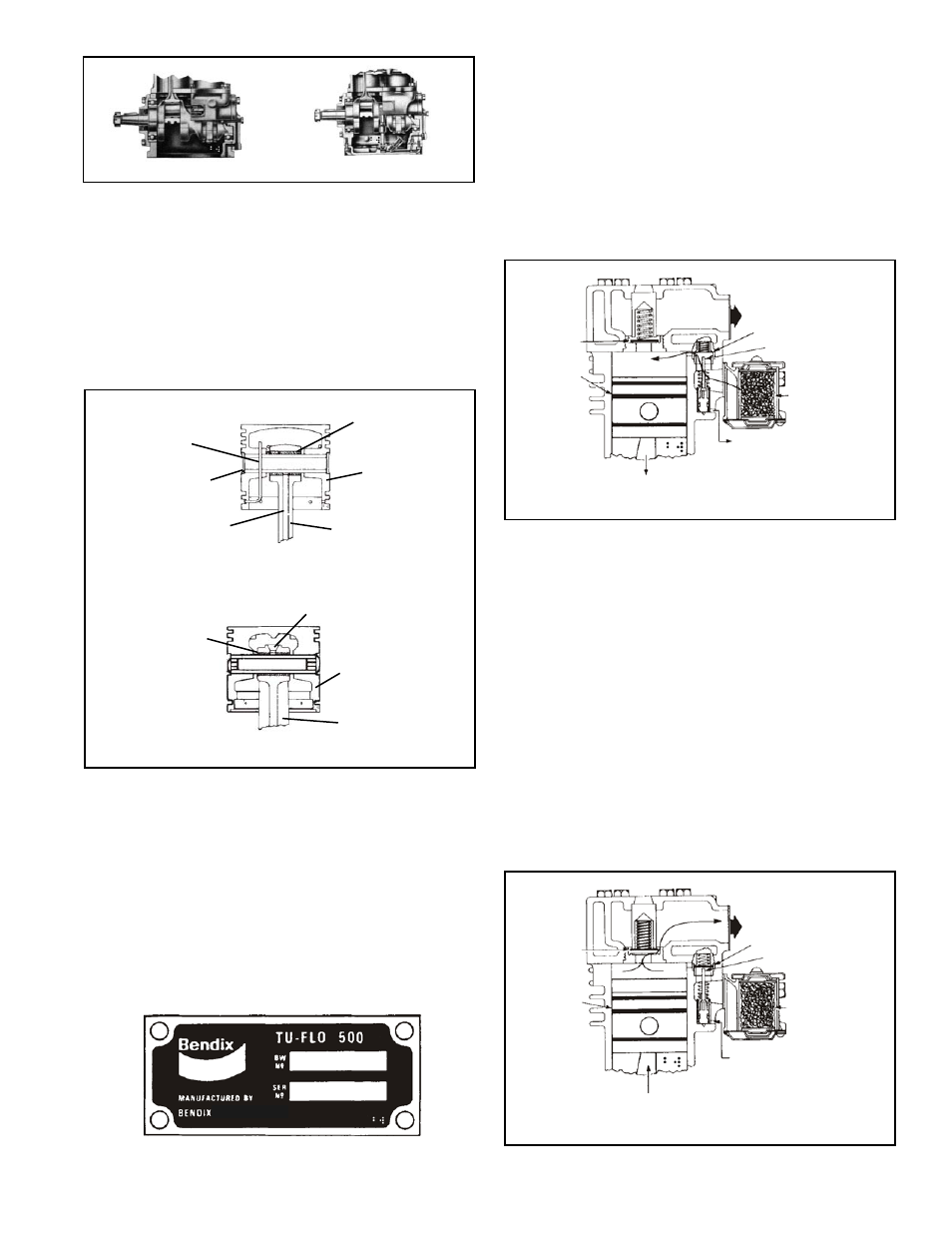

A nameplate is attached to the crankcase of all compressors.

It shows the piece number, type and serial number (Fig. 8).

A nameplate with a black background denotes a new

compressor, whereas a nameplate with a red background

designates that the compressor is a factory reconditioned

unit. All compressors are identified by the piece number

which is the number to use when reference is made to a

particular compressor. The type and serial number is

supplementary information.

OPERATION

GENERAL

All compressors run continuously while the engine is running,

but actual compression of air is controlled by a governor,

which stops or starts the compression of air by loading or

unloading the compressor in conjunction with its unloading

mechanism. This is done when the air pressure in the system

reaches the desired maximum or minimum pressures.

INTAKE AND COMPRESSION (Loaded)

During the down stroke of the piston, a slight vacuum created

above the piston causes the inlet valve to move off its seat.

Atmospheric air is drawn in through the compressor intake,

by the open inlet valve, and on top of the piston (Fig. 9). As

the piston starts its upward stroke, the air that was drawn in

on the down stroke is being compressed. Now, air pressure

on top of the inlet valve plus the force of its spring, returns

the inlet valve to its seat. The piston continues the upward

stroke and compresses the air sufficiently to overcome the

discharge valve spring and unseat the discharge valve. The

compressed air then flows by the open discharge valve, into

the discharge line and on to the reservoirs (Fig. 10).

FIGURE 5

ENGINE LUBRICATED TYPE

FIGURE 6

SELF-LUBRICATED TYPE

FIGURE 9

FIGURE 10

DISCHARGE

VALVE

PISTON

STROKE

TO GOVERNOR

INTAKE

STRAINER

UNLOADER PLUNGER

INLET VALVE

TO RESERVOIR

INTAKE

DISCHARGE

VALVE

PISTON

STROKE

TO GOVERNOR

INTAKE

STRAINER

UNLOADER PLUNGER

INLET VALVE

TO RESERVOIR

COMPRESSION

FIGURE 8 - COMPRESSOR NAMEPLATE

FIGURE 7- PISTONS & CONNECTING RODS

NEW DESIGN

WRIST PIN

BUSHING

“CATCH FUNNEL”

DIE CAST

PISTON

DIE CAST

CONNECTING ROD

OLD DESIGN

OIL

PASSAGE

WRIST PIN

WRIST PIN

BUSHING

PISTON WRIST PIN

LOCK WIRE

CAST IRON

PISTON

STEEL

CONNECTING

ROD