Bendix, Ad-is – Bendix Commercial Vehicle Systems AD-IS AIR DRYER AND RESERVOIR SYSTM User Manual

Page 13

13

BENDIX

®

AD-IS

®

AIR DRYER AND RESERVOIR SYSTEM

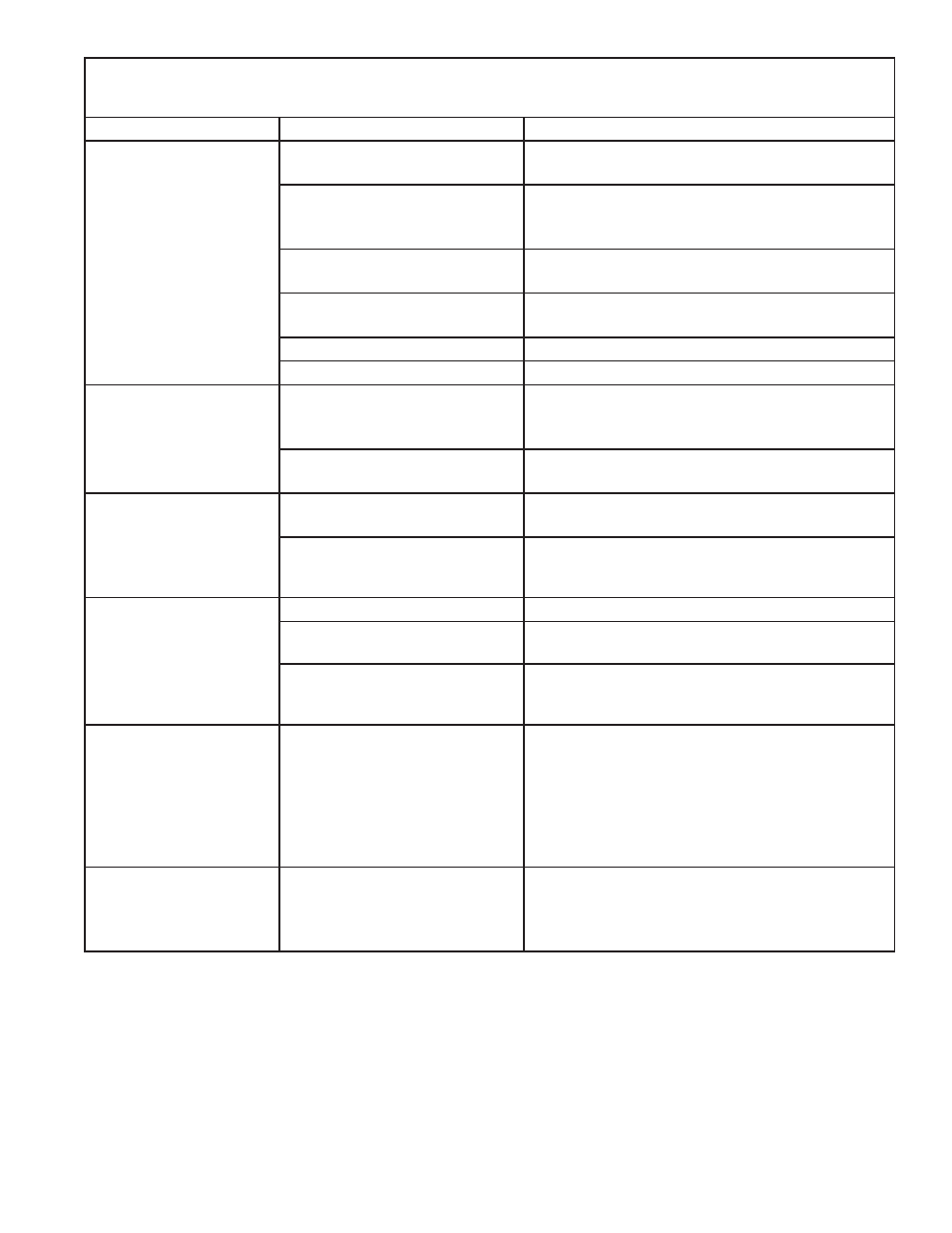

TROUBLESHOOTING CHART

SYMPTOM

CAUSE

REMEDY

5. Cannot build system air

pressure.

A. Supply pressure to the air dryer is not

suffi cient.

A. Ensure the supply pressure to the air dryer is greater than

110 psi after the system charges.

B. Kinked or blocked (plugged) discharge

line.

B. Check to determine if air passes through discharge line.

Check for kinks, bends, excessive carbon deposits, or ice

blockage.

C. Excessive bends in discharge line

(water collects and freezes).

C. Discharge line should be constantly sloping from compressor

to air dryer with as few bends as possible.

D. Pressure protection valve(s) in air

dryer will not open.

D. Replace air dryer (pressure protection valves are not

serviceable).

E. Refer to Symptom 4.

E. Refer to Symptom 4, Remedy A.

F. Refer to Symptom 7.

F. Refer to Symptom 7, Remedies A and B.

6. Air dryer does not purge or

exhaust air.

A. Faulty air dryer purge valve.

A. After determining air reaches purge valve control port by

installing a T-fi tting with a pressure gauge into the governor

unloader port, repair purge valve if necessary.

B. See Causes B, E, and F for Symptom

#4.

B. Refer to Symptom 4, Remedies B, E, and F.

Also refer to Symptom 1, Remedy B.

7. Desiccant material being

expelled from air dryer purge

valve exhaust (may look like

whitish liquid or paste or

small beads.)

A. Faulty dryer cartridge.

A. Replace the Bendix

®

AD-IS

®

air dryer cartridge or AD-IS air

dryer.

B. Excessive dryer vibration.

B. Check the AD-IS air dryer mounting for looseness or damage.

Repair mounting and replace cartridge.

8. Unsatisfactory desiccant life. A. Excessive system leakage.

A. Refer to Symptom 1, Remedy A.

B. Wrong vehicle application for AD-IS

®

air dryer.

B. Refer to Symptom 2, Remedy C.

C. Compressor passing excessive oil.

C. Check for proper compressor installation; if symptoms

persist, replace compressor. Refer to Bendix Advanced

Troubleshooting Guide for Air Brake Compressor (BW1971).

9. “Pinging” noise excessive

during compressor loaded

cycle.

A. Single cylinder compressor with high

pulse cycles.

A. A slight “pinging” sound may be heard during system build

up when a single cylinder compressor is used. If this sound

is deemed objectionable, it can be reduced substantially by

increasing the discharge line volume.

This can be accomplished by adding a 90 cubic inch (or

larger) reservoir between the compressor and the AD-IS

air

dryer and reservoir system.

10. The air dryer purge piston

c y c l e s r a p i d l y i n t h e

compressor unloaded (non-

compressing) mode.

A. Compressor fails to “unload”.

A. Check air hose from governor to compressor for a missing,

kinked or restricted line. Install or repair air hose.

Repair or replace compressor unloader.