Port designation, Electrical control – Bendix Commercial Vehicle Systems M-30 ANTILOCK MODULATOR ASSY 9/04 User Manual

Page 8

8

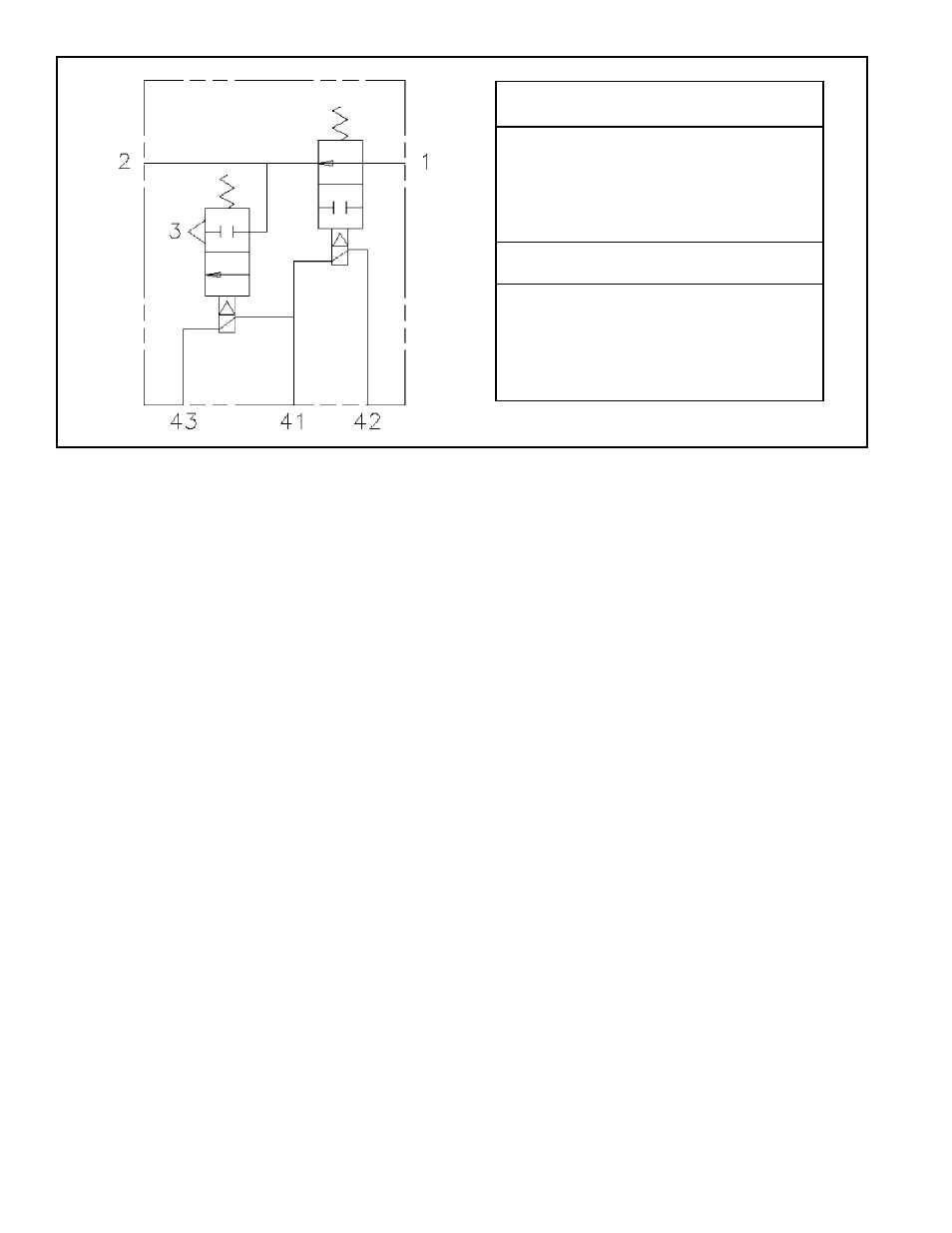

FIGURE 12: M-30

™

MODULATOR DIN SYMBOL

BW2085 © 2004 Bendix Commercial Vehicle Systems LLC All rights reserved. 9/2004 Printed in U.S.A.

2. Proceed to the modulator in question and inspect its

wiring connector. Disconnect the connector and test

the resistance between the pins ON THE MODULATOR.

Refer to figures 11 and 12.

A. HOLD TO SOURCE (41-42): Read 3.5 to 5 OHMS

B. EXHAUST TO SOURCE (43-41): Read 3.5 to 5 OHMS

C. EXHAUST TO HOLD (43-42): Read 7 to 10 OHMS

D. Individually test the resistance of each pin to vehicle

ground and note there is NO CONTINUITY.

If the resistance readings are as shown, the wire harness

leading to the modulator may require repair or

replacement. Before attempting repair or replacement

of the wire harness, refer to the test procedures specified

for the antilock controller in use for possible further testing

that may be required to substantiate the wire harness

problem. If the resistance values are NOT AS STATED,

replace the modulator.

MODULATOR REMOVAL

1.

Locate the modulator that will be replaced and clean

the exterior.

2.

Identify and mark or label all air lines and their respec-

tive connections on the valve to facilitate ease of

installation.

3.

Disconnect both air lines and the electrical connector.

4.

Remove the modulator from the vehicle.

5.

Remove all air line fittings and plugs. These fittings

will be re-used in the replacement modulator.

PORT DESIGNATION

SUPPLY

1

DELIVERY

2

EXHAUST

3

ELECTRICAL CONTROL

SOURCE 41

HOLD 42

EXHAUST 43

MODULATOR INSTALLATION

1.

Install all air line fittings and plugs, making certain thread

sealing material does not enter the valve.

2.

Install the assembled valve on the vehicle.

3.

Reconnect both air lines to the valve using the identifi-

cation made during VALVE REMOVAL step 5.

4.

Reconnect the electrical connector to the modulator.

5.

After installing the valve, test all air fittings for excessive

leakage and tighten as needed.

TECHNICAL INFORMATION

Porting

1 Supply Port (from brake, relay

or quick release valve) - 1/2" NPT

1 Delivery Port (brake actuator) - 1/2" NPT

Optional:

Push-to-connect for 1/2" tubing

Solenoid Voltage : 12 Volts DC Nominal

Weight: 1.7 pounds

Maximum Operating Pressure: 150 psi Gauge

Operating Temperature Range: -40 to 185 degrees

Fahrenheit

Pressure Differential: 1 psi maximum (supply to delivery)

Mounting Hole Sizes

0.33" diameter thru body