Bendix Commercial Vehicle Systems MV-3 DASH CONTROL MODULE 3/04 User Manual

Page 6

6

ASSEMBly

DuAl CIRCuIT SuPPly VAlVE

1. lubricate all o-rings and bores with silicone lubricant.

(Bendix piece number 291126 or Dow Corning 55-M.)

2. Place the check valve (17) into its seat in the body with

its flat surface facing upward. If necessary, reach into

the body to make sure the valve is seated evenly in the

bore.

3. Install o-rings (24 & 13) onto the check valve (23). Then

install the assembly into its cavity in the Bendix

®

MV-3

®

valve body.

4. Install the snap ring (22) making sure it is fully seated

in its groove.

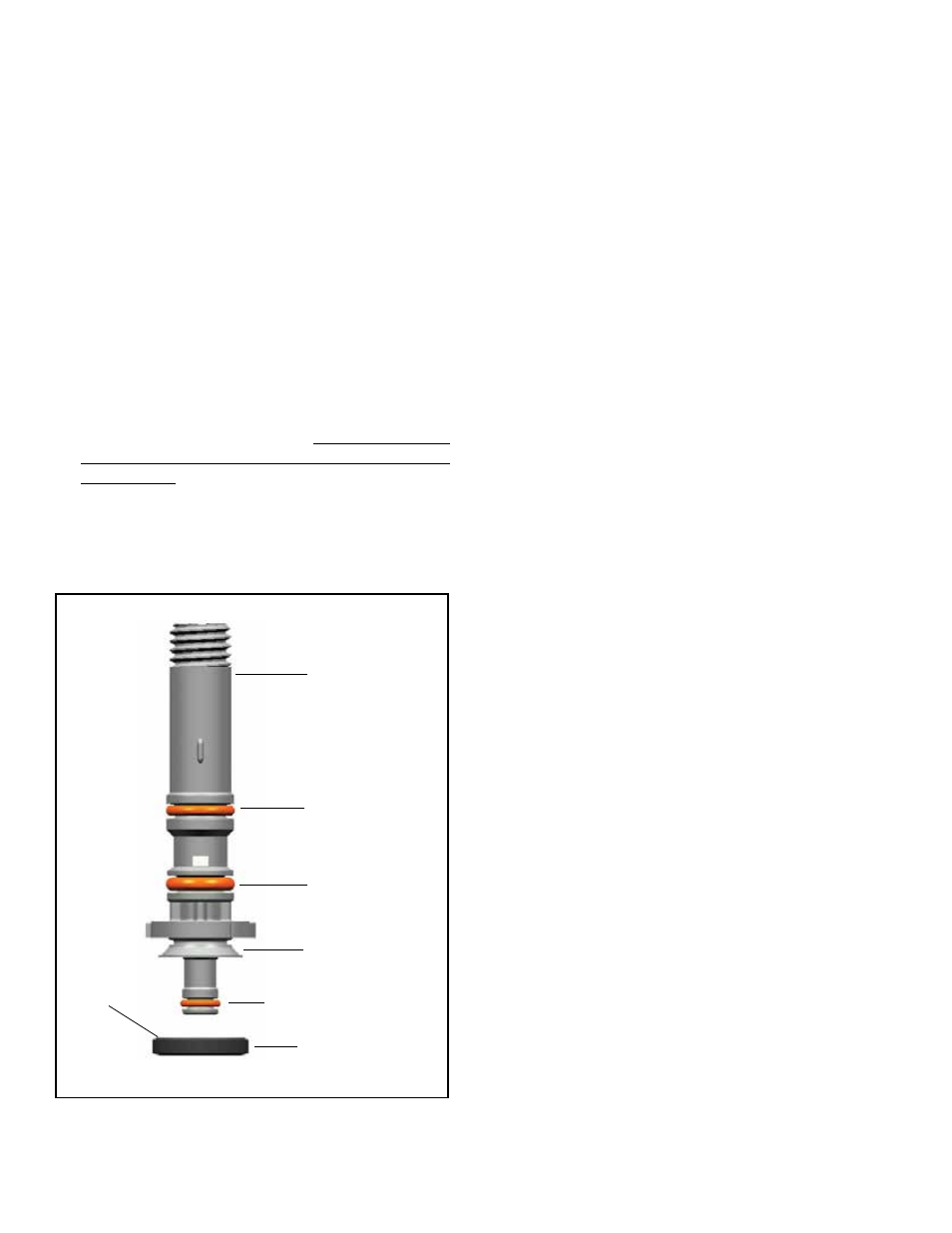

SPOOlS

1. Install o-rings (18,19 & 20) and the exhaust seal (21)

onto the stem of the plungers (15).

CAuTION: The exhaust seal (21) must be installed so

that its beveled surface mates with the beveled surface

of the plunger (Figure 7).

2. Install the o-ring (16) onto the guide spool (14). Install

the guide spool assembly over the threaded end of the

plunger (15) and press down firmly until it contacts the

plunger flange.

FIGURE 7 -

PlunGer and exhaust seal

i.D.

BeVel

21

eXhauSt Seal

20

o-rinG

MatinG

eXhauSt

Seal

BeVel

19

o-rinG

18

o-rinG

15

PlunGer

3. Install the spring (12) over the boss in the bottom of

the spool cavity in the body of the MV-3 valve. Place

the spool assembly into the body, keeping the spool

square to the body press and turn the stem until the

spool is fully seated in its cavity. Note the assembly is

keyed and may only be installed one way.

4. Repeat Steps 1, 2, and 3 with the remaining components

for the opposite spool.

ShuTTlE AND ChECk VAlVE

1. Install the o-ring (11) into its groove on the piston (7) and

o-ring (6) onto the cap (5).

2. Install the spring (8) on the piston (7) and spring (9) on

the boss of the check valve (10).

3. Install the spring and check valve into its cavity in the

body of the MV-3 valve (tapered end of check valve to

enter cavity first). Make sure the spring (9) is centered

in the bore.

4. Install the piston assembly into the cavity making sure

the spring (9) mates with the bore of the piston.

5. Install the cap (5) with o-ring (6).

FINAl ASSEMBly

1. Install the cover plate (3) onto the valve body and retain

with the six Phillips head screws. Torque to 30 in. Ibs.

2. Attach the red (1) and yellow (2) buttons onto the

threaded stems of the spools, making sure that they are

oriented correctly as noted in Step 1 of Disassembly

procedure.

3. Reattach the MV-3 valve to the dash using the hardware

removed in Step 2 of Disassembly. If air lines were

removed during disassembly, reconnect to ports marked

during disassembly. When reconnecting threaded ports

use a liquid thread sealing compound, attach the air

line until it is hand tight and then turn approximately

one and a half turns further (or using a maximum of 10

ft.-lbs. torque - Note: overtorquing will crack the port).

SERVICE TEST

Repeat the Operational Test procedures. Test drive vehicle

at slow speed in a safe area prior to placing it back into

service.

For additional information refer to Technical Bulletin -

Bendix Dash Valve Trip Pressure TCH-003-051.