Bendix Commercial Vehicle Systems INLET REG VALVE COMP 3/04 User Manual

Page 5

5

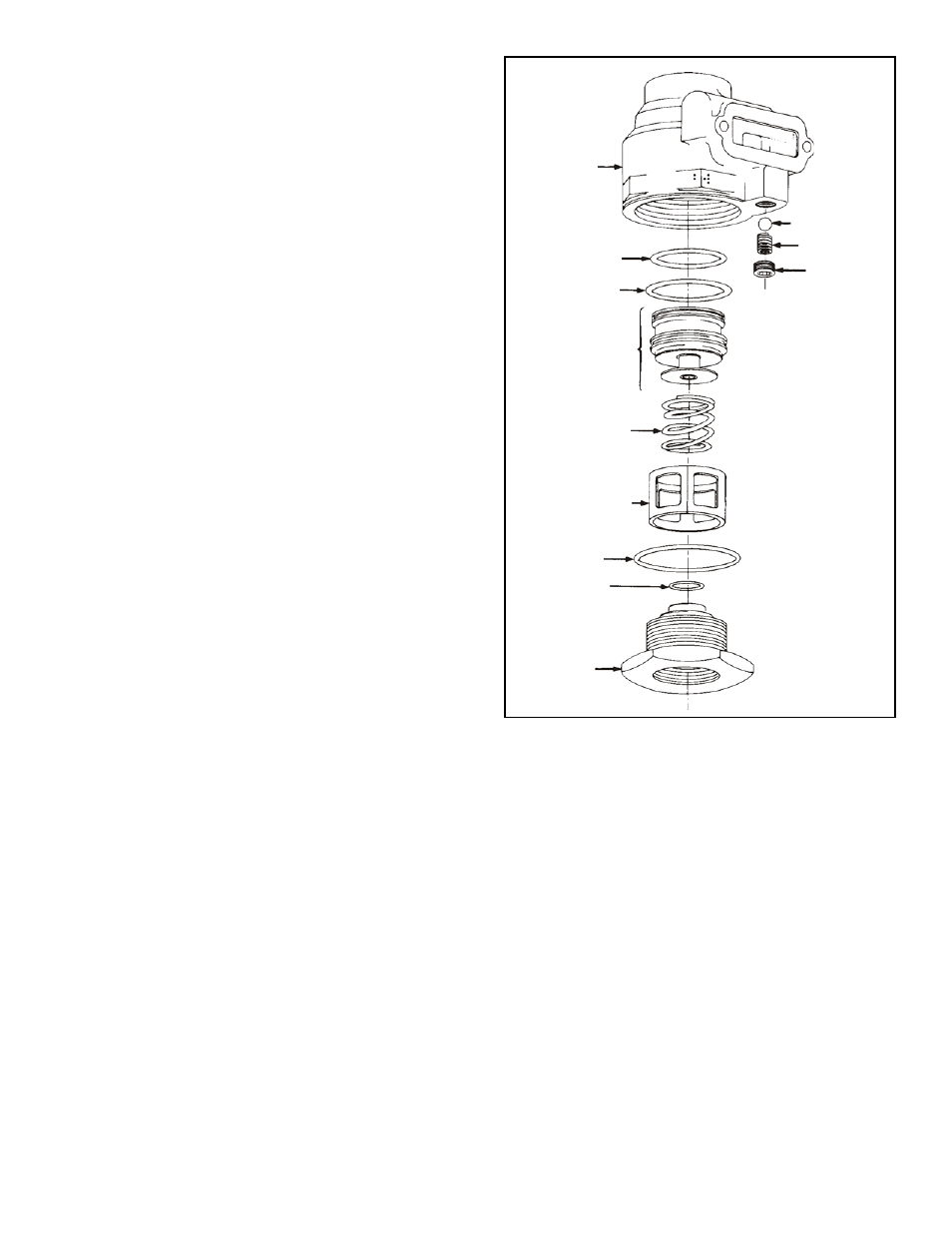

FIGURE 9 - INLET REGULATING VALVE

4. Adjust shop air to the IRV

™

valve to 5 psi and allow the

compressor to build the vehicle air system pressure to

governor cut-out and note that the compressor unloads.

With the compressor unloaded increase the shop air

pressure to the IRV

™

valve in 5 psi increments up to 25

psi. Pause 15-20 seconds at each pressure setting and

note that the compressor inlet pressure as indicated by

test gauge ‘A’ is 12 psi or less. If the pressure exceeds

12 psi more than momentarily, the IRV

™

valve should be

repaired or replaced.

Note: The tests described in this step must be made

with the compressor unloaded.

5. Test the function of the IRV

™

valve safety. Turn off the

engine and simultaneously apply shop air pressure to

the IRV

™

valve turbo supply port and to the compressor

inlet (through the inlet adapter 236701). Beginning at 5

psi, slowly raise the pressure at both locations

simultaneously until an exhaust of air is heard at the

IRV

™

valve’s safety valve. Note the pressure on gauge

‘A’ when the exhaust is heard. If exhaust occurs below

18 psi or above 25 psi, the IRV

™

valve must be repaired

or replaced.

REMOVAL

1. Park the vehicle on a level surface and block the wheels

and/or hold the vehicle by means other than the air

brakes.

2. Drain the air pressure from all vehicle reservoirs.

3. Disconnect the turbocharged air line at the 3/4 inch

NPT turbo supply port of the IRV

™

valve.

4. Remove the two cap screws that secure the IRV

™

valve,

then remove the valve itself.

INSTALLATION

1. Install a new gasket on the mounting flange of the IRV

™

valve and using two cap screws secure the IRV

™

valve.

Note: If 5/16 inch cap screws are used to secure the

IRV

™

valve to the compressor inlet, torque the cap screws

to between 125 and 150 pound inches.

2. Reconnect the turbocharged air line to the 3/4 inch NPT

turbo supply port of the IRV

™

valve.

3. Before placing the vehicle in service, close all reservoir

drain cocks and build air system pressure to governor

cut-out.

DISASSEMBLY (FIGURE 9)

The following disassembly instructions are presented for

reference purposes. Actual disassembly should not be

undertaken without having the necessary maintenance kit

and instructions available. Refer to Figure 9 throughout

disassembly.

1. Using an adjustable or two inch wrench remove the cap

nut from the body.

2. Remove the spring and spacer.

3. Remove the large diameter o-ring located beneath the

hex head of the cap nut.

4. Taking care not to damage the roll crimp of the cap nut,

remove the small diameter o-ring which serves as the

valve seat.

5. Gently tap the open end of the valve body on a nonmetallic

surface in order to remove the valve and piston assembly.

6. Remove the large and small diameter o-rings from the

exterior of the valve and piston assembly. NOTE: No

further disassembly of the valve and piston assembly

should be attempted. The detail parts of this assembly

are NON-SERVICEABLE.

7. Using a 3/16 inch Allen wrench, remove the exhaust

plug.

8. Remove the valve spring and valve.

BODY

O-RING

VALVE &

PISTON

ASSEMBLY

SPACER

O-RING

SPRING

VALVE SEAT

(O-RING)

CAP NUT

EXHAUST

PLUG

SPRING

VALVE

O-RING